Product Description

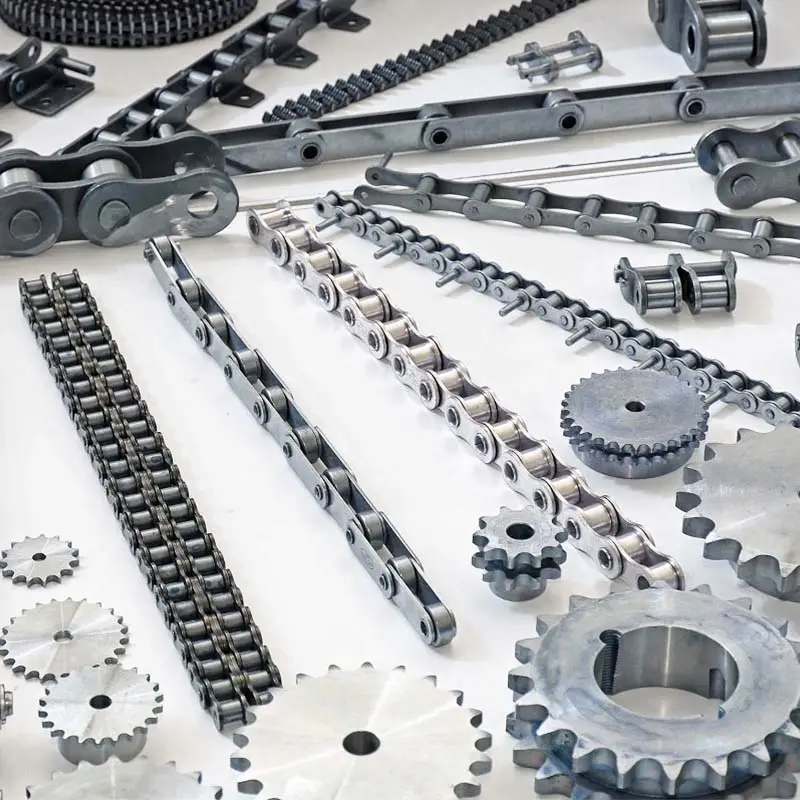

Short Pitch Precision Roller Chains

A. Our Services:

1. Any of your kind inquiry about chain would be replied within 24 hours.

2. Well-trained and experienced sales staffs will reply all your concerns in fluent English.

3. OEM services are available with us, our professional designer would make your private idea into being.

4. Protection of your sales area, ideas of design and all your private information.

5. Delivery by air mail or ship for your orders.

6. With years of manufacture and promotion experience in global market, brings you profit and great success!

B.Product Description:

| Style: | Simplex Roller Chains, Duplex Roller Chains, Triplex Roller Chains, Multiple Roller Chains |

| Chain No.: (ANSI/ISO) | 03C, 04C, 06C, 08A, 10A, 12A-~ 48A |

| Chain No.: ( ANSI ) | 15, 25,35,41,40,50 ~ 240 |

| Pitch: | 4.7625 mm ~ 76.200 mm |

C.Company show & Product Process

D. Packaging & Certificate

| Packaging Details: | Chain+Plastic Bag+Neutral Box+Wooden case+Big Carton+Steel Pallets |

| Delivery Detail: | five weeks |

E. FAQ:

1. Are you manufacturer or trade Company?

We are a factory founded in 1991 with trade team for international service.

2. What terms of payment you usually use?

T/T 30% deposit and 70% against document, Western Union, L/C at sight

3. what is your lead time for your goods?

Normally 45 days after confirmed order. 30 days could be available in low season for some items (during May to July), and 65 days during new year and hot season ( Jan to March).

4. Do you attend any Show?

We attend Hannover show in Germany, NMW in Austrilia, Canton fair, PTC, in China and many other special furniture shows.

5. Do you have any instant chat ?

| Usage: | Conveyor Chain |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Electroplating |

| Feature: | Heat Resistant |

| Chain Size: | 1/2"*11/128" |

| Structure: | Roller Chain |

| Customization: |

Available

| Customized Request |

|---|

Can an industrial chain be used in food processing applications?

Yes, industrial chains can be used in food processing applications, but it’s important to select the right type of chain that meets the specific requirements of the application. Here are some considerations:

- Food-grade materials: When choosing an industrial chain for food processing, it is crucial to ensure that the chain is made of food-grade materials that comply with the necessary food safety standards. Stainless steel or plastic chains are commonly used in food processing due to their corrosion resistance and ease of cleaning.

- Hygienic design: Industrial chains for food processing applications should have a hygienic design that minimizes the accumulation of debris, allows for easy cleaning, and prevents the growth of bacteria. Smooth surfaces, open construction, and self-draining features are desirable.

- Chemical resistance: Food processing environments may involve exposure to various cleaning chemicals and sanitizers. The industrial chain should be resistant to these chemicals to maintain its integrity and avoid contamination.

- Temperature resistance: Depending on the food processing application, the chain may be exposed to high or low temperatures. It’s important to select a chain that can withstand the temperature range required for the specific process.

- Load capacity: Consider the load requirements of the application. Food processing operations may involve heavy loads, so the chain should have the appropriate load capacity to ensure safe and reliable operation.

- Compliance with regulations: Food processing facilities must adhere to strict regulations and standards related to food safety and hygiene. Ensure that the selected industrial chain complies with these regulations to maintain a safe and sanitary environment.

By selecting an industrial chain specifically designed for food processing applications and following proper maintenance and cleaning procedures, the chain can effectively and safely contribute to the food processing operations.

What are the common causes of industrial chain failures?

Industrial chain failures can occur due to various factors:

- Excessive load: Applying a load that exceeds the chain’s capacity can lead to stress and failure. It is important to consider the chain’s rated load and choose the appropriate chain for the application.

- Inadequate lubrication: Insufficient or improper lubrication can result in increased friction and wear, leading to premature chain failure. Regular lubrication with the recommended lubricant and following the manufacturer’s guidelines is crucial.

- Improper tensioning: Incorrect chain tension can cause misalignment, premature wear, and failure. Proper tensioning ensures optimal performance and longevity of the chain.

- Misalignment: Poor alignment between the sprockets can cause the chain to wear unevenly and increase the risk of failure. Proper alignment of the sprockets is essential for smooth operation.

- Wear and tear: Continuous use without proper maintenance and regular inspection can result in chain fatigue, elongation, and eventual failure. Regular inspection and timely replacement of worn-out components are necessary to prevent failure.

- Corrosion: Exposure to corrosive environments can weaken the chain material and compromise its integrity. Using corrosion-resistant chains or applying appropriate coatings can mitigate the risk of corrosion-related failures.

- Lack of maintenance: Neglecting routine maintenance tasks such as cleaning, lubrication, and inspection can lead to chain degradation and eventual failure. Regular maintenance is essential to ensure optimal chain performance and longevity.

What factors should be considered when designing an industrial chain system?

Designing an industrial chain system involves careful consideration of various factors to ensure optimal performance, reliability, and safety. Here are some key factors to consider:

- Load Requirements: Determine the maximum load the chain system will need to handle, including static and dynamic loads. Consider factors such as weight, acceleration, deceleration, and shock loads.

- Speed and Acceleration: Take into account the required speed and acceleration of the system. High-speed applications may require special chain designs to maintain stability and reduce wear.

- Environmental Conditions: Consider the operating environment, including temperature variations, moisture levels, presence of chemicals or corrosive substances, and exposure to dust or debris. Choose a chain material and coating that can withstand the specific environmental conditions.

- Space Limitations: Evaluate the available space for installing the chain system. Consider factors such as clearance requirements, vertical or horizontal orientation, and any limitations imposed by surrounding equipment or structures.

- Maintenance and Lubrication: Determine the maintenance requirements of the chain system, including lubrication needs and accessibility for inspection and repairs. Consider if a self-lubricating or low-maintenance chain option is desirable.

- Noise and Vibration: Assess the noise and vibration levels associated with the chain system. Choose a chain design that minimizes noise and ensures smooth operation.

