Product Description

| Item Name | New Pure Titanium Necklace Flat Long O-Chain European Hip Hop Fashion Couple Industrial Versatile Necklace Retro Silver Chain |

| Item Number | TINL2383 |

| Material | Pure Titanium |

| Color | Silver |

| MOQ | 20pcs |

| Pakage | PE Bag and Export Carton |

| Delivery Time | 7-10Days |

| Payment | T/T, Union Western, Paypal |

| Shipping | DHL,UPS,Fedex,EMS |

1) Fashion and High Quality Necklace.

2) Delivery time: within 15-20days

3)If you need more styles and price,please ask us to send our catalogues.

4) Good Polish with quality, Polished by our professlonal staff

5) PVD plated, Won’t fade in 2 years.

6)High-end and fashionable, A good gift for wedding

7) Packaging: PE bag and export carton

Our services:

1)OEM&ODM orders are welcome

2)Preproduction samples will be a vailable before the production

3)Professlonal staff strictly control the quality.

4)The products will be double check before the final packing

5)Excellent after-sales services

How to work with us?

1)Tell us which products do you need

2)If you have any questions,Please tell us ,We will answer all your questions in detail

3)Discuss and decide the price

4)We production the goods

5)30% deposit in advance,The 70% balance pay before shipment

6)Delivery products by DHL/UPS/FedEx/EMS/Aramex

7)After sales services

How to contact us?

1) Send inquiry to us, we will reply you at the frist time.

2) Contact us, we will answer your questions detailedly.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Titanium |

|---|---|

| Pendant Shape: | No |

| Suitable for: | Female, Male, Children, Elderly |

| Style: | Elegant |

| Usage: | Decoration, Health |

| Color: | Pure Titanium |

| Customization: |

Available

| Customized Request |

|---|

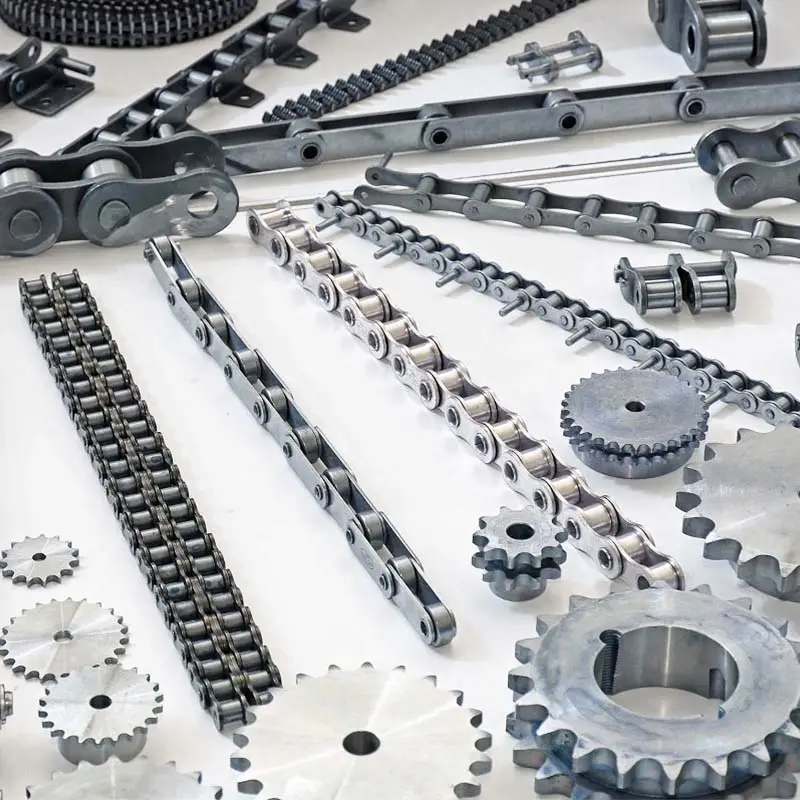

What are the advantages of using a silent chain in an industrial application?

A silent chain, also known as an inverted tooth chain or toothed belt, offers several advantages when used in industrial applications:

1. Quiet operation: Silent chains are designed to minimize noise during operation. The toothed design allows for smooth engagement and disengagement of the chain, resulting in reduced noise levels compared to other chain types. This is particularly beneficial in applications where noise reduction is important, such as in indoor environments or noise-sensitive areas.

2. High load-carrying capacity: Silent chains are capable of carrying heavy loads due to their robust construction. The interlocking toothed design provides excellent power transmission capabilities, allowing for efficient transfer of high torque and load-bearing capacity. This makes silent chains suitable for applications that require heavy-duty performance.

3. Precise positioning and synchronization: Silent chains provide precise positioning and synchronization between the driving and driven components. The toothed profile ensures accurate motion control, making them ideal for applications that require precise timing, such as conveyors, robotics, and automated systems.

4. Low maintenance requirements: Silent chains require minimal maintenance compared to other chain types. The toothed design reduces the need for frequent lubrication, tensioning, and adjustments. This results in lower maintenance costs and less downtime for maintenance activities.

5. High efficiency: Silent chains have high power transmission efficiency due to their positive engagement between the teeth. This means that less energy is wasted during operation, resulting in improved overall system efficiency.

6. Durability and longevity: Silent chains are designed to withstand demanding industrial environments. They are constructed from high-quality materials, such as alloy steel or stainless steel, which provide excellent strength, wear resistance, and corrosion resistance. This ensures a long service life and reduces the need for frequent replacements.

7. Wide range of applications: Silent chains can be used in various industrial applications, including power transmission systems, conveyors, packaging machinery, printing presses, machine tools, and automotive timing systems. Their versatility makes them suitable for a wide range of industries, including manufacturing, automotive, food processing, and pharmaceutical.

Overall, the advantages of using a silent chain in an industrial application include quiet operation, high load-carrying capacity, precise positioning, low maintenance requirements, high efficiency, durability, and versatility. These benefits make silent chains a preferred choice for many industrial applications where reliable and efficient power transmission is required.

How does an industrial chain compare to other types of power transmission systems?

An industrial chain is a type of power transmission system that offers several advantages compared to other systems:

- Strength and durability: Industrial chains are designed to handle heavy loads and withstand tough operating conditions. They are known for their high strength and durability, making them suitable for demanding industrial applications.

- Efficiency: Industrial chains provide efficient power transmission, minimizing energy loss during operation. They offer high mechanical efficiency, which is especially important in applications that require precise and consistent power transfer.

- Flexibility: Industrial chains are flexible in terms of design and configuration. They can be easily adapted to various applications and can transmit power over long distances, making them suitable for a wide range of industrial machinery and equipment.

- Cost-effectiveness: Industrial chains are often cost-effective compared to alternative power transmission systems. They are relatively simple in design, easy to manufacture, and have a lower initial cost. Additionally, their durability and longevity reduce the need for frequent replacements, resulting in long-term cost savings.

- Reliability: Industrial chains are known for their reliability and consistent performance. When properly maintained and operated within their load and speed limits, they can provide reliable power transmission for extended periods.

- Versatility: Industrial chains can accommodate various environmental conditions, including high temperatures, corrosive environments, and high-speed applications. They can be made from different materials and configured with specific features to suit specific application requirements.

