Product Description

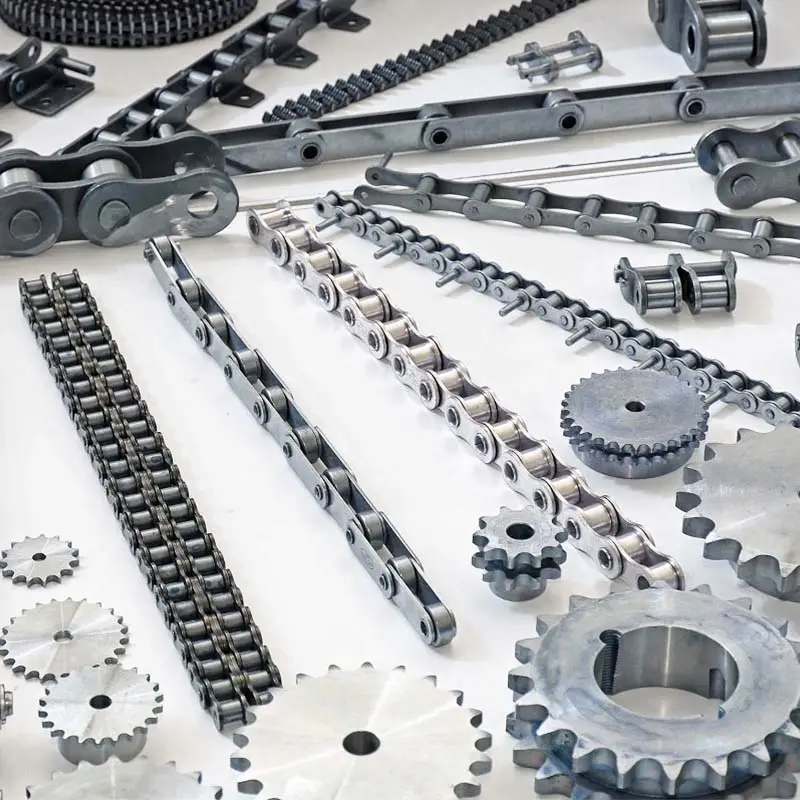

Precision industrial chain 20A-4 row chain single row double row carbon steel roller chain

Product introduction

| Material | Carbon steel, alloy steel |

| Surface Treatment | Polishing,Original Colour,Polishing |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery ……… |

| Standard or Nonstandard | Standard |

| Heat Treatment: | High Temperature Hardening |

| Color | Elf,dark yellow,dark blue,black |

| Features |

•Large reduction ratio (usually up to 1:7) |

HIGH STHangZhouRD HEAT TREATMENT

Through high standards,strictly control the heat,improve the hardness/strength and provide service life.

HIGH QUALITY MATERIAL

Beautiful and corrosion-resistant, the product surface is treated with rust prevention, beautiful and simple!

STHangZhouRD THICKNESS CHAIN PIECE

The thickness is customized from raw material chain plate in strict accordance with the standard

STHangZhouRD CHINAMFG PIN

Cutting in strict accordance with the standard, second screening,

and never cut corners

Green Power Industry Co Llimited is an international export enterprise combined with factory specializing in the manufacturing of brake system , clutch system,spark plug and chain . Our company is a professional manufacturer and supplier of brake,chain and clutch in China. We both have our own brake CHINAMFG factory, brake pad factory, brake shoe factory ,clutch disc factory,chain factory, spark plug factory .We focus on developing high-quality products for OEM market ,Our company have developed and produced high quality brake in formula non -metallic and asbestos free for automobile and brake shoe assembly for heavy duty truck . The production are noted good characteristics such as high strength , high heat-resisting , wear-resisting.low dust virtue ,no noise and better stability . The series products had been exporting to North -America ,Europe ,Middle -East ,Australia and etc, widely sale to domestic OEM factories and aftermarket.

Our company is composed of professional team , process advanced production inspection and testing equipment Each product have passed the first inspection, process inspection, error prevention, and laboratory tests to ensure that each piece of qualified products sent to customers

We are determined to set up the aim of “excellent quality and satisfying service·, with·the first class quality , reasonable price and perfect service . we set strick demand and operate conforming to the standard to guarantee all the products can be meet our customer’s needs

1.Q: What is the certificate of your factory?

