Product Description

Product Description

Industrial Drive Roller Conveyor Leaf Chain

HangZhou Vision Chain Transmission Co., Ltd. offers a wide range of leaf chains that meet ISO, BS, JS, and other industry standards. Our leaf chains are made of high-quality materials and undergo advanced heat treatment technology, ensuring durability and reliability.

Our leaf chain series include BL, AL, LL, and FL, which are designed for various applications. Whether you need a leaf chain for forklift trucks, textile machinery, drilling rigs, or any other equipment requiring vertical lifting or horizontal traction, we have the right solution for you.

At HangZhou Vision Chain Transmission Co., Ltd., we understand that every customer has unique requirements. That’s why we offer customized leaf chain services to meet your specific needs. Just let us know your requirements, and our team will provide you with a tailored solution.

Key Features:

- High-quality materials and heat treatment technology

- Meets ISO, BS, JS, and other industry standards

- Available in BL, AL, LL, and FL series

- Customized leaf chain service

- Wide range of applications

Choose HangZhou Vision Chain Transmission Co., Ltd. for reliable and efficient leaf chains that deliver exceptional performance. Contact us today to discuss your leaf chain requirements.

Product Attribute

|

Usage |

Leaf Chain ,Flyer chain |

|

Material |

Alloy/Carbon Steel |

| Application industry | Metallurgy, coal, electricity, food, chemical industry, tobacco, beverage, etc |

|

Surface Treatment |

Self-color Sand-blasted Shot-peening |

| Product Series |

AL,BL ,LL,FL,LH |

| Port |

Any sea port or airport in China |

| Brand | TV OEM |

| Payment |

L/C, T/T, D/P, Western Union |

| Package |

Chain, Plastic Bag, Color Box, Wooden Case. or OEM |

| AL Series |

AL322,AL344,AL422,AL444,AL466,AL522,AL534,AL544,AL566,AL622,AL644,AL666,AL688 AL822,AL844,AL866,AL888,AL1571,AL1044,AL1066,AL1088,AL1222,AL1244,AL1266,AL1288 AL1444,AL1466,AL1644,AL1666,AL1688 |

| BL Series | BL422,BL423,BL434,BL444,BL446,BL488,BL522,BL523,BL534,BL544,BL546,BL566,BL588

BL622,BL623,BL634,BL644,BL646,BL688,BL822,BL823,BL834,BL844,BL846,BL866,BL888 BL1571,BL1571,BL1034,BL1044,BL1046,BL1088,BL1222,BL1223,BL1234,BL1244,BL1246 BL1266,BL1288,BL1422,BL1423,BL1434,BL1444,BL1446,BL1488,BL1622,BL1623,BL1634 BL1644,BL1646,BL1666,BL1888,BL2571,BL2571,BL2034,BL2044,BL2046,BL2088 |

| LL Series | LL0622,LL0644,LL0666,LL0822,LL0844,LL0866,LL 0571 ,LL1571,LL1044,LL1066,LL1088,LL1222

LL1244,LL1266,LL1288,LL1622,LL1644,LL1666,LL1688,LL2571,LL2044,LL2066,LL2088,LL2422 LL2444,LL2466,LL2488,LL2822,LL2844,LL2866,LL2888,LL3222,LL3244,LL3266,LL3288,LL4571 LL4044,LL4066,LL4088,LL4822,LL4844,LL4866,LL4888 |

| LH Series | LH0822,LH0823,LH571,LH0844,LH0846,LH0866,LH 0571 ,LH1571,LH1571,LH1034,LH1044

LH1046,LH1066,LH1088,LH1222,LH1223,LH1234,LH1244,LH1246,LH1266,LH1288,LH1622 LH1623,LH1634,LH1644,LH1646,LH1666,LH1688,LH2571,LH2571,LH2034,LH2044,LH2046 LH2066,LH2088,LH2422,LH2423,LH2434,LH2444,LH2446,LH2466,LH2488,LH2822,LH2823 LH2834,LH2844,LH2846,LH2866,LH2888,LH3222,LH3223,LH3234,LH3244,LH3246,LH3266 LH3288,LH4571,LH4571,LH4034,LH4044,LH4046,LH4066,LH4088 |