- Service Life and Durability: Estimate the expected service life of the chain system based on the application requirements and the durability of the chosen chain material and design.

- Safety Considerations: Ensure that the design adheres to safety standards and guidelines, including proper guarding, emergency stops, and adequate tensioning mechanisms.

- Compatibility and Interchangeability: Consider the compatibility and interchangeability of the chain system with other components, such as sprockets, shafts, and accessories, to facilitate easy installation, replacement, and maintenance.

By carefully considering these factors during the design phase, engineers can create an industrial chain system that meets the specific requirements of the application, ensures efficient operation, and maximizes the lifespan of the chain system.

editor by CX 2023-12-11

China high quality Wholesale Factory Long Pitch Heavy Corn Wheat Rice Duty System C2050 C2060 Industrial Chain All Kinds of Transmission Chain Conveyor Chain Roller Chain

Product Description

| Model NO. | 06C/08A/10A/12A/16A/20A/24A/28A/32A/40A/06B/08B/10B/12B/16B/20B/24B/28B/32B/40B-1/2/3 Heavy duty |

| Chain Model | Roller Chains |

| Structure (for Chain) | Roller Chain |

| Specification | GB/T, DIN, ANSI, ISO, BS, JIS. |

| Origin | HangZhou, ZheJiang |

| Color | Solid Color |

| Chain Color | Customized |

Our company

Wolff Chain Co. is 1 of the professional chain manufacturers in China. We focus on reseaching, manufacturing and trading of the chain drive with famous brands — “DOVON” and “DECHO”. We supply OEM services for many famous enterprises such as SUZUKI, XIHU (WEST LAKE) DIS., FAW, AGCO, JUMING as well.

Wolff mainly producing the Transmission chains,Conveyor chains,Dragging Chains,Silent chains,Leaf chains,Roller chains,Special chain and many other series of chain products. Our technicians a have improved the chains quality to the world-level. High quality material selection, powerful and precise heat-treatment technology and excellent assembly methods ensure Wolff chains meet the tough and strict requirements for machines and vehicles.

All of our products completely conform to the international standard such as ISO\DIN\ANSI\BS\JIS, etc. Wolff has been successfully certified by ISO9001 Quality Management System,SGS inspection and BV inspection. Wolff chains can be widely applied to many industries including automobile, motorcycle, forklift, wood processing machine, constructure machine, packing machine, food machine,tobacco machine and agricultural equipments. Wolff chains are popular in America,South America,Europe,Middle East, South East Asia and Africa markets.

Our workshop

Our certification

Welcome to our exhibition

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in single color box. If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance. Other payments terms, pls negotiate with us in advance, we can discuss.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.We welcome sample order.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Food Machinery, Marine, Mining Equipment |

| Surface Treatment: | Oil Blooming |

| Structure: | Roller Chain |

| Material: | Carbon Steel |

| Type: | Short Pitch Chain |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the advantages of using a silent chain in an industrial application?

A silent chain, also known as an inverted tooth chain or toothed belt, offers several advantages when used in industrial applications:

1. Quiet operation: Silent chains are designed to minimize noise during operation. The toothed design allows for smooth engagement and disengagement of the chain, resulting in reduced noise levels compared to other chain types. This is particularly beneficial in applications where noise reduction is important, such as in indoor environments or noise-sensitive areas.

2. High load-carrying capacity: Silent chains are capable of carrying heavy loads due to their robust construction. The interlocking toothed design provides excellent power transmission capabilities, allowing for efficient transfer of high torque and load-bearing capacity. This makes silent chains suitable for applications that require heavy-duty performance.

3. Precise positioning and synchronization: Silent chains provide precise positioning and synchronization between the driving and driven components. The toothed profile ensures accurate motion control, making them ideal for applications that require precise timing, such as conveyors, robotics, and automated systems.

4. Low maintenance requirements: Silent chains require minimal maintenance compared to other chain types. The toothed design reduces the need for frequent lubrication, tensioning, and adjustments. This results in lower maintenance costs and less downtime for maintenance activities.

5. High efficiency: Silent chains have high power transmission efficiency due to their positive engagement between the teeth. This means that less energy is wasted during operation, resulting in improved overall system efficiency.

6. Durability and longevity: Silent chains are designed to withstand demanding industrial environments. They are constructed from high-quality materials, such as alloy steel or stainless steel, which provide excellent strength, wear resistance, and corrosion resistance. This ensures a long service life and reduces the need for frequent replacements.

7. Wide range of applications: Silent chains can be used in various industrial applications, including power transmission systems, conveyors, packaging machinery, printing presses, machine tools, and automotive timing systems. Their versatility makes them suitable for a wide range of industries, including manufacturing, automotive, food processing, and pharmaceutical.

Overall, the advantages of using a silent chain in an industrial application include quiet operation, high load-carrying capacity, precise positioning, low maintenance requirements, high efficiency, durability, and versatility. These benefits make silent chains a preferred choice for many industrial applications where reliable and efficient power transmission is required.

What are the environmental considerations when using an industrial chain?

When using an industrial chain, there are several environmental considerations to take into account:

1. Lubrication: Proper lubrication of the chain is important not only for its performance but also for environmental reasons. Using environmentally-friendly lubricants can help minimize the impact on the environment, especially in applications where there is a risk of lubricant leakage or contamination.

2. Material Selection: Choosing the right materials for the chain and its components is crucial. Opting for materials that are resistant to corrosion and wear can extend the chain’s lifespan and reduce the need for frequent replacements, thus minimizing waste.

3. Maintenance and Inspection: Regular maintenance and inspection of the chain can help identify any potential issues early on, preventing unexpected failures and reducing the environmental impact of unplanned downtime and repairs.

4. Noise and Vibration: Industrial chains can generate noise and vibrations during operation, which may have environmental implications, especially in noise-sensitive areas or where worker comfort is a priority. Implementing measures to minimize noise and vibration, such as proper lubrication, chain tensioning, and damping systems, can help mitigate these effects.

5. Waste Management: Proper disposal and recycling of worn-out or damaged chain components are important to minimize the environmental impact. Recycling programs or partnering with responsible waste management companies can ensure that discarded chain components are properly handled and disposed of in an environmentally friendly manner.

By considering these environmental factors and implementing appropriate measures, the use of industrial chains can be made more sustainable and environmentally responsible.

What is an industrial chain and what is its purpose?

An industrial chain, also known as an industrial conveyor chain, is a mechanical device used in various industries for the purpose of conveying or transferring materials or products from one point to another within a production or manufacturing process.

Industrial chains are typically made up of a series of interconnected links, which can be composed of metal, plastic, or other materials depending on the application requirements. These links form a continuous loop that moves materials along the chain’s path.

The primary purpose of an industrial chain is to facilitate the smooth and efficient movement of materials or products within a production system. They are designed to withstand heavy loads, resist wear and corrosion, and operate reliably in demanding industrial environments.

Industrial chains find applications in various industries such as automotive, food and beverage, packaging, mining, agriculture, and many others. They are used in a wide range of processes including assembly lines, material handling systems, conveying systems, and production equipment.

By utilizing an industrial chain, manufacturers can achieve increased productivity, improved workflow, and streamlined operations. The chain’s ability to transport materials or products allows for efficient material flow, reduced manual handling, and enhanced automation.