A: We have passed IAF ISO and TS16949 certification.

2.Q: Can it be produced according to the sample?

A: Yes, we can produce through your samples or technical drawings. We can build molds and fixtures.

3.Q: Do you test all products before shipping?

A: Yes, we conduct 100% quality testing before delivery, and we are 100% responsible for product quality.

4.Q: What is your delivery time?

A:If we have stock, we can send it immediately within a week. If not, it usually ranges from 7 days to 35 days, depending on the quantity.

5.Q: What is your sample policy?

A: We want to provide you with samples for approval. There will be no charge for 1 or 2 samples, but the customer needs to bear the courier fee first.

It will be drawback to customer when order placed

6.Q: How do you make our business establish a long-term good cooperative relationship?

A:1. We maintain excellent quality and competitive prices to ensure that our customers benefit;

2. We respect every customer as our friend, we do business sincerely and make friends widely,No matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain, Conveyor Chain |

|---|---|

| Material: | Carbon steel, alloy steel |

| Surface Treatment: | Polishing |

| Feature: | Heat Resistant |

| Chain Size: | 1/2"*3/32" |

| Structure: | Roller Chain |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you troubleshoot chain skipping or slipping issues in an industrial chain?

Chain skipping or slipping issues in an industrial chain can lead to decreased efficiency and potential equipment damage. Here are some steps to troubleshoot and address these issues:

- Check chain tension: Ensure that the chain is properly tensioned according to the manufacturer’s recommendations. An overly loose or tight chain can cause skipping or slipping.

- Inspect sprockets: Examine the sprockets for signs of wear, damage, or misalignment. Worn or damaged sprocket teeth can cause chain skipping. Correct any alignment issues and replace worn sprockets if necessary.

- Inspect chain condition: Inspect the chain for signs of wear, elongation, or damage. A worn or stretched chain may not properly engage with the sprockets, leading to skipping or slipping. If the chain is significantly worn, it may need to be replaced.

- Clean and lubricate the chain: Clean the chain thoroughly to remove any debris or contaminants that may be affecting its performance. Apply a suitable lubricant to ensure smooth operation and reduce friction.

- Check drive system components: Examine other components of the drive system, such as bearings, shafts, and gears, for any signs of damage or misalignment. These components can also contribute to chain skipping or slipping.

- Adjust alignment: Ensure that the entire chain drive system is properly aligned. Misalignment can cause uneven tension distribution and lead to chain skipping. Adjust the alignment as needed.

- Inspect drive system tensioners: If the chain drive system includes tensioners, check their condition and adjustment. A malfunctioning or improperly adjusted tensioner can contribute to chain skipping.

- Consult manufacturer guidelines: Refer to the manufacturer’s guidelines and specifications for the specific industrial chain and equipment being used. Follow their recommended troubleshooting steps and maintenance practices.

- Seek professional assistance if needed: If the issue persists or if you are unsure about the troubleshooting process, it is recommended to seek assistance from a qualified technician or the manufacturer’s technical support team.

Addressing chain skipping or slipping issues promptly is important to prevent further damage and maintain the efficiency and reliability of the industrial chain system.

How do you optimize the efficiency of an industrial chain system?

Optimizing the efficiency of an industrial chain system involves various factors and considerations. Here are some key steps to achieve maximum efficiency:

1. Proper Design: Ensure that the industrial chain system is designed correctly for the specific application. Consider factors such as load capacity, speed, environment, and required service life when selecting the chain and related components.

2. Adequate Lubrication: Proper lubrication is essential for reducing friction, wear, and energy loss in the chain system. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant type and quantity.

3. Correct Tensioning: Maintaining the right tension in the chain is crucial for optimal performance. Over-tensioning or under-tensioning can lead to increased wear, power loss, and premature failure. Regularly check and adjust the tension as per the manufacturer’s guidelines.