While industrial chains offer numerous advantages, it is essential to consider specific application needs and requirements when selecting a power transmission system. Factors such as load capacity, operating environment, speed, and precision may influence the suitability of an industrial chain compared to alternatives such as belts, gears, or shafts.

How do you select the right industrial chain for a specific application?

Selecting the right industrial chain for a specific application involves considering several factors to ensure optimal performance and longevity. Here are the steps to guide you in the selection process:

- Identify the application requirements: Understand the specific needs of your application, such as load capacity, speed, operating environment, and desired functionality.

- Determine the chain type: Based on the application requirements, choose the appropriate chain type, such as roller chains, conveyor chains, leaf chains, or specialty chains.

- Consider chain material: Evaluate the compatibility of the chain material with the operating environment, including factors like corrosion resistance, temperature resistance, and chemical resistance.

- Evaluate chain strength: Determine the required chain strength based on the anticipated loads and forces encountered in the application. Consider factors such as shock loads, tension, and fatigue resistance.

- Calculate chain length: Calculate the required chain length by considering the distance between sprockets, the desired tension, and any adjustments required for installation and maintenance.

- Check for specific features: Determine if any specific features are necessary for the application, such as self-lubricating capabilities, noise reduction, or specialized attachments.

- Consult manufacturer guidelines: Refer to the manufacturer’s guidelines and specifications for the selected chain type to ensure it meets the required standards and specifications.

- Consider maintenance and serviceability: Evaluate the chain’s maintenance requirements and ease of servicing to ensure it can be properly maintained throughout its lifespan.

- Verify compatibility: Confirm the compatibility of the selected industrial chain with the accompanying sprockets, gears, or other components to ensure proper engagement and operation.

- Consider cost-effectiveness: Assess the overall cost-effectiveness of the chain, considering factors such as initial cost, maintenance expenses, and expected lifespan.

By following these steps and considering the specific requirements of your application, you can select the right industrial chain that meets your operational needs and ensures reliable and efficient performance.

editor by CX 2024-04-04

China 14K gold filled necklace 1.37mm O-chain gold filled flat O-shaped necklace jewelry roller chain detacher

Model Quantity: TASPOL57120

Jewelry Main Content: Brass with 14K Gold stuffed

Content Sort: Brass

Gender: Women’s

Principal Stone: None

Jewellery Type: NECKLACES

Necklaces Type: Chains

Occasion: Other, Reward, Marriage, Party

Chain Kind: O-chain

Plating: 1/20 14K GF, 14K Gold filled

Shapepattern: Flat O-chain

Style: O-chain

Inlay technology: none

Substance: Brass with 14K Gold loaded

Colour: Gold

Duration: sixteen inches or 18 inches

width: 1.37mm

MOQ: 2pcs

Packaging Specifics: 1)1pcs/bag. 2) Wrapped in bubble bag. 3) Appropriate luggage in a carton. 4) Or as per customers requests

| item | value |

| Place of Origin | United States |

| Brand Title | DeaiGems |

| Model Variety | TASPOL57120 |

| Jewelry Principal Materials | Brass |

| Material Kind | Brass |

| Jewelry Kind | NECKLACES |

| Necklaces Type | Chains |

| Occasion | Other, Present, Marriage ceremony, Party |

| Chain Sort | O-chain |

| Plating | 1/20 14K GF |

| Shapepattern | flat O-chain |

| Style | O-chain |

| Inlay technology | none |

| Material | Brass with 1/20 14K GF |

| Color | Gold |

| Length | 16 inches or 18 inches |

| width | 1.37mm |

| MOQ | 50pcs |

How to choose a roller chain for a conveyor

When choosing a roller chain for your conveyor, the easiest way is to refer to the horsepower and RPM charts. The horsepower and rpm of the small drive sprocket will determine the size and number of teeth of the chain. Conveyor chains are available in a variety of options, including moving products horizontally, vertically, or around a bend radius. When choosing a conveyor chain, consider the purpose of the chain. For example, if you’re delivering products to customers’ doorsteps, you might choose chains that can move products up and down a hallway or warehouse.

Double pitch

Double pitch roller chains are a popular way to drive agricultural equipment. It has twice the pitch of a standard roller chain and is ideal for light-duty drives. Extended pitch increases performance at lower speeds, but requires fewer components per foot than standard single-pitch chains. Compared to single-pitch roller chains, double-pitch chainplates are longer and are suitable for lighter loads. Read on to learn more about double pitch chains and how they can improve your operation.

The most common type of conveyor chain is double pitch. It is used in the auto parts industry, as well as in the precision machinery industry. It is made from the same components as the standard drive roller chain, except it has longer side plates. Double pitch chains are often used on slow-moving conveyors to reduce the stress placed on them. Industries that commonly use double pitch conveyor chains include airport equipment manufacturers, lumber mills, and fruit packing plants.

RS series roller chains are manufactured from high-quality stainless steel. It has excellent chemical and abrasion resistance and is available in a variety of cord lengths. RS sprockets have over 30 teeth. They contain all the necessary connection links for easy installation. PEER Chain offers double pitch roller chain attachments including pre-stretched chains, sprockets, and other attachments.

Double pitch roller chains have several advantages over standard chains. Double pitch chains have double the pitch, making them ideal for conveying applications such as conveyors. In addition to that, it also provides ANSI-compliant styles. These chains also have free connection links. When shopping for a double pitch roller chain, be sure to choose the one that fits your requirements and budget. They will last longer and save you money in the long run.

Double pitch roller chains to ANSI standards feature oversized rollers. These chains are best suited for applications where the product is mounted on top of the chain. They are ideal for agricultural applications where cotton is on top of the drum. Also, this type of chain is used in light-duty conveyors and agricultural applications. You can find double pitch roller chains in a variety of sizes and styles. And, as long as you know what you want, you’ll be happy with the results.

Self-lubricating

Self-lubricating roller chains eliminate the need for manual relubrication, providing long-lasting operation and reducing maintenance costs. These chains are particularly popular in industries such as the food and beverage industry, textiles, printing, and sawmills. They can also replace standard roller chain drives and conveyor chains. Manufactured to the specific standard ISO R606, these chains are ideal replacements for conventional chains. PC chains are particularly beneficial for food and beverage production and packaging applications due to their anti-corrosion properties.

Self-lubricating roller chains meet ISO, ASME/ANSI, and DIN standards. They are interchangeable with standard chains of the same size and shape and can be used in a variety of industrial applications. Self-lubricating chains have special oil-impregnated sleeves to reduce maintenance time. These chains are also suitable for applications where cleanliness is an issue.

Self-lubricating roller chains are manufactured with unique RS attachments. Rather than a traditional roller chain with an external lubricating ring, this type of chain retains the lubricant within its bushings. During operation, the application generates heat, heating the lubricant, which flows out of the pin and bushing area. Therefore, CZPT roller chains are ideal for certain food conveying applications.

In addition to self-lubricating roller chains, carbon steel, stainless steel or nickel-plated steel are also available. Self-lubricating roller chains are available in different sizes depending on the application, including 0.375″ wide profile straight-chain, extended pin chain, and four-link. In addition, these chains are also available in ANSI and BS chain specifications.