| FL Series | FL644,FL666,FL688,FL523,FL844,FL922,FL944,FL945,FL956,FL966,FL988 |

| We also carry out OEM according to your requirements |

|

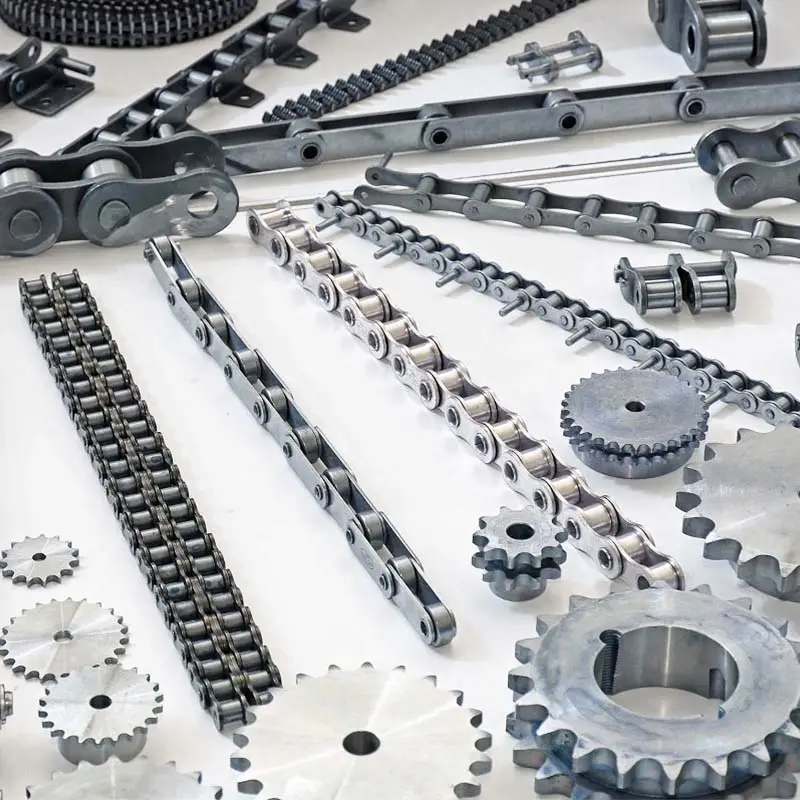

Detailed Photos

Product Parameters

Our Advantages

Company Advantages:

– Own Import & Export License

– TV trademark registered successfully in multiple countries

– Sales network covering China and exporting to 65 countries CHINAMFG

Membership:

– Member of China General Machine Components Industry Association

– Member of China Chain Transmission Association

– Member of China Chain Standardization Association

– Member of China Agricultural Association Machinery Manufacturers

With our highly trained staff and workers, advanced and efficient equipment, extensive sales network, and strict quality assurance systems, you can be confident that our premium qualified chain meets the highest standards and specifications.

Contact us now for more information on how TransVision products can fulfill your industry’s demands at competitive prices.

Quality First, Clients Uppermost.

Product Description:

HangZhou Vision Chain Transmission Co., Ltd. presents the Industrial Drive Roller Conveyor Leaf Chain Hoisting Hollow Pin Heavy Duty Stainless Steel Short Double Pitch (AL BL LL). This transmission chain is designed for various applications and is made of high-quality materials. With its durable construction and excellent performance, it ensures reliable and efficient operation.

Key Features:

– Suitable for transmission chain applications

– Made of high-quality materials

– Surface treatment: Other

Don’t miss out on the opportunity to enhance your operations with our top-notch chain. Contact us now for more information and take advantage of our competitive pricing.

HangZhou Vision Chain Transmission Co., Ltd. offers a range of industrial drive roller conveyor leaf chains. These chains are heavy-duty, stainless steel, and designed for hoisting and transmission purposes. Choose from various types, including AL, BL, and LL chains. Perfect for conveyor systems and other applications.