4. Alignment and Sprocket Inspection: Ensure proper alignment of the chain and sprockets. Misalignment can cause excessive wear and energy loss. Regularly inspect the sprockets for signs of wear, damage, or misalignment, and replace or adjust as necessary.

5. Minimize Friction and Resistance: Reduce friction and resistance throughout the chain system by keeping the components clean and free from debris. Regularly clean and inspect the chain, sprockets, and guides to remove any accumulated dirt or contaminants.

6. Maintenance and Inspection: Implement a regular maintenance and inspection schedule for the entire chain system. This includes checking for wear, lubrication status, tension, and alignment. Address any issues promptly to prevent further damage and ensure optimal performance.

7. Training and Education: Provide proper training to operators and maintenance personnel on the correct handling, operation, and maintenance of the industrial chain system. This will help ensure that everyone understands the importance of efficiency and follows best practices.

By following these optimization strategies, the efficiency of an industrial chain system can be improved, leading to reduced energy consumption, extended service life, and cost savings in the long run.

What are the signs of wear and tear in an industrial chain?

Monitoring the condition of an industrial chain is essential to identify signs of wear and tear. Here are some common signs to watch for:

- Chain Elongation: Measure the chain’s pitch to check for elongation. Excessive elongation indicates wear in the chain and can lead to poor performance and premature failure.

- Worn Sprocket Teeth: Inspect the sprocket teeth for signs of wear. Worn or misshapen teeth can cause the chain to skip or slip, resulting in decreased efficiency and increased stress on the system.

- Chain Flexibility: Assess the flexibility of the chain by bending it. If the chain is stiff or has tight spots, it may indicate corrosion, inadequate lubrication, or worn components.

- Visible Damage: Look for any visible damage on the chain, such as bent links, cracked or broken plates, or missing pins or rollers. These can weaken the chain’s integrity and compromise its performance.

- Excessive Noise: Unusual noise during operation, such as grinding, rattling, or squeaking, can indicate a problem with the chain. It may be caused by misalignment, inadequate lubrication, or worn components.

- Increased Friction: Check for excessive heat or signs of friction, such as discoloration or hot spots. Increased friction can accelerate wear and lead to premature failure.

- Poor Tension: Assess the chain’s tension by checking for slack or excessive tightness. Improper tension can cause the chain to wear unevenly and affect its performance.

Regular inspections and maintenance are crucial to identify these signs of wear and tear. Addressing issues promptly, such as replacing worn components or adjusting tension, can help prolong the life of the industrial chain and prevent unexpected failures.

editor by CX 2024-05-06

China Good quality Attachment Roller Chain Industrial Single Strand Steel Conveyor Chain

Product Description

OUR PRODUCTS LIST:

A and B series single/double/triple standard roller chain and no-standard roller chain

| DIN/ISO | ANSI | Pitch | Roller | Width | Pin | Pin | Lnner | Plate | Ultimate | Average | weight | |

| KIN/ISO | ANSL | between | diameter | length | plate | thick | tensile | tensile | per | |||

| Chain | Chain | inner plates | depth | -ness | strength | strength | meter | |||||

| No. | No. | P | d1 | b1 | d2 | L | Lc | h2 | T | Q | Q0 | q |

| max | min | max | max | max | max | max | min | |||||

| mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kN | kg/m | ||

| *03C | *15 | 4.7625 | 2.48 | 2.38 | 1.62 | 6.1 | 6.9 | 4.3 | 0.6 | 1.80/409 | 2 | 0.08 |

| *04C-1 | *25 | 6.35 | 3.3 | 3.18 | 2.31 | 7.9 | 8.4 | 6 | 0.8 | 3.50/795 | 4.6 | 0.15 |

| *06C-1 | *35 | 9.525 | 5.08 | 4.77 | 3.58 | 12.4 | 13.17 | 9 | 1.3 | 7.90/1795 | 10.8 | 0.33 |

| 085-1 | 41 | 12.7 | 7.77 | 6.25 | 3.58 | 13.75 | 15 | 9.91 | 1.3 | 6.67/1516 | 12.6 | 0.41 |

| 08A-1 | 40 | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 17.8 | 12 | 1.5 | 14.10/3205 | 17.5 | 0.62 |