Overall, the purpose of an industrial chain is to enable the smooth and efficient movement of materials or products, contributing to the overall effectiveness and productivity of industrial processes.

editor by CX 2023-10-18

China Good quality Attachment Roller Chain Industrial Single Strand Steel Conveyor Chain

Product Description

OUR PRODUCTS LIST:

A and B series single/double/triple standard roller chain and no-standard roller chain

| DIN/ISO | ANSI | Pitch | Roller | Width | Pin | Pin | Lnner | Plate | Ultimate | Average | weight | |

| KIN/ISO | ANSL | between | diameter | length | plate | thick | tensile | tensile | per | |||

| Chain | Chain | inner plates | depth | -ness | strength | strength | meter | |||||

| No. | No. | P | d1 | b1 | d2 | L | Lc | h2 | T | Q | Q0 | q |

| max | min | max | max | max | max | max | min | |||||

| mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kN | kg/m | ||

| *03C | *15 | 4.7625 | 2.48 | 2.38 | 1.62 | 6.1 | 6.9 | 4.3 | 0.6 | 1.80/409 | 2 | 0.08 |

| *04C-1 | *25 | 6.35 | 3.3 | 3.18 | 2.31 | 7.9 | 8.4 | 6 | 0.8 | 3.50/795 | 4.6 | 0.15 |

| *06C-1 | *35 | 9.525 | 5.08 | 4.77 | 3.58 | 12.4 | 13.17 | 9 | 1.3 | 7.90/1795 | 10.8 | 0.33 |

| 085-1 | 41 | 12.7 | 7.77 | 6.25 | 3.58 | 13.75 | 15 | 9.91 | 1.3 | 6.67/1516 | 12.6 | 0.41 |

| 08A-1 | 40 | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 17.8 | 12 | 1.5 | 14.10/3205 | 17.5 | 0.62 |

| 10A-1 | 50 | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 22.2 | 15.09 | 2.03 | 22.20/5045 | 29.4 | 1.02 |

| 12A-1 | 60 | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18 | 2.42 | 31.80/7227 | 41.5 | 1.5 |

| 16A-1 | 80 | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 35 | 24 | 3.25 | 59.70/12886 | 69.4 | 2.6 |

| 20A-1 | 100 | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 88.50/20114 | 109.2 | 3.91 |

| 24A-1 | 120 | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 127.00/28864 | 156.3 | 5.62 |

| 28A-1 | 140 | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 172.40/39182 | 212 | 7.5 |

| 32A-1 | 160 | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 226.80/51545 | 278.9 | 1.1 |

| 36A-1 | 180 | 57.15 | 35.71 | 35.48 | 17.46 | 72.8 | 78.6 | 53.6 | 7.2 | 280.20/63682 | 341.8 | 13.45 |

| 40A-1 | 200 | 63.5 | 39.68 | 37.85 | 19.85 | 80.3 | 87.2 | 60 | 8 | 353.80/80409 | 431.6 | 16.15 |

| 48A-1 | 240 | 76.2 | 47.63 | 47.35 | 23.81 | 90.5 | 103 | 72.39 | 9.5 | 51.30/115977 | 622.5 | 23.2 |

| DIN/ISO | Pitch | Roller | Width | Pin | Pin | Lnner | Plate | Ultimate | Average | weight | |

| KIN/ISO | between | diameter | length | plate | thick | tensile | tensile | per | |||

| Chain | inner plates | depth | -ness | strength | strength | meter | |||||

| No. | P | d1 | b1 | d2 | L | Lc | h2 | T | Q | Q0 | q |

| max | min | max | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | mm | mm | mm | kN/LB | kN | kg/m | |

| 04B-1 | 6 | 4 | 2.8 | 1.85 | 6.8 | 7.8 | 5 | 0.6 | 3.2/682 | 3.2 | 0.11 |

| 05B-1 | 8 | 5 | 3 | 2.31 | 8.2 | 8.9 | 7.1 | 0.8 | 5.0/1136 | 5.9 | 0.2 |

| *06B-1 | 9.525 | 6.35 | 5.72 | 3.28 | 13.15 | 14.1 | 8.2 | 1.3 | 9.0/2045 | 10.4 | 0.41 |

| 08B-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.7 | 18.2 | 11.8 | 1.6 | 18.0/4091 | 19.4 | 0.69 |

| 10B-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.5 | 20.9 | 14.7 | 1.7 | 22.4/5091 | 27.5 | 0.93 |

| 12B-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22.5 | 24.2 | 16 | 1.85 | 29.0/6591 | 32.2 | 1.15 |

| 16B-1 | 25.4 | 15.88 | 17.02 | 8.28 | 36.1 | 37.4 | 21 | 4.15/3.1 | 60.0/13636 | 72.8 | 2.71 |

| 20B-1 | 31.75 | 19.05 | 19.56 | 10.19 | 41.3 | 45 | 26.4 | 4.5/3.5 | 95.0/21591 | 106.7 | 3.7 |

| 24B-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 57.8 | 33.2 | 6.0/4.8 | 160.0/36364 | 178 | 7.1 |

| 28B-1 | 44.45 | 27.94 | 30.99 | 15.9 | 65.1 | 69.5 | 36.7 | 7.5/6.0 | 200.0/45455 | 222 | 8.5 |

| 32B-1 | 50.8 | 29.21 | 30.99 | 17.81 | 66 | 71 | 42 | 7.0/6.0 | 250.0/56818 | 277.5 | 10.25 |

| 40B-1 | 63.5 | 39.37 | 38.1 | 22.89 | 82.2 | 89.2 | 52.96 | 8.5/8.0 | 355.0/80682 | 394 | 16.35 |

| 48B-1 | 76.2 | 48.26 | 45.72 | 29.24 | 99.1 | 107 | 63.8 | 560.0/127272 | 621.6 | 25 | |

Products show

Our workshop

Our hot treatment equipment

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in single color box. If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance. Other payments terms, pls negotiate with us in advance, we can discuss.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.We welcome sample order.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

| Material: | Alloy |

|---|---|

| Structure: | Combined Chain |

| Surface Treatment: | Electroplating |

| Chain Size: | 1/2"*3/32" |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Transport Package: | Non-Fumigation Wooden Box, by Air, by Ocean |

| Samples: |

US$ 2/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you determine the expected lifespan of an industrial chain?

The expected lifespan of an industrial chain can vary depending on various factors. Here's how you can determine the expected lifespan of an industrial chain:

- Manufacturer’s specifications: Start by referring to the manufacturer’s specifications and guidelines for the industrial chain. Manufacturers often provide information about the estimated lifespan based on the chain’s design, material, and intended use.

- Operating conditions: Evaluate the operating conditions in which the industrial chain will be used. Factors such as temperature, humidity, exposure to chemicals or abrasive materials, and load conditions can significantly impact the chain’s lifespan. Consider whether the chain will be subject to heavy loads, frequent starts and stops, or continuous operation.

- Maintenance practices: Proper maintenance is essential for prolonging the lifespan of an industrial chain. Follow the manufacturer’s recommended maintenance procedures, including regular cleaning, lubrication, and inspection. Neglecting maintenance can lead to premature wear and reduce the chain’s lifespan.

- Chain wear monitoring: Implement a chain wear monitoring program to track the condition of the chain over time. This can involve measuring the elongation of the chain, inspecting for signs of wear, and conducting regular maintenance checks. By monitoring wear, you can anticipate when the chain may need replacement.

- Application-specific factors: Consider any unique factors related to the specific application. This may include factors like shock loads, vibration, misalignment, or exposure to extreme conditions. These factors can accelerate wear and impact the chain’s lifespan.

- Historical data and experience: Drawing from historical data and experience with similar applications can provide insights into the expected lifespan of the industrial chain. If there are past records of chain performance in similar operating conditions, they can serve as a reference point.

It's important to note that determining the exact lifespan of an industrial chain is challenging as it depends on various factors. Regular monitoring, proper maintenance, and adherence to recommended operating conditions can help maximize the chain's lifespan.

How does an industrial chain compare to other types of power transmission systems?

An industrial chain is a type of power transmission system that offers several advantages compared to other systems:

- Strength and durability: Industrial chains are designed to handle heavy loads and withstand tough operating conditions. They are known for their high strength and durability, making them suitable for demanding industrial applications.

- Efficiency: Industrial chains provide efficient power transmission, minimizing energy loss during operation. They offer high mechanical efficiency, which is especially important in applications that require precise and consistent power transfer.

- Flexibility: Industrial chains are flexible in terms of design and configuration. They can be easily adapted to various applications and can transmit power over long distances, making them suitable for a wide range of industrial machinery and equipment.

