Product Description

| Item Name | New Pure Titanium Necklace Flat Long O-Chain European Hip Hop Fashion Couple Industrial Versatile Necklace Retro Silver Chain |

| Item Number | TINL2383 |

| Material | Pure Titanium |

| Color | Silver |

| MOQ | 20pcs |

| Pakage | PE Bag and Export Carton |

| Delivery Time | 7-10Days |

| Payment | T/T, Union Western, Paypal |

| Shipping | DHL,UPS,Fedex,EMS |

1) Fashion and High Quality Necklace.

2) Delivery time: within 15-20days

3)If you need more styles and price,please ask us to send our catalogues.

4) Good Polish with quality, Polished by our professlonal staff

5) PVD plated, Won’t fade in 2 years.

6)High-end and fashionable, A good gift for wedding

7) Packaging: PE bag and export carton

Our services:

1)OEM&ODM orders are welcome

2)Preproduction samples will be a vailable before the production

3)Professlonal staff strictly control the quality.

4)The products will be double check before the final packing

5)Excellent after-sales services

How to work with us?

1)Tell us which products do you need

2)If you have any questions,Please tell us ,We will answer all your questions in detail

3)Discuss and decide the price

4)We production the goods

5)30% deposit in advance,The 70% balance pay before shipment

6)Delivery products by DHL/UPS/FedEx/EMS/Aramex

7)After sales services

How to contact us?

1) Send inquiry to us, we will reply you at the frist time.

2) Contact us, we will answer your questions detailedly.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Titanium |

|---|---|

| Pendant Shape: | No |

| Suitable for: | Female, Male, Children, Elderly |

| Style: | Elegant |

| Usage: | Decoration, Health |

| Color: | Pure Titanium |

| Customization: |

Available

| Customized Request |

|---|

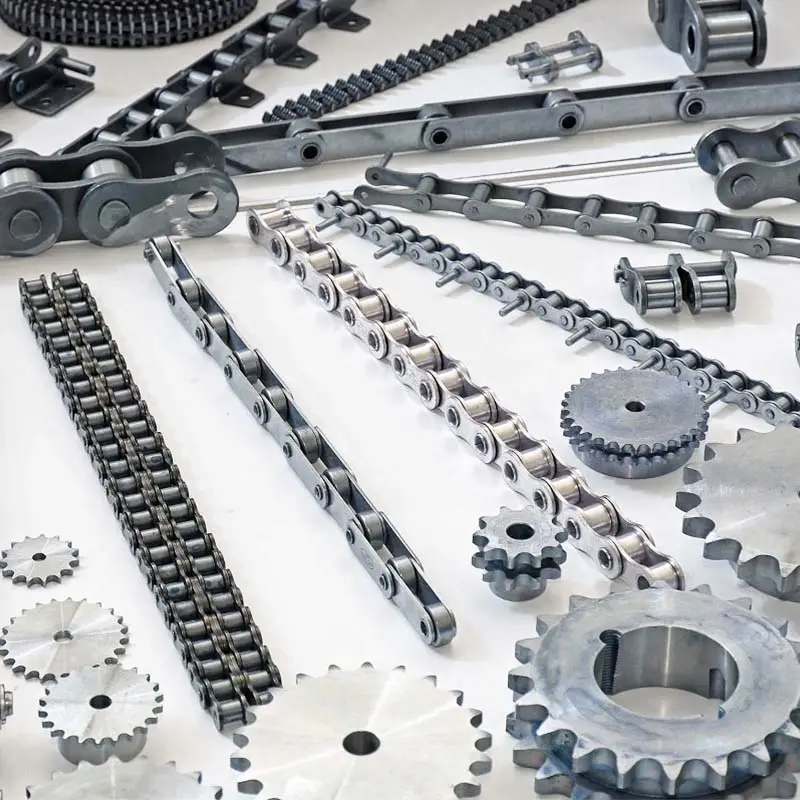

What are the advantages of using a silent chain in an industrial application?

A silent chain, also known as an inverted tooth chain or toothed belt, offers several advantages when used in industrial applications:

1. Quiet operation: Silent chains are designed to minimize noise during operation. The toothed design allows for smooth engagement and disengagement of the chain, resulting in reduced noise levels compared to other chain types. This is particularly beneficial in applications where noise reduction is important, such as in indoor environments or noise-sensitive areas.

2. High load-carrying capacity: Silent chains are capable of carrying heavy loads due to their robust construction. The interlocking toothed design provides excellent power transmission capabilities, allowing for efficient transfer of high torque and load-bearing capacity. This makes silent chains suitable for applications that require heavy-duty performance.