| 10A-1 | 50 | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 22.2 | 15.09 | 2.03 | 22.20/5045 | 29.4 | 1.02 |

| 12A-1 | 60 | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18 | 2.42 | 31.80/7227 | 41.5 | 1.5 |

| 16A-1 | 80 | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 35 | 24 | 3.25 | 59.70/12886 | 69.4 | 2.6 |

| 20A-1 | 100 | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 88.50/20114 | 109.2 | 3.91 |

| 24A-1 | 120 | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 127.00/28864 | 156.3 | 5.62 |

| 28A-1 | 140 | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 172.40/39182 | 212 | 7.5 |

| 32A-1 | 160 | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 226.80/51545 | 278.9 | 1.1 |

| 36A-1 | 180 | 57.15 | 35.71 | 35.48 | 17.46 | 72.8 | 78.6 | 53.6 | 7.2 | 280.20/63682 | 341.8 | 13.45 |

| 40A-1 | 200 | 63.5 | 39.68 | 37.85 | 19.85 | 80.3 | 87.2 | 60 | 8 | 353.80/80409 | 431.6 | 16.15 |

| 48A-1 | 240 | 76.2 | 47.63 | 47.35 | 23.81 | 90.5 | 103 | 72.39 | 9.5 | 51.30/115977 | 622.5 | 23.2 |

| DIN/ISO | Pitch | Roller | Width | Pin | Pin | Lnner | Plate | Ultimate | Average | weight | |

| KIN/ISO | between | diameter | length | plate | thick | tensile | tensile | per | |||

| Chain | inner plates | depth | -ness | strength | strength | meter | |||||

| No. | P | d1 | b1 | d2 | L | Lc | h2 | T | Q | Q0 | q |

| max | min | max | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kN | kg/m | |

| 04B-1 | 6 | 4 | 2.8 | 1.85 | 6.8 | 7.8 | 5 | 0.6 | 3.2/682 | 3.2 | 0.11 |

| 05B-1 | 8 | 5 | 3 | 2.31 | 8.2 | 8.9 | 7.1 | 0.8 | 5.0/1136 | 5.9 | 0.2 |

| *06B-1 | 9.525 | 6.35 | 5.72 | 3.28 | 13.15 | 14.1 | 8.2 | 1.3 | 9.0/2045 | 10.4 | 0.41 |

| 08B-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.7 | 18.2 | 11.8 | 1.6 | 18.0/4091 | 19.4 | 0.69 |

| 10B-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.5 | 20.9 | 14.7 | 1.7 | 22.4/5091 | 27.5 | 0.93 |

| 12B-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22.5 | 24.2 | 16 | 1.85 | 29.0/6591 | 32.2 | 1.15 |

| 16B-1 | 25.4 | 15.88 | 17.02 | 8.28 | 36.1 | 37.4 | 21 | 4.15/3.1 | 60.0/13636 | 72.8 | 2.71 |

| 20B-1 | 31.75 | 19.05 | 19.56 | 10.19 | 41.3 | 45 | 26.4 | 4.5/3.5 | 95.0/21591 | 106.7 | 3.7 |

| 24B-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 57.8 | 33.2 | 6.0/4.8 | 160.0/36364 | 178 | 7.1 |

| 28B-1 | 44.45 | 27.94 | 30.99 | 15.9 | 65.1 | 69.5 | 36.7 | 7.5/6.0 | 200.0/45455 | 222 | 8.5 |

| 32B-1 | 50.8 | 29.21 | 30.99 | 17.81 | 66 | 71 | 42 | 7.0/6.0 | 250.0/56818 | 277.5 | 10.25 |

| 40B-1 | 63.5 | 39.37 | 38.1 | 22.89 | 82.2 | 89.2 | 52.96 | 8.5/8.0 | 355.0/80682 | 394 | 16.35 |

| 48B-1 | 76.2 | 48.26 | 45.72 | 29.24 | 99.1 | 107 | 63.8 | 560.0/127272 | 621.6 | 25 | |

Products show

Our workshop

Our hot treatment equipment

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in single color box. If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance. Other payments terms, pls negotiate with us in advance, we can discuss.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.We welcome sample order.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

| Material: | Alloy |

|---|---|

| Structure: | Combined Chain |

| Surface Treatment: | Electroplating |

| Chain Size: | 1/2"*3/32" |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Transport Package: | Non-Fumigation Wooden Box, by Air, by Ocean |

| Samples: |

US$ 2/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you determine the expected lifespan of an industrial chain?