- Cost-effectiveness: Industrial chains are often cost-effective compared to alternative power transmission systems. They are relatively simple in design, easy to manufacture, and have a lower initial cost. Additionally, their durability and longevity reduce the need for frequent replacements, resulting in long-term cost savings.

- Reliability: Industrial chains are known for their reliability and consistent performance. When properly maintained and operated within their load and speed limits, they can provide reliable power transmission for extended periods.

- Versatility: Industrial chains can accommodate various environmental conditions, including high temperatures, corrosive environments, and high-speed applications. They can be made from different materials and configured with specific features to suit specific application requirements.

While industrial chains offer numerous advantages, it is essential to consider specific application needs and requirements when selecting a power transmission system. Factors such as load capacity, operating environment, speed, and precision may influence the suitability of an industrial chain compared to alternatives such as belts, gears, or shafts.

What are the signs of wear and tear in an industrial chain?

Monitoring the condition of an industrial chain is essential to identify signs of wear and tear. Here are some common signs to watch for:

- Chain Elongation: Measure the chain’s pitch to check for elongation. Excessive elongation indicates wear in the chain and can lead to poor performance and premature failure.

- Worn Sprocket Teeth: Inspect the sprocket teeth for signs of wear. Worn or misshapen teeth can cause the chain to skip or slip, resulting in decreased efficiency and increased stress on the system.

- Chain Flexibility: Assess the flexibility of the chain by bending it. If the chain is stiff or has tight spots, it may indicate corrosion, inadequate lubrication, or worn components.

- Visible Damage: Look for any visible damage on the chain, such as bent links, cracked or broken plates, or missing pins or rollers. These can weaken the chain’s integrity and compromise its performance.

- Excessive Noise: Unusual noise during operation, such as grinding, rattling, or squeaking, can indicate a problem with the chain. It may be caused by misalignment, inadequate lubrication, or worn components.

- Increased Friction: Check for excessive heat or signs of friction, such as discoloration or hot spots. Increased friction can accelerate wear and lead to premature failure.

- Poor Tension: Assess the chain’s tension by checking for slack or excessive tightness. Improper tension can cause the chain to wear unevenly and affect its performance.

Regular inspections and maintenance are crucial to identify these signs of wear and tear. Addressing issues promptly, such as replacing worn components or adjusting tension, can help prolong the life of the industrial chain and prevent unexpected failures.

editor by CX 2023-09-23

China best 20A Chain Reliable and High Quality Stainless Roller Chain for Industrial

Product Description

Product Description

| 40-1R Roller chain’s specification: 1, Plate material: 40Mn; Pin: 40Cr; Bush and roller: 10# steel 2, Color: Blue., natural black, yellow are available. 3, Technics: advanced heat treatment 4, Standard: ANSI, GB, ISO, DIN 5, 10 ft. rolls with 1 connecting link |

Products Show

Package&Delivery

1.Industrial packing+industrial cartons+pallets

2.Single brand box+brand cartons+pallets

3.Follow customer’s requests

A.Plastic Tubes or Single Boxes ( Usually 10pcs in 1 plastic tube for steel bearings);

B.Cartons ( No more than 30kg for 1 carton )

C. Pallet ( Usually more than 400kg totally will use pallet )

D. Delivery time :7-35 days ( by sea or by air )

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Surface Treatment: | Shot Peen |

| Structure: | Roller Chain |

| Material: | Stainless Steel |

| Type: | Short Pitch Chain |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the benefits of using plastic industrial chains?

Plastic industrial chains offer several advantages in various applications. Here are some benefits of using plastic industrial chains:

- Corrosion resistance: Plastic chains are highly resistant to corrosion, making them suitable for use in corrosive environments where metal chains may degrade over time.

- Chemical resistance: Plastic chains can withstand exposure to a wide range of chemicals without deteriorating, making them ideal for applications in chemical processing or handling.

- Lightweight: Plastic chains are significantly lighter than their metal counterparts, reducing the overall weight of the system and allowing for easier handling and installation.

- Low noise: Plastic chains produce less noise during operation compared to metal chains, making them suitable for applications where noise reduction is important, such as in food processing or packaging.

- Self-lubricating: Some plastic chains are designed with self-lubricating properties, reducing the need for frequent lubrication and maintenance.

- High strength: Despite their lightweight nature, plastic chains can still provide high tensile strength and load-bearing capabilities, making them suitable for various heavy-duty applications.

- Low friction: Plastic chains exhibit low friction characteristics, resulting in smoother and more efficient operation, reducing power consumption and wear.

- Design flexibility: Plastic chains can be molded into various shapes and sizes, allowing for customization and adaptation to specific application requirements.

- Cost-effective: Plastic chains are often more cost-effective compared to metal chains, making them an economical choice for many industrial applications.

Plastic industrial chains offer a range of benefits, including resistance to corrosion, chemicals, and noise, lightweight design, self-lubrication, and design flexibility, making them suitable for a wide range of industries and applications.

How do you select the appropriate lubricant for an industrial chain?

Selecting the right lubricant for an industrial chain is crucial to ensure its smooth operation, reduce wear, and extend its lifespan. Here are the key factors to consider when choosing the appropriate lubricant:

1. Chain type: Different types of industrial chains may have specific lubrication requirements. Refer to the manufacturer’s recommendations or technical specifications to determine the compatible lubricant.

2. Operating conditions: Consider the operating environment, such as temperature, humidity, and exposure to contaminants like dust or chemicals. Choose a lubricant that can withstand the specific conditions and provide adequate protection.

3. Load and speed: Evaluate the load capacity and speed of the chain system. High loads or high speeds may require lubricants with enhanced film strength and viscosity to prevent metal-to-metal contact.

4. Lubricant properties: Look for lubricants with properties such as high viscosity index, good thermal stability, anti-wear additives, corrosion resistance, and water resistance. These properties contribute to better lubrication and protection.

5. Lubrication method: Consider the lubrication method available for the chain system, such as manual lubrication, automatic lubrication systems, or oil bath lubrication. Ensure the selected lubricant is compatible with the chosen lubrication method.

6. Maintenance schedule: Assess the maintenance intervals and frequency of lubrication. Some lubricants offer longer-lasting performance, reducing the frequency of relubrication and maintenance requirements.

7. Environmental impact: Take into account any environmental regulations or considerations when selecting a lubricant. Choose environmentally friendly options, such as biodegradable or low-toxicity lubricants, if required.

Consult with lubricant suppliers or industry experts for specific recommendations based on your application and chain system requirements. They can provide valuable insights and help you select the most suitable lubricant to optimize the performance and longevity of your industrial chain.

What are the different types of industrial chains?

Industrial chains are available in various types, each designed to suit specific applications and requirements. Here are some common types of industrial chains:

- Roller chains: Roller chains are the most common type of industrial chains. They consist of a series of interconnected rollers that engage with the sprockets to transmit power and facilitate the movement of materials.

- Conveyor chains: Conveyor chains are specifically designed for use in conveyor systems. They have attachments or slats that allow them to carry materials or products along a horizontal or inclined path.

- Leaf chains: Leaf chains are made up of interlocking plates or links that provide high tensile strength and resistance to fatigue. They are commonly used in applications that require heavy lifting or load-bearing capabilities.

- Wire mesh chains: Wire mesh chains are composed of interconnected wire mesh links. They are often used in applications that involve high-temperature environments, such as oven conveyors or drying processes.

- Bucket elevator chains: Bucket elevator chains are designed for vertical lifting applications, typically used in industries such as agriculture, mining, and construction. They feature buckets that carry materials as they move upward.

- Precision chains: Precision chains are engineered to provide precise positioning and accurate movement. They are commonly used in applications such as robotics, automation, and CNC machinery.

- Specialty chains: Specialty chains are designed for specific applications and industries. Examples include agricultural chains, escalator chains, drag chains, and many more.

Each type of industrial chain has its unique design features, materials, and applications. The selection of the appropriate chain type depends on factors such as load capacity, speed, environment, and specific operational requirements.

editor by CX 2023-09-05

China Good quality Industrial Double Pitch Conveyor Roller Chain Conveyor Roller Chain

Product Description

CZPT rollers enhance rotation on the bushing while reducing impact loads on the sprocket tooth during operation.