Accumulation

Whether you need to move large or small loads, accumulating roller chains are a viable solution. This chain conveyor is designed with low back pressure to transport large and bulky items with minimal noise. Free-running rollers within the chain help create a smooth build-up surface. These chains are available in a variety of options, including accumulating rollers of different pitches.

The accumulation and release roller chain 14 includes an upper part 15 and a lower part 16. The upper part 15 rests in the upper subspace 28, while the lower part 16 rests on the top side 20 of the profile. As the upper belt 15 rolls around the accumulation roller chain 14, it aligns with the lower chain 16 to form a continuous receiving space. This arrangement allows the accumulation roller chain 14 to rest on the top surface of the support profile 11.

A cumulative roller chain consists of many individual parts. Each section of the chain has an elongated cylindrical shape and is connected to each other by hinged joints. Each chain section also has an accumulation and release roller associated therewith. Each roller protrudes from the upper side 20 and the lower side 21 of the chain portion. The accumulation rollers are movable about an axis 22 extending transversely to the longitudinal axis of the chain.

A feature of the stacking and releasing roller chain is its simplicity. The conveyor has a profiled section that is permanently divided into two cross-sectional spaces. The bottom space is closed from all sides. The upper space accommodates the conveyor line. The contoured portion includes an opening that guides the bottom strap. A shunt can also be inserted between the two sections. The accumulating roller chain system is a convenient and versatile way to move bulky items.

There are many different types of accumulating roller chains. Some chains have offset rollers for optimal load distribution. Others have protection to prevent machine wear. Some run without lubricant, which is a safety advantage. In addition to protection, cumulative chains can also provide protection. The side bow version of the accumulation and release roller chain with offset accumulation and release rollers is designed for conveyor systems with very small bend radii.

Without bushing

Bushless roller chains are the most common type of industrial chain. They are simple in design and require only regular maintenance. Regular maintenance includes lubricating, assessing wear, and replacing worn sprockets. For more information, please read the following information:

The outer chainplates and the inner chain plates are alternately arranged in pairs. The connecting pin extends through the hole in the inner link plate. The rollers thus positioned can be rotated on the connecting pins. Oil provided between the outer circumferential surfaces of each connecting pin serves to lubricate the chain. This system reduces noise and wears caused by collisions between inner chain plates and sprockets.

Compared to traditional roller chains, bushings roller chains have rollers around the bushing. These rollers are in rolling contact with the sprocket teeth, providing low friction and excellent wear resistance. To ensure smooth operation, bushings roller chains must be greased to prevent rust and keep the chain properly tensioned. Lubricated chains run smoother and last longer.

In a bushingless chain, the inner links are shaped like half bushings and ride on the rollers. The pins go through the outer plate and connect the inner links to the rollers. The outer plates overlap the inner links and open the pins. This system is also known as a heterochain. This type of chain is more common than traditional roller chains. If you are not sure which type of bushingless roller chain to choose, you may need to purchase an additional pair of inner chainplates.

Linerless roller chains may also include chain guides. In a bushingless roller chain, the outer and inner link plates conform to the surfaces of the guide rails. Thus, the large area of contact between the chain and the guide rail is eliminated, the friction loss is reduced, and the power transmission efficiency is improved. These properties make bushless roller chains more efficient and durable than traditional roller chains. It’s also less noisy. If you are looking for a chain with a lower noise level, a bushingless roller chain may be the right choice for you.

editor by Cx 2023-07-04

China factory Thermoplastic Conveyor Flat Top Chains LF820-K400 Table Top Conveyor Chains connecting link roller chain

Product Description

| The main application is for conveying various food products and containers. The 820 is a plastic version of the related. The plastic chains however have a reinforcing middle rib underneath. The link thickness is 4.0 mm (0.16 in.) for the 820-series. The links overlap, so there is no space between the links. Plate mat.:POM/PP; Pin mat.:stainless steel Max.speed: 80m/min lubrication; 50m/min dry Max.length:12m; Color:white/brown; Packing unit:10ft(80links) |

| APPLICATIONS: |

| China CZPT Machinery Co.,Ltd is a special supplier of conveyor system components,including plastic and stainless steel flat top chains, Modular belts, other spare parts, such as UHMWPE wearstrips, side guards, chains guide, bipods, tripods, brackets, clampls.ect. With our years of experence, quality products, excellent services we work with world wide clients from America, Europe, Africa, many counrties of Asia. We keep very good business relation with them, and get trusted from them. Our products application: Packaging and conveying industry Beverage bottling and handling industry Food and meat processing industry Chemical industry Pharmaceuticals industry Automobile industry Electrical and electronics industry Textile industry Light engineering industry |

| Material: | Plastic |

|---|---|

| Structure: | Top Chain |

| Surface Treatment: | Low Friction |

| Chain Size: | Pitch 38.1mm |

| Color: | Brown/White/Others |

| Materials: | POM/PP/PE |

| Samples: |

US$ 6/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is a drive chain?

A drive chain is a wheeled device that transmits power from one gear to another. The drive chain is usually an oval ring around a corner or worm gear. On the other hand, idler pulleys do not transmit power and are not used to move the chain. In some cases, drive chains can be used with idler pulleys to transport objects. This allows the drive chain to recover some power from the second gear.

conveyor chain

There are many types of conveyor chains to choose from. One type is a closed joint chain. It consists of the barrel and connecting rod, made from a single casting and heat-treated for high strength and durability. Conveyor chains typically have low running speeds and are typically made of malleable iron. Another type of chain is the power transmission chain, which is used to transmit mechanical power. They feature efficient lubrication and are stronger than conventional conveyor chains.

Roller chain pitches can range from half an inch to a third of an inch. They are available in steel and nickel-plated steel. They can be used with inline or staggered rollers and can be designed with different pitch levels. They can also have bushings between the chainplates or gaps between the teeth to increase their maximum spacing. When choosing a conveyor chain, remember to properly lubricate bearing surfaces to minimize power absorption, wear, and corrosion. Mineral oils of medium viscosity are suitable for normal operating temperatures. SAE 20W50 is suitable. Manufacturers also offer self-lubricating chains.

Conveyor chains are used in many industries. The automotive industry has traditionally used these chains for bulk transport. Their reliability and low cost make them an excellent choice for a variety of applications. CZPT Chains offers stainless steel and CZPT conveyor chains to meet your unique requirements. If you’re in the market for a new conveyor, don’t forget to shop around. CZPT Chain can help you find the perfect one.

The regular drive version consists of an ASME/ANSI roller chain wrapped around a driven sprocket. It can also be configured for variable rpm. The gear ratio between the two parts determines the reduction or increase in speed. In some cases, solution chains can be used. Roller chains are more efficient. Then, there are solutions for both cases. There are many types of conveyor chains to choose from.