The expected lifespan of an industrial chain can vary depending on various factors. Here's how you can determine the expected lifespan of an industrial chain:

- Manufacturer’s specifications: Start by referring to the manufacturer’s specifications and guidelines for the industrial chain. Manufacturers often provide information about the estimated lifespan based on the chain’s design, material, and intended use.

- Operating conditions: Evaluate the operating conditions in which the industrial chain will be used. Factors such as temperature, humidity, exposure to chemicals or abrasive materials, and load conditions can significantly impact the chain’s lifespan. Consider whether the chain will be subject to heavy loads, frequent starts and stops, or continuous operation.

- Maintenance practices: Proper maintenance is essential for prolonging the lifespan of an industrial chain. Follow the manufacturer’s recommended maintenance procedures, including regular cleaning, lubrication, and inspection. Neglecting maintenance can lead to premature wear and reduce the chain’s lifespan.

- Chain wear monitoring: Implement a chain wear monitoring program to track the condition of the chain over time. This can involve measuring the elongation of the chain, inspecting for signs of wear, and conducting regular maintenance checks. By monitoring wear, you can anticipate when the chain may need replacement.

- Application-specific factors: Consider any unique factors related to the specific application. This may include factors like shock loads, vibration, misalignment, or exposure to extreme conditions. These factors can accelerate wear and impact the chain’s lifespan.

- Historical data and experience: Drawing from historical data and experience with similar applications can provide insights into the expected lifespan of the industrial chain. If there are past records of chain performance in similar operating conditions, they can serve as a reference point.

It's important to note that determining the exact lifespan of an industrial chain is challenging as it depends on various factors. Regular monitoring, proper maintenance, and adherence to recommended operating conditions can help maximize the chain's lifespan.

How does an industrial chain compare to other types of power transmission systems?

An industrial chain is a type of power transmission system that offers several advantages compared to other systems:

- Strength and durability: Industrial chains are designed to handle heavy loads and withstand tough operating conditions. They are known for their high strength and durability, making them suitable for demanding industrial applications.

- Efficiency: Industrial chains provide efficient power transmission, minimizing energy loss during operation. They offer high mechanical efficiency, which is especially important in applications that require precise and consistent power transfer.

- Flexibility: Industrial chains are flexible in terms of design and configuration. They can be easily adapted to various applications and can transmit power over long distances, making them suitable for a wide range of industrial machinery and equipment.

- Cost-effectiveness: Industrial chains are often cost-effective compared to alternative power transmission systems. They are relatively simple in design, easy to manufacture, and have a lower initial cost. Additionally, their durability and longevity reduce the need for frequent replacements, resulting in long-term cost savings.

- Reliability: Industrial chains are known for their reliability and consistent performance. When properly maintained and operated within their load and speed limits, they can provide reliable power transmission for extended periods.

- Versatility: Industrial chains can accommodate various environmental conditions, including high temperatures, corrosive environments, and high-speed applications. They can be made from different materials and configured with specific features to suit specific application requirements.

While industrial chains offer numerous advantages, it is essential to consider specific application needs and requirements when selecting a power transmission system. Factors such as load capacity, operating environment, speed, and precision may influence the suitability of an industrial chain compared to alternatives such as belts, gears, or shafts.

What are the signs of wear and tear in an industrial chain?

Monitoring the condition of an industrial chain is essential to identify signs of wear and tear. Here are some common signs to watch for:

- Chain Elongation: Measure the chain’s pitch to check for elongation. Excessive elongation indicates wear in the chain and can lead to poor performance and premature failure.

- Worn Sprocket Teeth: Inspect the sprocket teeth for signs of wear. Worn or misshapen teeth can cause the chain to skip or slip, resulting in decreased efficiency and increased stress on the system.