All components are heat treated to achieve maximum strength. All components are heat treated to achieve maximum strength.

Pre-loaded during the manufacturing process to minimize initial elongation.

Hot dipped lubrication ensures 100% lubrication of all chain components to extend wear life and reduce maintenance costs.

| ISO NO. |

ANSI NO. |

PITCH | ROLLER LINK WIDTH |

ROLLER DIA |

PIN | PLATE | MIN. TENSILE STRENGTH |

AVG. TENSILE STRENGTH |

MAX. ALLOWABLE LOAD |

|||

| P | W | D | d | L | Lc | H | T | |||||

| mm | mm | mm | mm | mm | mm | mm | mm | kgf | kgf | kgf | ||

| C208A | C2040 | 25.40 | 7.85 | 7.95 | 3.98 | 17.80 | 21.00 | 12.00 | 1.50 | 1,420 | 1,950 | 280 |

| C208AL | C2042 | 25.40 | 7.85 | 15.88 | 3.98 | 17.80 | 21.00 | 12.00 | 1.50 | 1,420 | 1,950 | 280 |

| C210A | C2050 | 31.75 | 9.40 | 10.16 | 5.09 | 21.80 | 25.00 | 15.00 | 2.00 | 2,220 | 3,100 | 450 |

| C210AL | C2052 | 31.75 | 9.40 | 19.05 | 5.09 | 21.80 | 25.00 | 24.10 | 2.00 | 2,220 | 3,100 | 450 |

| C212 | C2060 | 38.10 | 12.58 | 11.91 | 5.96 | 26.90 | 31.00 | 30.10 | 2.35 | 3,190 | 4,200 | 640 |

| C212AL | C2062 | 38.10 | 12.58 | 22.23 | 5.96 | 26.90 | 31.00 | 36.20 | 2.35 | 3,190 | 4,200 | 640 |

| C216A | C2080 | 50.80 | 15.75 | 15.88 | 7.94 | 33.50 | 38.00 | 42.20 | 3.20 | 5,680 | 7,500 | 1,100 |

| C216AL | C2082 | 50.80 | 15.75 | 28.58 | 7.94 | 33.50 | 38.00 | 48.20 | 3.20 | 5,680 | 7,500 | 1,100 |

| C220A | C2100 | 63.50 | 18.90 | 19.05 | 9.54 | 41.10 | 47.00 | 54.30 | 4.00 | 8,870 | 12,100 | 1,900 |

| C220AL | C2102 | 63.50 | 18.90 | 39.67 | 9.54 | 41.10 | 47.00 | 60.30 | 4.00 | 8,870 | 12,100 | 1,900 |

| C224A | C2120 | 76.20 | 25.23 | 22.23 | 11.11 | 50.80 | 57.00 | 72.40 | 4.70 | 12,770 | 16,000 | 2,550 |

| C224AL | C2122 | 76.20 | 25.23 | 44.45 | 11.11 | 50.80 | 57.00 | 18.00 | 4.70 | 12,770 | 16,000 | 2,550 |

| Usage: | Transmission Chain, Conveyor Chain, Roller Chains |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Polishing |

| Feature: | Heat Resistant |

| Chain Size: | 1"~3" |

| Structure: | Roller Chain |

| Samples: |

US$ 10/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the future trends and advancements in industrial chain technology?

Industrial chain technology is continuously evolving to meet the changing needs of various industries. Here are some future trends and advancements that can be observed in industrial chain technology:

- Increased Automation: Industrial chains are becoming an integral part of automated systems. The advancement of robotics, IoT (Internet of Things), and artificial intelligence is driving the integration of industrial chains with smart technologies. This includes features such as remote monitoring, predictive maintenance, and real-time data analysis for optimizing chain performance and overall system efficiency.

- Improved Materials and Coatings: Ongoing research and development efforts are focused on developing advanced materials with enhanced properties for industrial chains. This includes materials with superior strength, durability, corrosion resistance, and wear resistance. Additionally, the development of advanced surface coatings and treatments further enhances the performance and lifespan of industrial chains.

- Energy Efficiency: Energy efficiency is a growing concern in industrial applications. Future industrial chains are likely to incorporate designs and features that reduce energy consumption, such as optimized chain profiles, reduced friction coatings, and improved lubrication systems. These advancements aim to minimize power losses and improve overall system efficiency.

- Integration with Digital Technologies: Industrial chains are expected to be increasingly integrated with digital technologies for seamless communication and data exchange. This integration enables better monitoring of chain performance, real-time diagnostics, and the ability to make data-driven decisions for maintenance and optimization. Digital twins, virtual simulations, and augmented reality (AR) are also emerging trends that allow for improved chain design, testing, and troubleshooting.

- Enhanced Safety Features: Safety remains a top priority in industrial settings. Future industrial chains may incorporate advanced safety features such as integrated sensors for detecting chain wear, overload conditions, or abnormal operating parameters. These features can provide early warning signs and help prevent accidents or equipment failures.

The future of industrial chain technology is driven by the need for increased efficiency, reliability, and safety. The integration of smart technologies, improved materials, energy efficiency measures, digitalization, and enhanced safety features are expected to shape the advancements in industrial chain technology in the coming years.

What are the noise levels associated with industrial chains?

The noise levels associated with industrial chains can vary depending on several factors, including chain design, lubrication, and operating conditions.

Chain Design: The design of the industrial chain, including the type of chain and its construction, can impact noise levels. Chains with smoother surfaces and precision manufacturing techniques tend to produce less noise.

Lubrication: Proper lubrication of the chain is essential for reducing noise. Applying a suitable lubricant to the chain can minimize friction and vibration, resulting in quieter operation.

Operating Conditions: The operating conditions of the industrial chain, such as the load, speed, and tension, can also affect noise levels. Higher loads and speeds, as well as inadequate tensioning, can increase noise levels.

Overall, it is important to consider noise levels when using industrial chains, particularly in noise-sensitive environments. Implementing proper chain design, regular lubrication, and maintaining appropriate operating conditions can help minimize noise and create a more comfortable work environment.

How does an industrial chain work in a manufacturing process?

An industrial chain plays a crucial role in a manufacturing process by facilitating the movement of materials or products along a predetermined path. Here’s a detailed explanation of how an industrial chain works:

- Input of materials: The manufacturing process begins with the input of raw materials or components onto the industrial chain. These materials are usually placed onto the chain manually or through automated systems.

- Chain movement: The industrial chain is set into motion, either by a motor or by connecting it to a power source. As the chain moves, it carries the materials or products along its path.

- Transfer and handling: The materials or products are transferred from one workstation to another as they move along the industrial chain. This transfer can involve various processes such as assembly, inspection, packaging, or any other manufacturing operation.

- Control and synchronization: The movement of the industrial chain is controlled and synchronized to ensure proper timing and coordination of the manufacturing process. This can be achieved through the use of sensors, actuators, and control systems that monitor and adjust the speed, direction, and position of the chain.

- Output and completion: As the materials or products reach the end of the industrial chain, they are either ready for further processing or considered as finished goods. They are then removed from the chain and directed to the next stage of the manufacturing process or prepared for shipment.

The working principle of an industrial chain involves the continuous loop movement of the chain, which allows for the smooth and controlled transfer of materials or products. The chain’s design, including the type of links, pitch, and attachments, is optimized to meet the specific requirements of the manufacturing process, such as load capacity, speed, and environmental conditions.