Conveyor chain pitch also plays an important role in performance. The smaller the pitch of the chain, the faster it spins. On the other hand, a smaller pitch will require more teeth on the sprocket, which means more links will be engaged during the movement. This smaller articulation angle also produces smoother motion. It also reduces vibration. Therefore, CZPT Chains can be trusted for a long time.

roller chain

The performance of a drive chain depends on how well it is maintained and lubricated. Careful attention to detail is required when selecting a roller chain, which is one of the most important components in a drive chain. Its proper lubrication and assembly will significantly affect its wear life. Here are some important tips to follow when buying a roller chain:

The size of the drive chain should be selected according to the sprockets used. The large sprocket should have at least 25 teeth, and the small sprocket should have fewer teeth. The pitch of a drive chain is the contact angle between the chain and the sprocket. The smaller the sprocket, the smaller the contact angle of the two parts. Larger sprockets are better, but smaller sprockets must never have fewer teeth.

When purchasing a roller chain, be sure to consider the maximum speed of the small sprocket. This will determine how much lubrication you need. Different lubrication systems have different requirements. Manual lubrication limits how many feet per minute the drive chain can run, while oil bath lubrication can get you up to 1100 ft/min. The only way to maximize drive chain speed is to purchase a pump lubrication system.

Once you have the right length, you can determine if you need a new one. To do this you have to move the axis to measure the length. Once the length is determined, the drive chain should be removed from the sprocket and measured using the ANSI specified measuring load. You should also follow safety guidelines when measuring your chain. If you want to maximize the life of your drive chain, be sure to follow these tips.

Another important consideration is the type of environment you operate in. For applications that need to avoid rubbing steel rails, it is best to use a roller chain that can withstand a clean indoor environment. Although roller chains are generally more durable, they must be stored properly to avoid corrosion. If you care about the environment, consider opting for double chain. Its durability and low maintenance costs will make it a valuable investment in your business.

closed pivot

Closed-end pivot drive chains are used in a variety of applications. They are known for their durability, high strength, and long life. They are available in a variety of grades, including grade 400, grade 600, and grade 800 pivots, which can withstand the high forces required for certain applications. Enclosed pivot chains can be used to lift, pull, convey and transfer heavy loads.

Class 400 closed-end pivot chain features one-piece cast offset link construction. Steel pins connect each link and are prevented from rotating by head stops. This design allows the pin to connect inside the barrel without breaking. This type of chain is the most commonly used and has the highest durability. In addition to being extremely durable, it offers long-lasting performance and smooth operation.

Another closed-end pivot conveyor chain drive is called a power drive chain. These chains consist of barrels and links used to transmit rotation from one shaft to another. The barrels of the closed-end pivot chains are made of steel, which allows them to run easily on the sprockets. Block drive chains are used for low-speed applications, but they can be noisy when the chain is in contact with the sprockets.

The enclosed pivot drive chain has rollers on both ends to minimize wear. These chains are usually made of steel and can be used in areas where high-speed power transmission is required. They are also available in heavy-duty versions. Unlike other types of chains, steel pivot chains are designed for a variety of applications. They are suitable for heavy-duty applications and their open barrel design allows for minimal contact with the pins in the barrel and the root of the sprocket.

Linear chain

CZPT is an important part of linear drive technology. This type of chain is capable of delivering real power in tight spaces. Typically, loads are moved by pulling or pushing. CZPT can perform both types of movements. They can push and pull additional loads. This type of chain can also be wound and stored in the magazine. It is a popular choice for small machine tools and many other uses.

Unlike traditional mechanical chains, CZPT uses a push-pull strategy to move heavy objects. It is a rigid locking design that prevents kinking and allows the chain to transmit force without bending. The CZPT is an excellent choice for moving large loads and is particularly versatile in power transmission. However, CZPT is more expensive than traditional drive chain options.

The service life of a linear chain depends on its design, material type and size. You may want to buy a good quality chain, but it’s not necessary in all cases. While superior quality can extend the life of the chain, it may not be necessary for low-speed drives or very light shock loads. If you’re not dealing with high-velocity shock loads, you probably don’t need features like oil reservoirs or bushing grooves.

The size of the drive sprocket can have a major impact on the overall life of the linear chain. It determines how fast the chain can go and how much horsepower it can produce. An 11-tooth chain will hit about half its rated speed, but only about 30 percent of its rated horsepower. You can extend the life of your linear chain by choosing a drive sprocket with a higher number of teeth. It is best to choose a drive sprocket with a high number of teeth, but make sure the number of teeth is even. This will ensure that your chain wear is evenly distributed.

editor by CX 2023-05-23

China Fashion Accessories 18K Gold Plated Jewelry Necklace Soft Flat Snake Chain for Jewelry Design drives roller chain

Product Description

Fashion Components 18K Gold Plated Jewelry Necklace Comfortable Flat Snake Chain for Jewellery Layout

Solution Description

| Merchandise Title: | Necklace |

| Excess weight: | NA |

| MOQ: | 50PCS |

| Content: | Gold Plated Copper |

| Payment: | T/T, Western Union, PayPal ,Escrow and Trade Assurance/Moneygram |

Customized Provider:

Custom made Service: Step By Step Process

| Shopper Submits |

Preliminary supply |

Types |

| For customization, consumers can first provide drawings, images or sketches of goods (contents incorporate: measurement, materials, amount, sort, and budgetary cost of tailored jewellery) | Our product sales staff will supply you with an approximated quotation primarily based on the appropriate information you give, and will listing your demands in the quotation, which is hassle-free for you to affirm details and communicate with us. | Right after confirming the needs with the client and receiving the deposit, our designers will generate a 3D picture in accordance to the customer’s requirements, so that the consumer can confirm whether the item meets the needs. |

| Die engraving | Create a sample | Make and Ship |

| The buyer establishes that the 3D impression is in line with the wants, and our craftsmen will decide the needed abrasives for the most best effect. | Following the engraving is accomplished, the sample will be forged in accordance to the content necessary by the buyer. Soon after the sample is concluded, the client will validate regardless of whether it satisfies the expectations. | After the consumer decides that the anticipated requirements are achieved, the concluded jewelry will be forged and the solution will be mailed to the customer right after completion. |

Company Profile

ZheJiang CZPT Jewellery Co., Ltd. is a jewellery manufacturer specializing in the creation of laboratory diamonds, moissanite, and S925 jewellery, with a wide selection of goods, substantial high quality, cost-effective prices, and distinctive and fashionable patterns. Our merchandise have been commonly acknowledged and dependable by consumers from all in excess of the globe. Also I have my very own crew of designers and investigation craftsmen to produce new products primarily based on client’s sketches, photographs, concepts and requirements. In line with the company philosophy of “quality very first, track record 1st, and thoughtful provider”, the firm wholeheartedly serves every consumer so that absolutely everyone can buy satisfactory jewelry.

Packaging & Shipping

FAQ

Q: Are you a trade organization or a manufacturer?

-A: We are producer specialised in 925 silver/Brass jewelry. OEM & ODM provider are available.(You are always welcome to visit the manufacturing unit,we will prepare to decide-up you.)

Q.Could you supply personal symbol provider?

A:Of course, customers’ emblem services recognized.

What is your minimum get amount?

– Principal substance: 925 sterling silver (30 Items/Pairs)

– Major content: Brass (sixty Items/Pairs)

Q: How to place get ?

-A: We have numerous designs are with inventory, we feel this is a great solution for jewelry entrepreneurs.