3. Precise positioning and synchronization: Silent chains provide precise positioning and synchronization between the driving and driven components. The toothed profile ensures accurate motion control, making them ideal for applications that require precise timing, such as conveyors, robotics, and automated systems.

4. Low maintenance requirements: Silent chains require minimal maintenance compared to other chain types. The toothed design reduces the need for frequent lubrication, tensioning, and adjustments. This results in lower maintenance costs and less downtime for maintenance activities.

5. High efficiency: Silent chains have high power transmission efficiency due to their positive engagement between the teeth. This means that less energy is wasted during operation, resulting in improved overall system efficiency.

6. Durability and longevity: Silent chains are designed to withstand demanding industrial environments. They are constructed from high-quality materials, such as alloy steel or stainless steel, which provide excellent strength, wear resistance, and corrosion resistance. This ensures a long service life and reduces the need for frequent replacements.

7. Wide range of applications: Silent chains can be used in various industrial applications, including power transmission systems, conveyors, packaging machinery, printing presses, machine tools, and automotive timing systems. Their versatility makes them suitable for a wide range of industries, including manufacturing, automotive, food processing, and pharmaceutical.

Overall, the advantages of using a silent chain in an industrial application include quiet operation, high load-carrying capacity, precise positioning, low maintenance requirements, high efficiency, durability, and versatility. These benefits make silent chains a preferred choice for many industrial applications where reliable and efficient power transmission is required.

How does an industrial chain compare to other types of power transmission systems?

An industrial chain is a type of power transmission system that offers several advantages compared to other systems:

- Strength and durability: Industrial chains are designed to handle heavy loads and withstand tough operating conditions. They are known for their high strength and durability, making them suitable for demanding industrial applications.

- Efficiency: Industrial chains provide efficient power transmission, minimizing energy loss during operation. They offer high mechanical efficiency, which is especially important in applications that require precise and consistent power transfer.

- Flexibility: Industrial chains are flexible in terms of design and configuration. They can be easily adapted to various applications and can transmit power over long distances, making them suitable for a wide range of industrial machinery and equipment.

- Cost-effectiveness: Industrial chains are often cost-effective compared to alternative power transmission systems. They are relatively simple in design, easy to manufacture, and have a lower initial cost. Additionally, their durability and longevity reduce the need for frequent replacements, resulting in long-term cost savings.

- Reliability: Industrial chains are known for their reliability and consistent performance. When properly maintained and operated within their load and speed limits, they can provide reliable power transmission for extended periods.

- Versatility: Industrial chains can accommodate various environmental conditions, including high temperatures, corrosive environments, and high-speed applications. They can be made from different materials and configured with specific features to suit specific application requirements.

While industrial chains offer numerous advantages, it is essential to consider specific application needs and requirements when selecting a power transmission system. Factors such as load capacity, operating environment, speed, and precision may influence the suitability of an industrial chain compared to alternatives such as belts, gears, or shafts.

How do you select the right industrial chain for a specific application?

Selecting the right industrial chain for a specific application involves considering several factors to ensure optimal performance and longevity. Here are the steps to guide you in the selection process:

- Identify the application requirements: Understand the specific needs of your application, such as load capacity, speed, operating environment, and desired functionality.

- Determine the chain type: Based on the application requirements, choose the appropriate chain type, such as roller chains, conveyor chains, leaf chains, or specialty chains.

- Consider chain material: Evaluate the compatibility of the chain material with the operating environment, including factors like corrosion resistance, temperature resistance, and chemical resistance.

- Evaluate chain strength: Determine the required chain strength based on the anticipated loads and forces encountered in the application. Consider factors such as shock loads, tension, and fatigue resistance.

- Calculate chain length: Calculate the required chain length by considering the distance between sprockets, the desired tension, and any adjustments required for installation and maintenance.

- Check for specific features: Determine if any specific features are necessary for the application, such as self-lubricating capabilities, noise reduction, or specialized attachments.

- Consult manufacturer guidelines: Refer to the manufacturer’s guidelines and specifications for the selected chain type to ensure it meets the required standards and specifications.

- Consider maintenance and serviceability: Evaluate the chain’s maintenance requirements and ease of servicing to ensure it can be properly maintained throughout its lifespan.

- Verify compatibility: Confirm the compatibility of the selected industrial chain with the accompanying sprockets, gears, or other components to ensure proper engagement and operation.

- Consider cost-effectiveness: Assess the overall cost-effectiveness of the chain, considering factors such as initial cost, maintenance expenses, and expected lifespan.

By following these steps and considering the specific requirements of your application, you can select the right industrial chain that meets your operational needs and ensures reliable and efficient performance.

editor by CX 2024-04-04