By utilizing an industrial chain in a manufacturing process, companies can achieve increased efficiency, improved productivity, and enhanced automation. The precise and reliable movement of materials or products provided by the industrial chain ensures a streamlined and synchronized manufacturing operation.

editor by CX 2023-09-05

China Good quality Industrial Manufactures ANSI Standard 120 24A Conveyor Roller Chain for Transmission

Product Description

Industrial Manufactures ANSI Standard 120 24A Conveyor Roller Chain for Transmission

Product Description

Roller chains conforms to ISO, ANSI, DIN, JIS and other standards. It adopts high-quality materials and advanced processing technology. The roller chains has the characteristics of high tensile strength and high fatigue strength. The roller chain is widely used in construction machinery, agricultural machinery, motorcycles, and automobile transmission. , food conveying machinery, logistics conveying machinery, packaging machinery and other fields, to transmit power for various mechanical facilities

| Product Name | Industrial Manufactures ANSI Standard 120 24A Conveyor Roller Chain for Transmission |

| Material | carbon steel,stainless steel and so on |

| Standard | DIN GB ISO JIS |

| DIN/ISO chain No. | 08A,10A,12A,16A,20A,24A,28A,32A,36A,40A,48A;08B 10B 12B 16B and so on |

| Key Words | Roller Chains |

| Application Area | Food processing, pharmaceutical and chemical industries, electronics, household appliances, automotive manufacturing, metallurgy, sewage treatment |

| Delivery time | 3-10 days depends on quantity needed |

Product Parameters

Company Profile

HangZhouTerry Machinery Co.,Ltd is a leading internatioal Machinery Manufacturer. The growing economics and convenient transportation of HangZhou benefits the development of Terry Machinery. Our products are utilized in commercial, industrial and custom application. Terry Machinery is specialized in engineering machinery bearing and vehicle industrial bearing. Our products have been exported over 53 countries.The goal of Terry Machinery is to provide out customers with widest range of products at lowest price, high quality with the best service.

Certifications

Our Advantages

1. World-Class Roller Chains

We provide our customers with all types of indigenous chains with world-class quality.

2. Free Samples:

We can provide free 1-10 meters,but you need bear shipping cost.

3. Genuine products With Excellent Quality:

The company has always proved the 100% quality products it provides with genuine intent.

4. Many Cheap International Forwarders:

We have many International forwarders partner and all kinds of shipping channel,keep sure your goods arrived yourside safe and fast.

5. Quick Delivery:

The company provides just-in-time delivery with its streamlined supply chain.

Packaging & Shipping

FAQ

1.What is the minimum order quantity for this product?

Depending on the size of the bearing, the MOQ is variable, if you are interested, you can contact me for a quote.

2.What is your latest delivery time?

Most orders will be shipped within 3-10 days of payment being received.

3.What are the advantages of your company’s services compared to other companies?

Answer questions online 24 hours a day, reply in a timely manner, and provide various documents required by customers for customs clearance or sales. 100% after-sales service.

4.Which payment method does your company support?

Do our best to meet customer needs, negotiable.

5.Do you accept OEM or customized service?

In addition to standard products, we also supply non-standard and modified standard products for special application. Meanwhile, we provide OEM service.

High Precision Bearing Steel CZPT CZPT CZPT 6205 6206 Deep Groove Ball Bearing for Motorcycles Part

High Precision Bearing Steel CZPT CZPT CZPT 6205 6206 Deep Groove Ball Bearing for Motorcycles Part

High Precision Bearing Steel CZPT CZPT CZPT 6205 6206 Deep Groove Ball

Please feel free to contact us, if you have any other question

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car, CNC Machine |

| Surface Treatment: | Polishing |

| Structure: | Roller Chain |

| Material: | Carbon Steel |

| Type: | Short Pitch Chain |

| Samples: |

US$ 1/Meter

1 Meter(Min.Order) | |

|---|

What are the safety measures for working with heavy-duty industrial chains?

Working with heavy-duty industrial chains requires adherence to proper safety measures to ensure the well-being of personnel and the prevention of accidents. Here are some key safety measures to consider:

- Personal protective equipment (PPE): Operators and personnel working with industrial chains should wear appropriate PPE, including safety goggles, gloves, steel-toed boots, and protective clothing, to protect against potential hazards.

- Training and education: Ensure that all individuals involved in working with industrial chains receive proper training and education on safe operating procedures, equipment handling, and maintenance practices. This includes understanding the specific risks and hazards associated with heavy-duty chains.

- Machine guarding: Implement machine guarding measures to prevent accidental contact with moving chain components. This may include installing barriers, safety covers, or interlocking devices to prevent unauthorized access to the chain and related machinery.

- Proper installation: Follow manufacturer guidelines and recommendations for the proper installation of heavy-duty industrial chains. Improper installation can lead to chain failure or accidents during operation. Ensure that chains are correctly tensioned, aligned, and securely fastened.

- Maintenance and inspection: Regularly inspect and maintain the industrial chains to identify any signs of wear, damage, or fatigue. Replace worn or damaged components promptly to prevent chain failure. Follow a maintenance schedule that includes lubrication, tension adjustment, and inspection of chain links, sprockets, and other relevant parts.

- Lockout/tagout procedures: Establish lockout/tagout procedures to ensure that industrial chains are de-energized and secured before performing maintenance, repair, or adjustment tasks. This helps prevent accidental startup or movement of the chain during work.

- Risk assessment: Conduct a comprehensive risk assessment of the work environment to identify potential hazards associated with heavy-duty industrial chains. Implement appropriate control measures to mitigate the identified risks.

- Emergency preparedness: Have emergency protocols in place, including clear evacuation routes, accessible emergency stop buttons, and proper communication channels to respond quickly to any incidents or accidents involving industrial chains.

It is essential to follow local safety regulations, industry standards, and manufacturer recommendations specific to the heavy-duty industrial chains being used. Regular safety training, awareness, and ongoing monitoring of the work environment contribute to a safe and productive operation involving industrial chains.

What are the common causes of industrial chain failures?

Industrial chain failures can occur due to various factors:

- Excessive load: Applying a load that exceeds the chain’s capacity can lead to stress and failure. It is important to consider the chain’s rated load and choose the appropriate chain for the application.

- Inadequate lubrication: Insufficient or improper lubrication can result in increased friction and wear, leading to premature chain failure. Regular lubrication with the recommended lubricant and following the manufacturer’s guidelines is crucial.

- Improper tensioning: Incorrect chain tension can cause misalignment, premature wear, and failure. Proper tensioning ensures optimal performance and longevity of the chain.

- Misalignment: Poor alignment between the sprockets can cause the chain to wear unevenly and increase the risk of failure. Proper alignment of the sprockets is essential for smooth operation.

- Wear and tear: Continuous use without proper maintenance and regular inspection can result in chain fatigue, elongation, and eventual failure. Regular inspection and timely replacement of worn-out components are necessary to prevent failure.

- Corrosion: Exposure to corrosive environments can weaken the chain material and compromise its integrity. Using corrosion-resistant chains or applying appropriate coatings can mitigate the risk of corrosion-related failures.

- Lack of maintenance: Neglecting routine maintenance tasks such as cleaning, lubrication, and inspection can lead to chain degradation and eventual failure. Regular maintenance is essential to ensure optimal chain performance and longevity.

How is an industrial chain different from a regular chain?

An industrial chain differs from a regular chain in terms of its design, construction, and intended application. Here are some key differences:

- Strength and Durability: Industrial chains are specifically designed to handle heavy loads and withstand harsh operating conditions in industrial settings. They are constructed using high-quality materials and undergo rigorous testing to ensure strength and durability.

- Precision Engineering: Industrial chains are engineered with precision to meet specific performance requirements. They are manufactured to strict tolerances, ensuring precise fit and proper engagement with sprockets, resulting in reliable and efficient power transmission.

- Specialized Designs: Industrial chains come in a variety of specialized designs to accommodate different applications. They may feature specific link shapes, roller configurations, or surface treatments tailored to meet the unique needs of various industries, such as conveying, lifting, or power transmission.

- Lubrication Requirements: Industrial chains often require regular lubrication to minimize friction and wear. They may incorporate lubrication systems or be designed to accommodate external lubrication methods to ensure optimal performance and longevity.

- Application Focus: Regular chains are commonly used for lighter-duty applications such as securing objects or supporting light loads. Industrial chains, on the other hand, are designed for heavy-duty industrial applications, including machinery, conveyors, mining equipment, and other demanding environments where high load capacity and reliability are crucial.