-B: For trade Assurance purchase : related to on-line wholesale get ‘s procedure we also can aid you to generate the purchase .Make sure you enable us get in touch with you.

Q: When the merchandise will be all set for cargo?

-A: Cargo date is about 2-twenty five days right after receipt of payment.(inventory Products can be delivered the subsequent working day)

Q: What will be the packing?

-A: Our standard packing is opp bag and bubble wrap to shield your items by most. Personalized packing is recognized, you should make contact with us for far more information.

Q: This is my first time purchase from your firm , how to arrange the shipping way for me?

-A: We ususally ship jewelry by DHL , FEDEX , UPS ,EMS , they are all protected and quickly (generally just take 3-7 times), you just waitting for your goods at your property or your workplace is okay .Following offering merchandise, we will send you monitoring quantity in time.

|

US $1.5-2.5 / Piece | |

2 Pieces (Min. Order) |

###

| Material: | Copper |

|---|---|

| Plating: | Silver, Gold |

| Suitable for: | Female, Male |

| Style: | Fashion |

| Usage: | Decoration |

| Color: | Silver, Gold |

###

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Product Name: | Necklace |

| Weight: | NA |

| MOQ: | 50PCS |

| Material: | Gold Plated Copper |

| Payment: | T/T, Western Union, PayPal ,Escrow and Trade Assurance/Moneygram |

###

| Client Submits |

Initial offer |

Designs |

| For customization, customers can first provide drawings, pictures or sketches of products (contents include: size, material, quantity, type, and budgetary cost of customized jewelry) | Our sales staff will provide you with an estimated quotation based on the relevant information you provide, and will list your requirements in the quotation, which is convenient for you to confirm details and communicate with us. | After confirming the requirements with the customer and receiving the deposit, our designers will create a 3D image according to the customer’s needs, so that the customer can confirm whether the product meets the needs. |

| Die engraving | Build a sample | Make and Ship |

| The customer determines that the 3D image is in line with the needs, and our craftsmen will determine the required abrasives for the most perfect effect. | After the engraving is completed, the sample will be cast according to the material required by the customer. After the sample is completed, the customer will confirm whether it meets the expectations. | Once the client determines that the expected requirements are met, the finished jewelry will be cast and the product will be mailed to the client after completion. |

|

US $1.5-2.5 / Piece | |

2 Pieces (Min. Order) |

###

| Material: | Copper |

|---|---|

| Plating: | Silver, Gold |

| Suitable for: | Female, Male |

| Style: | Fashion |

| Usage: | Decoration |

| Color: | Silver, Gold |

###

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Product Name: | Necklace |

| Weight: | NA |

| MOQ: | 50PCS |

| Material: | Gold Plated Copper |

| Payment: | T/T, Western Union, PayPal ,Escrow and Trade Assurance/Moneygram |

###

| Client Submits |

Initial offer |

Designs |

| For customization, customers can first provide drawings, pictures or sketches of products (contents include: size, material, quantity, type, and budgetary cost of customized jewelry) | Our sales staff will provide you with an estimated quotation based on the relevant information you provide, and will list your requirements in the quotation, which is convenient for you to confirm details and communicate with us. | After confirming the requirements with the customer and receiving the deposit, our designers will create a 3D image according to the customer’s needs, so that the customer can confirm whether the product meets the needs. |

| Die engraving | Build a sample | Make and Ship |

| The customer determines that the 3D image is in line with the needs, and our craftsmen will determine the required abrasives for the most perfect effect. | After the engraving is completed, the sample will be cast according to the material required by the customer. After the sample is completed, the customer will confirm whether it meets the expectations. | Once the client determines that the expected requirements are met, the finished jewelry will be cast and the product will be mailed to the client after completion. |

What is a drive chain?

A drive chain is a wheeled device that transmits power from one gear to another. The drive chain is usually an oval ring around a corner or worm gear. On the other hand, idler pulleys do not transmit power and are not used to move the chain. In some cases, drive chains can be used with idler pulleys to transport objects. This allows the drive chain to recover some power from the second gear.

conveyor chain

There are many types of conveyor chains to choose from. One type is a closed joint chain. It consists of the barrel and connecting rod, made from a single casting and heat-treated for high strength and durability. Conveyor chains typically have low running speeds and are typically made of malleable iron. Another type of chain is the power transmission chain, which is used to transmit mechanical power. They feature efficient lubrication and are stronger than conventional conveyor chains.

Roller chain pitches can range from half an inch to a third of an inch. They are available in steel and nickel-plated steel. They can be used with inline or staggered rollers and can be designed with different pitch levels. They can also have bushings between the chainplates or gaps between the teeth to increase their maximum spacing. When choosing a conveyor chain, remember to properly lubricate bearing surfaces to minimize power absorption, wear, and corrosion. Mineral oils of medium viscosity are suitable for normal operating temperatures. SAE 20W50 is suitable. Manufacturers also offer self-lubricating chains.

Conveyor chains are used in many industries. The automotive industry has traditionally used these chains for bulk transport. Their reliability and low cost make them an excellent choice for a variety of applications. CZPT Chains offers stainless steel and CZPT conveyor chains to meet your unique requirements. If you’re in the market for a new conveyor, don’t forget to shop around. CZPT Chain can help you find the perfect one.

The regular drive version consists of an ASME/ANSI roller chain wrapped around a driven sprocket. It can also be configured for variable rpm. The gear ratio between the two parts determines the reduction or increase in speed. In some cases, solution chains can be used. Roller chains are more efficient. Then, there are solutions for both cases. There are many types of conveyor chains to choose from.

Conveyor chain pitch also plays an important role in performance. The smaller the pitch of the chain, the faster it spins. On the other hand, a smaller pitch will require more teeth on the sprocket, which means more links will be engaged during the movement. This smaller articulation angle also produces smoother motion. It also reduces vibration. Therefore, CZPT Chains can be trusted for a long time.

roller chain

The performance of a drive chain depends on how well it is maintained and lubricated. Careful attention to detail is required when selecting a roller chain, which is one of the most important components in a drive chain. Its proper lubrication and assembly will significantly affect its wear life. Here are some important tips to follow when buying a roller chain:

The size of the drive chain should be selected according to the sprockets used. The large sprocket should have at least 25 teeth, and the small sprocket should have fewer teeth. The pitch of a drive chain is the contact angle between the chain and the sprocket. The smaller the sprocket, the smaller the contact angle of the two parts. Larger sprockets are better, but smaller sprockets must never have fewer teeth.

When purchasing a roller chain, be sure to consider the maximum speed of the small sprocket. This will determine how much lubrication you need. Different lubrication systems have different requirements. Manual lubrication limits how many feet per minute the drive chain can run, while oil bath lubrication can get you up to 1100 ft/min. The only way to maximize drive chain speed is to purchase a pump lubrication system.

Once you have the right length, you can determine if you need a new one. To do this you have to move the axis to measure the length. Once the length is determined, the drive chain should be removed from the sprocket and measured using the ANSI specified measuring load. You should also follow safety guidelines when measuring your chain. If you want to maximize the life of your drive chain, be sure to follow these tips.