- Chain Flexibility: Assess the flexibility of the chain by bending it. If the chain is stiff or has tight spots, it may indicate corrosion, inadequate lubrication, or worn components.

- Visible Damage: Look for any visible damage on the chain, such as bent links, cracked or broken plates, or missing pins or rollers. These can weaken the chain’s integrity and compromise its performance.

- Excessive Noise: Unusual noise during operation, such as grinding, rattling, or squeaking, can indicate a problem with the chain. It may be caused by misalignment, inadequate lubrication, or worn components.

- Increased Friction: Check for excessive heat or signs of friction, such as discoloration or hot spots. Increased friction can accelerate wear and lead to premature failure.

- Poor Tension: Assess the chain’s tension by checking for slack or excessive tightness. Improper tension can cause the chain to wear unevenly and affect its performance.

Regular inspections and maintenance are crucial to identify these signs of wear and tear. Addressing issues promptly, such as replacing worn components or adjusting tension, can help prolong the life of the industrial chain and prevent unexpected failures.

editor by CX 2023-09-23

China Roller chain and sprocket manufacturer Single flat top chain sunglasses in Lubango Angola Drum Roller Gyrc-60 with Hydraulic Adjustable Control Lever with ce certificate top quality low price

We – EPG Team the most significant Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches.

Our merchandise are made by present day computerized machinery and tools.a specialized provider of a entire selection of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….ISO With EPG brand registered in much more than 70 nations around the world like The usa , Europe , Japan and so on, it has partners amid entire world top enterprises, such as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so on.9001 accredited manufacturer of precision roller chains. Sorts include solitary and a number of strand, hollow pin, side bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains. Our huge inventory levels on zinc plated, sound steel shaft collars guarantee prompt satisfaction of any size need. Unplated, black-oxide and stainless steel strong collars are commonly accessible. Black-oxide metal clamp variety collars are equally stocked for unbeatable service. Mounted bearing and linear bearing orders are regularly transported inside of 24 hours and our change-about time on minimize-to-length linear shafting will exceed your expectations. Substantial Good quality Solitary Drum Roller GYRC-60 With EPT Adjustable Management Lever

Functions&colon

one&rparHonda 4-stroke GX160 Engine&lparor Robin EX17&rpar is effortless to commence&commaassuring high quality and excellent functionality&period

2&rparEasy get to contro EPT for operator ease and comfort

three&rparErgonomically designed top-adjustable handle adopts airplane gear system&commaprovides highest ease and comfort and easy transportation for operators of distinct heights

4&rparSelf-cleansing scrapers prevent the develop-up of dust

5&rparBeveled drum edge removes markings on surface area

six&rparSide and suppress clearance let for a closet strategy to pavement&comma wall&comma suppress and EPT impediment

7&rparCompact layout for easy handling in confined locations

eight&rparThick drum shel EPT for more time drum life

9&rparLarge corrosion-cost-free water tank tends to make it feasible for filling&commadisassembly and cleaning without tool

ten&rparFully hydraulic technique provides infinitely variable operating speed for journey and vibration&comma reducing the want for standard periodic adjustments and modifications in comparison to chain driven rollers demand&time period

eleven&rparBuilt-in cooling supporter is designed for lengthier existence and continuous operation

twelve&rparThe sprayed surface is gorgeous&commarust-proof and corrosion resistant&period

Specification&colon

| Model | GYRC-60 |

| Engine Variety | Honda GX160 |

| Electrical power kw&lparhp&rpar | four&period0&lpar5&period5&rpar |

| Fat kg&lparlbs&rpar | three hundred&lpar660&rpar |

| Drum Diameter cm&lparin&rpar | sixty&ast38&lpar23&ast15&rpar |

| Centrifugal Drive kN | fifteen |

| Frequency vpm&solhz | 4100&lpar70&rpar |

| Journey Velocity km&solhr | 2&period5 |

| Drinking water tank Capability L | twenty five |

The use of original tools manufacturer’s (OEM) part figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our company and the shown substitute parts contained herein are not sponsored, accepted, or created by the OEM.