- Industry Standards and Regulations: Industrial chains are often subject to specific industry standards and regulations to ensure their performance, safety, and compatibility with machinery and equipment used in industrial settings.

Overall, the key distinction lies in the industrial chain’s robustness, precision engineering, specialized designs, and suitability for heavy-duty industrial applications, setting it apart from regular chains commonly used in lighter-duty tasks.

editor by CX 2023-08-29

China Good quality ISO/ANSI/DIN Standard Short Pitch Precision Stainless Steel Hardware Transmission Motorcycle Industrial Roller Chain

Product Description

ISO/ANSI/DIN Standard Short Pitch Precision Stainless Steel Hardware Transmission Motorcycle Industrial Roller Chain

Product Description

1. Material: Stainless Steel 304 & 316 / Alloy Carbon Steel

2. Surface Treatment: Shot peening / Zinc-plated / Nickel-plated / Dacromet-plated

3. Chain No:

35SS-1, 40SS-1, 50SS-1, 60SS-1, 80SS-1, 100SS-1, 120SS-1, 140SS-1;

35SS-2, 40SS-2, 50SS-2, 60SS-2, 80SS-2, 100SS-2, 120SS-2, 140SS-2;

35SS-3, 40SS-3, 50SS-3, 60SS-3, 80SS-3, 100SS-3, 120SS-3, 140SS-3;

4. Application: Stainless Steel Chains are used in so many industries, such as machine manufacturing, food machine, etc. Also are suitable for high and low temperature conditions.

5. Characteristic:

1. The chain can be used on the both sides of multi-axle transmission.

2. Easy installation and replacement.

3. It can obtain larger reduction ratio.

4. The roller chain has good elasticity, high strength and each hinge part has lubricating oil, so it can be stored easliy. Thus, compared with the rigid contact tooth, it has good cushioning and vibration absorbing ability.

| Product name | Stainless Steel Roller Chain From China |

| Materials Available | 1. Stainless Steel: SS304, SS316, etc |

| 2. Alloy Steel: 45Mn, 42CrMo, 20CrMo, etc | |

| 3. OEM according to your request | |

| Surface Treatment | Shot peening, Blackening, Oxygenation, Polishing, Zinc-plated, Nickel-plated, Anodized, etc. |

| Characteristic | Fire Resistant, Oil Resistant, Heat Resistant |

| Design criterion | ISO DIN ANSI & Customer’s Drawing |

| Size | Customer’s Drawing & ISO standard |

| Package | Wooden Case / Container and pallet, or made-to-order |

| Certificate | ISO9001: 2008 |

| Advantage | First quality, Best service, Competitive price, Fast delivery |

| Delivery Time | 20 days for samples. 45 days for official order. |

Detailed Photos

View more products,please click here…

Company Profile

| Usage: | Transmission Chain |

|---|---|

| Material: | Stainless steel |

| Structure: | Roller Chain |

| 80-1: | 1" |

| Size: | 50ss-1 |

| Other: | Corrosion Resistance |

| Samples: |

US$ 0/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the advantages of using a silent chain in an industrial application?

A silent chain, also known as an inverted tooth chain or toothed belt, offers several advantages when used in industrial applications:

1. Quiet operation: Silent chains are designed to minimize noise during operation. The toothed design allows for smooth engagement and disengagement of the chain, resulting in reduced noise levels compared to other chain types. This is particularly beneficial in applications where noise reduction is important, such as in indoor environments or noise-sensitive areas.

2. High load-carrying capacity: Silent chains are capable of carrying heavy loads due to their robust construction. The interlocking toothed design provides excellent power transmission capabilities, allowing for efficient transfer of high torque and load-bearing capacity. This makes silent chains suitable for applications that require heavy-duty performance.

3. Precise positioning and synchronization: Silent chains provide precise positioning and synchronization between the driving and driven components. The toothed profile ensures accurate motion control, making them ideal for applications that require precise timing, such as conveyors, robotics, and automated systems.

4. Low maintenance requirements: Silent chains require minimal maintenance compared to other chain types. The toothed design reduces the need for frequent lubrication, tensioning, and adjustments. This results in lower maintenance costs and less downtime for maintenance activities.

5. High efficiency: Silent chains have high power transmission efficiency due to their positive engagement between the teeth. This means that less energy is wasted during operation, resulting in improved overall system efficiency.

6. Durability and longevity: Silent chains are designed to withstand demanding industrial environments. They are constructed from high-quality materials, such as alloy steel or stainless steel, which provide excellent strength, wear resistance, and corrosion resistance. This ensures a long service life and reduces the need for frequent replacements.

7. Wide range of applications: Silent chains can be used in various industrial applications, including power transmission systems, conveyors, packaging machinery, printing presses, machine tools, and automotive timing systems. Their versatility makes them suitable for a wide range of industries, including manufacturing, automotive, food processing, and pharmaceutical.

Overall, the advantages of using a silent chain in an industrial application include quiet operation, high load-carrying capacity, precise positioning, low maintenance requirements, high efficiency, durability, and versatility. These benefits make silent chains a preferred choice for many industrial applications where reliable and efficient power transmission is required.

What safety precautions should be followed when working with industrial chains?

Working with industrial chains involves potential hazards, and it is important to follow proper safety precautions to prevent accidents and injuries. Here are some safety guidelines to consider:

- Training and Familiarization: Ensure that workers are properly trained in handling industrial chains, including understanding the risks involved and knowing how to operate, maintain, and inspect them correctly.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as safety glasses, gloves, and steel-toed shoes, to protect against potential hazards, including flying debris, pinch points, and sharp edges.

- Equipment Inspection: Regularly inspect the industrial chain, sprockets, and other related equipment for any signs of damage, wear, or misalignment. If any issues are found, repair or replace the components before using the chain.

- Proper Installation: Follow the manufacturer’s instructions and guidelines for proper installation of the industrial chain, including correct tensioning, alignment, and lubrication. Ensure that the chain is securely attached and that all connections and fasteners are properly tightened.

- Safe Operating Procedures: Adhere to safe operating procedures when using machinery or equipment with industrial chains. Avoid operating the machinery at excessive speeds or overloading the chain beyond its recommended capacity.

- Lockout/Tagout: When performing maintenance or repairs on machinery with industrial chains, follow lockout/tagout procedures to ensure the equipment is de-energized and cannot be accidentally started.

- Avoid Loose Clothing and Jewelry: Do not wear loose clothing, jewelry, or any other items that can get caught in the chain or machinery, posing a risk of entanglement.

- Emergency Stop Devices: Ensure that emergency stop devices are easily accessible and functional to quickly halt the machinery in case of an emergency or entanglement.

- Regular Maintenance: Implement a regular maintenance program to inspect and maintain industrial chains, including lubrication, tensioning, and replacing worn or damaged components.

It is crucial to consult and follow all relevant safety regulations and guidelines specific to your industry and location. Additionally, fostering a safety-conscious work environment, providing proper training and supervision, and promoting a culture of safety awareness among workers can contribute to the prevention of accidents and injuries when working with industrial chains.

How is an industrial chain different from a regular chain?

An industrial chain differs from a regular chain in terms of its design, construction, and intended application. Here are some key differences:

- Strength and Durability: Industrial chains are specifically designed to handle heavy loads and withstand harsh operating conditions in industrial settings. They are constructed using high-quality materials and undergo rigorous testing to ensure strength and durability.

- Precision Engineering: Industrial chains are engineered with precision to meet specific performance requirements. They are manufactured to strict tolerances, ensuring precise fit and proper engagement with sprockets, resulting in reliable and efficient power transmission.

- Specialized Designs: Industrial chains come in a variety of specialized designs to accommodate different applications. They may feature specific link shapes, roller configurations, or surface treatments tailored to meet the unique needs of various industries, such as conveying, lifting, or power transmission.

- Lubrication Requirements: Industrial chains often require regular lubrication to minimize friction and wear. They may incorporate lubrication systems or be designed to accommodate external lubrication methods to ensure optimal performance and longevity.