Another important consideration is the type of environment you operate in. For applications that need to avoid rubbing steel rails, it is best to use a roller chain that can withstand a clean indoor environment. Although roller chains are generally more durable, they must be stored properly to avoid corrosion. If you care about the environment, consider opting for double chain. Its durability and low maintenance costs will make it a valuable investment in your business.

closed pivot

Closed-end pivot drive chains are used in a variety of applications. They are known for their durability, high strength, and long life. They are available in a variety of grades, including grade 400, grade 600, and grade 800 pivots, which can withstand the high forces required for certain applications. Enclosed pivot chains can be used to lift, pull, convey and transfer heavy loads.

Class 400 closed-end pivot chain features one-piece cast offset link construction. Steel pins connect each link and are prevented from rotating by head stops. This design allows the pin to connect inside the barrel without breaking. This type of chain is the most commonly used and has the highest durability. In addition to being extremely durable, it offers long-lasting performance and smooth operation.

Another closed-end pivot conveyor chain drive is called a power drive chain. These chains consist of barrels and links used to transmit rotation from one shaft to another. The barrels of the closed-end pivot chains are made of steel, which allows them to run easily on the sprockets. Block drive chains are used for low-speed applications, but they can be noisy when the chain is in contact with the sprockets.

The enclosed pivot drive chain has rollers on both ends to minimize wear. These chains are usually made of steel and can be used in areas where high-speed power transmission is required. They are also available in heavy-duty versions. Unlike other types of chains, steel pivot chains are designed for a variety of applications. They are suitable for heavy-duty applications and their open barrel design allows for minimal contact with the pins in the barrel and the root of the sprocket.

Linear chain

CZPT is an important part of linear drive technology. This type of chain is capable of delivering real power in tight spaces. Typically, loads are moved by pulling or pushing. CZPT can perform both types of movements. They can push and pull additional loads. This type of chain can also be wound and stored in the magazine. It is a popular choice for small machine tools and many other uses.

Unlike traditional mechanical chains, CZPT uses a push-pull strategy to move heavy objects. It is a rigid locking design that prevents kinking and allows the chain to transmit force without bending. The CZPT is an excellent choice for moving large loads and is particularly versatile in power transmission. However, CZPT is more expensive than traditional drive chain options.

The service life of a linear chain depends on its design, material type and size. You may want to buy a good quality chain, but it’s not necessary in all cases. While superior quality can extend the life of the chain, it may not be necessary for low-speed drives or very light shock loads. If you’re not dealing with high-velocity shock loads, you probably don’t need features like oil reservoirs or bushing grooves.

The size of the drive sprocket can have a major impact on the overall life of the linear chain. It determines how fast the chain can go and how much horsepower it can produce. An 11-tooth chain will hit about half its rated speed, but only about 30 percent of its rated horsepower. You can extend the life of your linear chain by choosing a drive sprocket with a higher number of teeth. It is best to choose a drive sprocket with a high number of teeth, but make sure the number of teeth is even. This will ensure that your chain wear is evenly distributed.

editor by czh 2023-01-24

China Flat Snake Chain with Gold Plated roller chain drive

Item Description

Flat Snake Chain with gold plated

Solution Description

| Name | Flat Snake Chain with gold plated |

|

Material |

925 sterling silver |

|

Stone |

No stone |

|

Plating |

Gold plated /rose gold /white gold plated |

|

Color |

Gold/rose gold/white gold |

|

Payment |

T/T, L/C, Paypal, Western Union |

|

Direct time |

three~5 Days for Easy Sample, fifteen-25 Days for Mass Creation. |

|

MOQ |

100PCS |

|

Setting |

E-co Friendly |

Company Profile

Proven in 1998, CZPT is a trustworthy model/company/wholesaler in substantial-good quality solid gold & sterling silver wonderful jewellery with above 20 years of layout and production expertise.

We style, manufacture, wholesale, and export CZPT jewellery, gold jewellery, high-conclude metallic jewellery, sterling silver jewellery, and beaded jewellery.

We are mainly in OEM and ODM (excellent capability and flexible QTY), developing the jewellery according to the ideas/patterns/drawings.

We insist on generating the highest high quality and biggest value wholesale products to jewellery brand names/wholesalers/merchants. Top quality and services are our core values.

Clients And Packing

FAQ

1. Are you a factory or trading business?

We are a direct jewelry manufacturing unit for more than twenty many years. We welcome your visit or third get together inspection of our factory before get.

2. Do you accept tiny orders?

Positive, you can acquire any amount from our shares even 1 piece buy is also obtainable

three. Could I have any price cut?

Sure. We will give you a excellent price reduction in accordance to your order’s amount Any other queries, welcome to make contact with us! We do our ideal to remedy it for you!!

four. What are your main materials?

Our main supplies are pure gold, 925 sterling silver, brass, stainless steel.

five:How extended the plating color will be stored?

Plated coloration generally keeps 2 many years, Relies upon on the customer’s put on

six:Do you offer you following-product sales warranty support?

Indeed, About fading, crystal fall off, and other quality difficulties, we offer you guarantee support, but you want to pay the transport price.

7: What is actually the delivery strategy?

According to your prerequisite: By expressway, such as DHL, FEDEX, EMS, Aliexpress and so on Right after delivering goods, we will send you monitoring variety in time.

eight: What’s the payment technique?

We support a variety of payment methods(T/T, Western Union, Paypal, Moneygram, Safe payment-Escrow, and so on) 30% deposit just before creation, the equilibrium ahead of shipping.

nine: How to area an get?

For on the internet wholesale buy: pick deal with and amount-click on buy now-create order remarks-click spend now. we will provide products as soon as possible after your payment reach. we also can help you to develop orders. B: For trade Assurance get: similar to on the internet wholesale order’s approach we also can aid you to develop the purchase

|

US $18.6-19.8 / Piece | |

50 Pieces (Min. Order) |

###

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

###

| Purity: | 92.5% |

|---|---|

| Type: | Necklace |

| Accessory Material: | 925 Sterling Silver |

###

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Name | Flat Snake Chain with gold plated |

|

Material

|

925 sterling silver

|

|

Stone

|

No stone

|

|

Plating

|

Gold plated /rose gold /white gold plated

|

|

Color

|

Gold/rose gold/white gold

|

|

Payment

|

T/T, L/C, Paypal, Western Union

|

|

Lead time

|

3~5 Days for Simple Sample, 15-25 Days for Mass Production.

|

|

MOQ

|

100PCS

|

|

Environment

|

E-co Friendly

|

|

US $18.6-19.8 / Piece | |

50 Pieces (Min. Order) |

###

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

###

| Purity: | 92.5% |

|---|---|

| Type: | Necklace |

| Accessory Material: | 925 Sterling Silver |

###

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Name | Flat Snake Chain with gold plated |

|

Material

|

925 sterling silver

|

|

Stone

|

No stone

|

|

Plating

|

Gold plated /rose gold /white gold plated

|

|

Color

|

Gold/rose gold/white gold

|

|

Payment

|

T/T, L/C, Paypal, Western Union

|

|

Lead time

|

3~5 Days for Simple Sample, 15-25 Days for Mass Production.

|

|

MOQ

|

100PCS

|

|

Environment

|

E-co Friendly

|

Choosing a drive chain for a belt conveyor

The drive chain is used to move heavy objects on the conveyor chain. Chains are magnetic, antistatic, high temperature, or chemical resistant, depending on the application. These types of drive chains are used in many different industries. A common machine that uses this type of drive is a chain hoist. Chain hoists are designed to lift heavy loads with minimal effort. Chains are often used to transport heavy loads.

roller chain

Whether using a roller chain as a drive chain or a belt conveyor can be tricky. Whether it’s a small low-speed drive with manual lubrication or a high-speed pump-lubricated drive with multiple sprockets, there are several factors to consider when choosing a roller chain. First, you need to consider motor horsepower and rpm. The speed of the motor determines how much chain you need. For example, if you are using a low-speed drive, you will need to choose a low-pitch, high-pitch chain. Another thing to consider is chain length – ideally, you can go for an even number of sprockets and chains, but never go smaller.