- Application Focus: Regular chains are commonly used for lighter-duty applications such as securing objects or supporting light loads. Industrial chains, on the other hand, are designed for heavy-duty industrial applications, including machinery, conveyors, mining equipment, and other demanding environments where high load capacity and reliability are crucial.

- Industry Standards and Regulations: Industrial chains are often subject to specific industry standards and regulations to ensure their performance, safety, and compatibility with machinery and equipment used in industrial settings.

Overall, the key distinction lies in the industrial chain’s robustness, precision engineering, specialized designs, and suitability for heavy-duty industrial applications, setting it apart from regular chains commonly used in lighter-duty tasks.

editor by CX 2023-08-09

China supplier High Quality Polished Stainless Steel Chains Without Plating metric roller chain

Product Description

We adhere steady and long-term operation development, at the same time, by virtue of strong talent resources, strict production management and business philosophy, Through the accumulation of experience and tireless pursuit of the future and consummate, constantly self innovation, technology innovation, management innovation, and business ideas innovative, adapt to today’ S product development the trend, to provide you with good quality, competitive price, more stylish products(Stainless steel fashion chain,Copper fashion chain,Alloy fashion chain,Iron fashion chain,Aluminum fashion chain,Metal Accessories).

Advantage:

1/ Different size, color and material can be available.

2/ OEM/Customers’ design are welcome!

3/ Available standard: Lead free, nickel free & environment friendly

4/ Order quantity as showed on the above choose.

5/ As We have our own factory and company. We also can produce large orders.

6/We can print the customers’ logo as per the customer’s request;

7/ Good quality with competitive price, and timely delivery.

8/ With many years experience in foreign trade will help provide you good & warm service.

Package:

Normally each packed in a PP bag.

We have right to export the goods by ourself. Our products are selling well in the oversea

Market, because of our newly popular design, excellent quality, reasonable price, best

Service, prompt delivery;

Welcome customers to place orders from us. We believe that you will be our regular customer

After you cooperate with us.

| Color | Nickel , gold , light gold ,rose gold, gunmetal , black , antique brass , brushed antique brass , antique silver, brushed antique silver …etc. Can custom the color as your requirements |

| Surface treatment | Electroplating |

| Length | Can custom the length as your requirements |

| MOQ | 300 yards |

| Price Term | EXW , FOB , CIF , DDP (Delivery to your office) |

| Delivery Time | 10-15 days |

| Payment Term | T/T , WESTERN UNION , PAYPAL |

| Eco-friendly | Nickel free , lead free … |

| Corrosion resistance test | ≥24hours ; ≥48 hours ; as your requests |

| Sample | If we have stock , we can offer free samples.but you should pay the freight charge |

| Support OEM / ODM | |

| Usage: | Shirts, Coats, Bra, Pants/Trousers |

|---|---|

| Gender: | Unisex |

| Age Group: | Adults |

| Transport Package: | Carton |

| Specification: | 7*15 mm |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Roller Chains

There are several types of roller chains available. These chains have different properties and serve different purposes. Here you will learn about diamond roller chains, X-ring and O-ring chains, inverted tooth chains, and self-lubricating chains. You can choose the type that best suits your needs by reading this article. It will also help you make an informed decision. Buying the right roller chain for your needs is easy. Hope this article is helpful to you!

Diamond roller chain

Diamond roller chains are more efficient than other chains and can significantly extend chain life. The superior design of the chain prevents internal rust from seeping out. Additionally, Diamond ACE features a corrosion-resistant exterior and a zinc-nickel pre-assembled coating that provides extended corrosion protection and wear resistance. These features reduce chain downtime and labor costs, saving a building materials manufacturing company nearly $33,000 over the life of its machines.

Diamond series chains lead the industry in quality and durability, with industry-leading tensile strength and the lowest total cost of ownership. With a diverse product portfolio including standard chains, specialty chains, and custom chains, the company is sure to provide the right chain for your application. The company also offers a wide range of accessories for a variety of machinery. For more information, please visit the company website.

As one of the leading manufacturers of roller chains, the CZPT Company offers unparalleled expertise and wear resistance in the power transmission market. CZPT is trusted by leading industries and provides the highest return on investment. The diamond is a symbol of strength and durability, and the company chose it as the company’s trademark to convey its core values. CZPTs can last up to 100 years or more in harsh conditions, even in underwater environments.

Self-lubricating chain

Self-lubricating roller chains are designed to increase performance while maintaining a high level of cleanliness. These chains are made of sintered alloy bushings impregnated with lubricant and pins specially treated to release oil when necessary. These chains have a long service life and are suitable for environments where regular lubrication is difficult. Below are the benefits of self-lubricating roller chains.

Maintenance-free self-lubricating roller chains are the perfect replacement for standard roller chains. They are suitable for packaging, printing, textile, and sawmill applications. These chains reduce downtime and increase productivity. Furthermore, they reduce the risk of contamination. Another advantage is that there are many types of self-lubricating roller chains to choose from, allowing you to choose the one that best suits your needs. To learn more about these benefits, read the Maintenance Free Roller Chains Market Report published by Dataintelo.

CAN-AM self-lubricating roller chains ensure stick-free operation. These chains are available in ANSI/BS standard and double pitch variants. They feature oil-impregnated bushings and preloaded sintered steel bushings for long life. These self-lubricating roller chains are drop-in replacements for standard roller chains and run on standard roller chain sprockets.<br/

X-Ring and O-Ring Chains

Both O-ring and X-ring roller chains are sealed and unsealed. You’ll find them on vintage bikes and small economy cars. Other applications include bulldozer treads and conveyor belts. Standard chains are made of simple plain bearings that require lubrication every few hundred miles. While the former is the most affordable type of roller chain, they do require more maintenance than O-rings.

The main difference between the two types of chains is the friction and cost they generate. X-rings are slightly less expensive, but they create less friction than O-rings. X-rings are a more affordable option for road riders, while O-ring chains are more expensive for off-road racers. In some cases, X-ring and O-ring roller chains can be distinguished by the price tag alone.

Both X-ring and O-ring roller sprockets are available in a variety of styles. The two styles offer comparable performance, but there are some key differences to consider. X-rings are generally better for longer travel as they offer greater durability and performance. O-rings are usually more expensive than X-ring chains, but if you’re thinking about long trips, they’re a great option.

Reverse chain

Inverted roller chains are often referred to as silent chains. They have two protrusions on each board. The outer surface is ground to include an angle of sixty or seventy degrees. These protrusions about the working surfaces of the sprocket teeth. The inner surface or shape of the sprocket can clear the sprocket. This produces a silent but still valid chain. This type of chain is used in transmissions to move heavy objects.

There are three basic types of inverted toothed roller chains. Simple chains are single chains, while double and triple chains have two or three strands. In these types of chains, the pins pass through-hardened steel bushings at the ends of the links. The main difference between these types is their size. If you are not sure what size you need, first calculate the capacity of the chain. You might be surprised to learn that the smaller the diameter the better.

The number of links in a reverse roller chain determines the frequency of vibration. The frequency depends on the size of the chain and the length of the chain between the sprockets. The shorter the chain, the bigger the “pull” – the up-and-down jitter caused by the sprocket. This causes additional peak loads on the drive and shortens its life.

PEER Chain’s Heavy Duty Series Double-Stranded Roller Chains

Heavy-duty double-strand roller chains are ideal for industrial and agricultural use as they provide extra stability and strength. PEER Chains manufactures chains in various lengths and pitches and offers different accessories including sprockets and pre tensioned chains. These chains are also available in a variety of different alloys and grades. Listed below are some of the most common uses for heavy-duty double strand roller chains.

Heavy-duty PEER double-strand roller chains are available in a variety of styles and types, including the HKK NICKEL PLATED series. These chains are best suited for outdoor and mildly corrosive applications. They use a patented process to increase fatigue strength and reduce initial elongation. In addition, HKK double pitch twin-strand roller chains are lighter and less expensive than standard roller chains.