The lubrication system is also important because the lubrication system must be able to deliver enough oil. The type of oil used to lubricate a chain depends on its operating environment, temperature and speed. Wear is caused by pressure on the bearing, angular sliding of the pins, and rotation of the rollers. There are five different types of lubrication methods available, depending on the system used. A high-quality carbon steel chain is a major advantage when operating at high temperatures, as it can withstand higher temperatures.

The materials of construction for roller chains vary by application. Typically, the most common materials are steel and stainless steel, but sometimes alloy steels are used in food processing machinery that may have lubrication problems. Nylon and brass are also sometimes used. Some industries require heavy-duty chains. If you need an extremely heavy chain, you may want to consider a heavy-duty roller chain. If you are not sure which type of chain is best for your application, consult an industry expert.

Unlike other chains, roller chains are more efficient from a size and weight perspective. While solution chains are useful in some situations, drive chains are more effective for dirty work and slipping on tracks. They are commonly used in construction and manufacturing. There are other advantages to using a drive chain. They are generally stronger than belts, which is a huge benefit. So, if you’re wondering which is better, here are them:

Multi-strand roller chain

The multi-strand roller chains for drive chains market is expected to grow at a CAGR of over 20% during the forecast period. Market reports cover product demand, supply, and cost. The report covers the global market including company profiles, product details, and contact information of key players. It also takes into account the revenue generated by different application areas. The report contains 159 pages of useful information and data. It is an essential tool for anyone involved in drive chain manufacturing.

The essential characteristics of multi-strand chains are their power ratings and allowable bearing area pressures. Power rating is an important characteristic that determines the chain’s ability to transmit a specific load. Typically, multi-strand chains are rated in the range of 12,000 watts per strand. However, their capabilities are limited by link plate fatigue, roller impact fatigue, and wear between pins and bushings.

Energy Series chains are ideal for high-speed and high shock load applications. The chain is designed to provide reliable power and withstand the rigors of the oil and gas industry. It uses high-strength steel and double-coated rolls. These chains come in different lengths and come in two types: single-strand and multi-strand. It is best to consult a professional to find out which chain best suits your needs.

The global multi-strand roller chains market is expected to grow at a CAGR of over 7% during the forecast period. From 2011 to 2019, the industry is expected to grow by nearly 6%. However, the outlook for this market is not optimistic, with some companies experiencing negative growth over the past year. Nonetheless, slowing global economic growth and tightening COVID-19 regulations are likely to hinder the market growth.

Although requirements vary by application, it must be remembered that the load on a multi-strand roller chain must not be greater than 1/9 or 1/6 of the tensile strength of the chain. If the load exceeds this threshold, the chainplates will fatigue. This is the main reason why roller chains are expensive. However, this is not always the case. Multi-strand roller chains are a great idea if you are looking for an affordable and reliable drive chain.

double chain

If you’re looking for an industrial-grade drive chain, you’ve probably considered a double chain. The chain meshes with the sprockets on either side of the gears. It comes in different styles, each with its own advantages and disadvantages. The CZPT duplex series has twice the power capacity of standard SC duplex chains. This type of chain is usually best for new applications. On the other hand, SC double chain chains are the cheapest but have less weight and power capacity.

Another option is a triple drive chain. This type of drive chain has an additional row of plates and contains three sprockets. Its unique design reduces the weight and impact velocity of the timing chain. It is usually used in automotive applications. It is ideal for low to medium-load timing applications. It is also available in acoustically optimized versions. Three-quarter inch pitch double chain chains are widely used in gasoline engine aids and timing drives.

flat top chain

High friction rubber is usually installed on the top or bottom of a flat top drive chain to improve its high friction surface and prevent interference during side bend conveying. The chain plate can be customized with thin rubber layer or thick elastic polyurethane rubber according to customer requirements. In addition to providing high friction, the flat top chain also provides excellent anti-slip properties for glass bottles.

Premium steel flat top chain with high quality surface finish and excellent wear resistance. They have a high level of noise reduction and can be used in heavy duty conveying applications. These chains are available in a variety of alloys such as stainless steel or aluminum. Some models are designed to be very rugged and last longer. Aluminum and galvanized steel chains are popular choices for these chains.

Flat Top Drive Chain Conveyors are versatile and come in an endless combination of configurations. Drives can be connected end-to-end to form long conveyor lines, while side-curved flat-top chains are versatile enough to handle tandem, serpentine or carousel configurations. Standard and heavy duty models are also available. Flat top chains can be used in many different applications including food, beverages and other commodities.

Standard flat top chains are usually rectangular or L-shaped and designed for use on straight conveyors. In some cases, space constraints may require a U-shaped or rectangular conveyor line. For smoother conveying, side-curved flat-top chains can be used. These chains are paired with regular rectangular chain plates and tall pins for high load capacity. They come in different widths, including multi-strand chains.

editor by czh 2022-11-29

Stainless Steel Necklace Flat Cable Chain with Ball for Fashion Accessories

Stainless Metal Necklace Flat Cable Chain with Ball For style accessories

Solution Feature:

one.High quality surgical 316L stainless metal

2.Non tarnished,non rust,and fade

three.No harm to human entire body

four.Several usages for any jewelry design

5.Minimize any meters as clientele need to have

6.Reduced MOQ one hundred meter for every types combine shade

7.Free of charge sample for our inventory design,customer only want to go over transport freight

eight.New types will come out every single month to meet up with your assortment need

9.We may make end chain: reduce the size you want,insert ring,clasper,lobster etc.

ten.Frequent use in several industries: CZPT design and style/Style decoration/CZPT/Promotion/Get together/Purse

Specification:

| Product Identify | Stainless Steel Necklace Flat Cable Chain with Ball For vogue equipment |

| Benefit | Eco-Helpful (Nickel Free, Direct Free of charge),Not rust,Not fade,Not tarnish |

| A lot more than thousand kinds of chain for consumer decision | |

| With a lot more than eight many years complete encounters | |

| Material | 316L steel,surgical quality steel |

| Width | .twenty five/.35/.5mm |

| Size | Minimize meters as buyer want |

| Colors | Metal silver/gold/rose gold/black etc. |

| Gender | girls |

| Electroplating | Assistance 14K/18K gold plated |

| MOQ | a hundred meter for every types,assist combine colors |

| Sample | About 10 varieties of free of charge sample for CZPT inventory,shopper bear shipping freight only |

| Clasp | support add ring,clasp and so on modest components with added value. |

| Implement for | CZPT layout/Handcraft Diy/Bag components/CZPT/Advertising/Decoration and so on. |

| Suitable business | CZPT wholesaler, Distributor, CZPT maker, Fashion Costume firm, Souvenir maker, CZPT maker, and many others. |

| Service | Stock CZPT, OEM&CZPT style manufacture |

| Package deal | Bulk bundle/Opp bag/Jewlery box/CZPTized bundle |

| Shipping time | Sample for completely ready stock,about one-two doing work times |

| Sample not in stock,about 3-4 working days | |

| Massive order for widespread varieties,about one 7 days | |

| Huge purchase for OEM get,about 1-2 weeks,exact time base on purchase amount | |

| Payment way | On the internet payment,Financial institution Transfer |

| Shipping and delivery way | UPS,DHL,FEDEX,TNT,EMS,skilled lineAs asked for |

Item Display:

Package:

Manufacturing facility Present:

Our edge & support:

one.Content: ‘surgical grade’ 316L metal.

Stainless metal jewelry does not tarnish and oxidize, It not like silver will get black, not like copper jewellery allergy inclined, not like alloy jewellery simply because of guide.And it is surprisingly hypoallergenic.

two.Much more than 8 a long time exporting knowledge to CZPT.

We have cooperated with oversea markets entire world extensive,specially in CZPTpe,United Point out,Australia,Korea,Africa and many others,which enjoy well-acknowledged track record in jewelry chain business.

three.Free of charge samples offered,minimal MOQ order CZPT prior to mass generation.

About 10-twenty types of totally free sample for our prepared stock for your option,cilent will be requested to shell out the transport freight only.

Trial purchase with lower MOQ appropriate, demo purchase amount be deduct after spot mass order.

4.Wholesale value&Far more than 1000’s kinds of solution for option.

Very first hand manufacturing facility assist wholesale enterprise with aggressive value,we have our possess investigation&produce division to style new merchandise each and every seasons,much more than thousands types of jewelry chain for your decision,you may uncover any kinds you want.

five.Expert Sales Crew to provide for you at any time, stringent QC team will handle the good quality strictly.

Our product sales team will be on the internet 24 hrs,and will response to you quick.

QC employees will examining each stage in the course of generation,and the items will be double examining prior to ultimate packing and shipment.

6.Packaging:100 meters for each lot,OPP bag and export carton.CZPTized packing is also welcomed.

7.Delivery time: Usually,1-two operating times for all set stock sample order, 3-5 working days for mass production. It depends on the designs and amount.

eight.Payment Phrases: T/T, Lender Transfer. Deposit(fifty% of complete sum) at first, and the equilibrium(50% of total quantity) should be paid out just before shipment.

nine. Shipping Varieties: DHL,TNT,UPS, EMS,FedEx etc.

10.Assistance OEM/ODM get: give us your sample or design to assess for you.

Our Market place:

FAQ:

1.Why choose 316L stainless steel?

Our Surgical Stainless Metal Chain is produced from quality 316 steel, also referred to as ‘marine grade’, meaning it is not going to tarnish or rust. It is a darker, shimmering metal best for remarkable appears.

2.Are you a manufacturer?

Of course, we are an skilled company with our personal creation strains.Our Manufacturing unit in Chang’an Xihu (West Lake) Dis. guang and business office in HangCZPT Shuibei CZPT Center.

3.What is the jewelry’s maintenance?

1).Keep away from creating your jewelry get in touch with mordant liquid as far as attainable, this kind of as fragrance, sweat, cleaner, sanitizer, water, shower gel when wearing.

two).To hold the gloss of your jewellery, you would greater to wipe it with DFJC or thoroughly clean and comfortable dry cloth soon after putting on.

3).Put your jewellery in your jewelry circumstance to prevent it from getting in touch with daylight and moist air when you are not putting on jewellery for a long time.

four.Is the marking value on internet site is the final price for buying?

Not exactly,the price selection is only for reference,exact price tag is diverse foundation on merchandise width, length, quantity,hues,market demand etc, so pls make contact with us to get final actual price tag,thanks for comprehending.

China Roller chain and sprocket manufacturer Single flat top chain sunglasses in Lubango Angola Drum Roller Gyrc-60 with Hydraulic Adjustable Control Lever with ce certificate top quality low price

We – EPG Team the most significant Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches.

Our merchandise are made by present day computerized machinery and tools.a specialized provider of a entire selection of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….ISO With EPG brand registered in much more than 70 nations around the world like The usa , Europe , Japan and so on, it has partners amid entire world top enterprises, such as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so on.9001 accredited manufacturer of precision roller chains. Sorts include solitary and a number of strand, hollow pin, side bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains. Our huge inventory levels on zinc plated, sound steel shaft collars guarantee prompt satisfaction of any size need. Unplated, black-oxide and stainless steel strong collars are commonly accessible. Black-oxide metal clamp variety collars are equally stocked for unbeatable service. Mounted bearing and linear bearing orders are regularly transported inside of 24 hours and our change-about time on minimize-to-length linear shafting will exceed your expectations. Substantial Good quality Solitary Drum Roller GYRC-60 With EPT Adjustable Management Lever

Functions&colon

one&rparHonda 4-stroke GX160 Engine&lparor Robin EX17&rpar is effortless to commence&commaassuring high quality and excellent functionality&period

2&rparEasy get to contro EPT for operator ease and comfort

three&rparErgonomically designed top-adjustable handle adopts airplane gear system&commaprovides highest ease and comfort and easy transportation for operators of distinct heights

4&rparSelf-cleansing scrapers prevent the develop-up of dust

5&rparBeveled drum edge removes markings on surface area

six&rparSide and suppress clearance let for a closet strategy to pavement&comma wall&comma suppress and EPT impediment

7&rparCompact layout for easy handling in confined locations

eight&rparThick drum shel EPT for more time drum life

9&rparLarge corrosion-cost-free water tank tends to make it feasible for filling&commadisassembly and cleaning without tool

ten&rparFully hydraulic technique provides infinitely variable operating speed for journey and vibration&comma reducing the want for standard periodic adjustments and modifications in comparison to chain driven rollers demand&time period

eleven&rparBuilt-in cooling supporter is designed for lengthier existence and continuous operation

twelve&rparThe sprayed surface is gorgeous&commarust-proof and corrosion resistant&period

Specification&colon

| Model | GYRC-60 |

| Engine Variety | Honda GX160 |

| Electrical power kw&lparhp&rpar | four&period0&lpar5&period5&rpar |

| Fat kg&lparlbs&rpar | three hundred&lpar660&rpar |

| Drum Diameter cm&lparin&rpar | sixty&ast38&lpar23&ast15&rpar |

| Centrifugal Drive kN | fifteen |

| Frequency vpm&solhz | 4100&lpar70&rpar |

| Journey Velocity km&solhr | 2&period5 |

| Drinking water tank Capability L | twenty five |

The use of original tools manufacturer’s (OEM) part figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our company and the shown substitute parts contained herein are not sponsored, accepted, or created by the OEM.