| WHY CHOOSE US |

Product Description

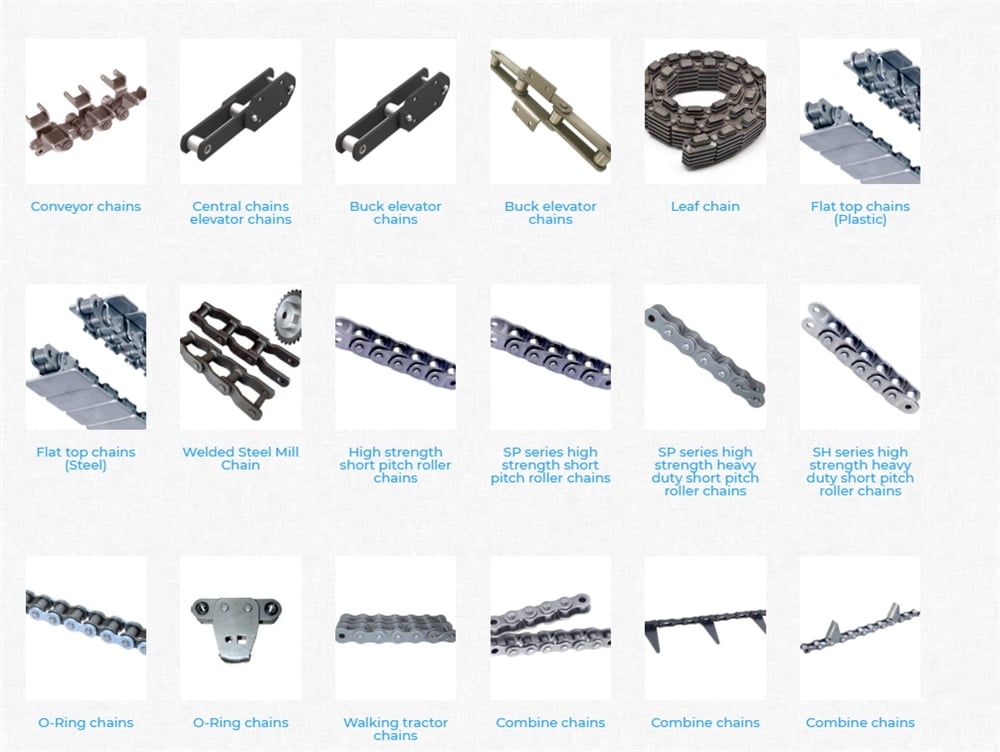

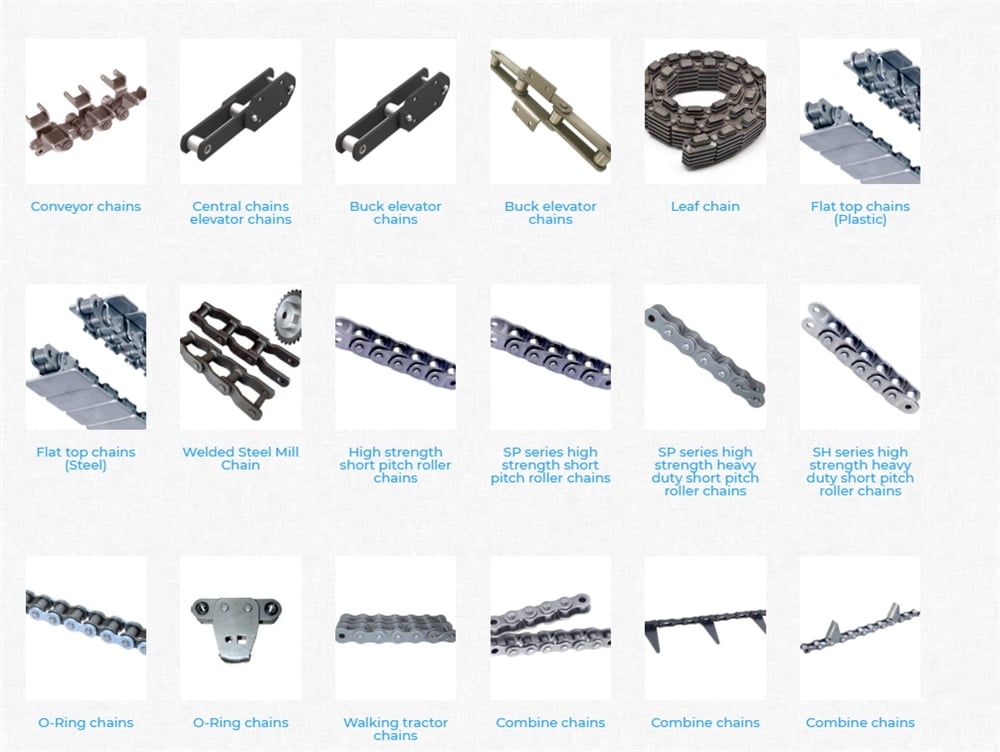

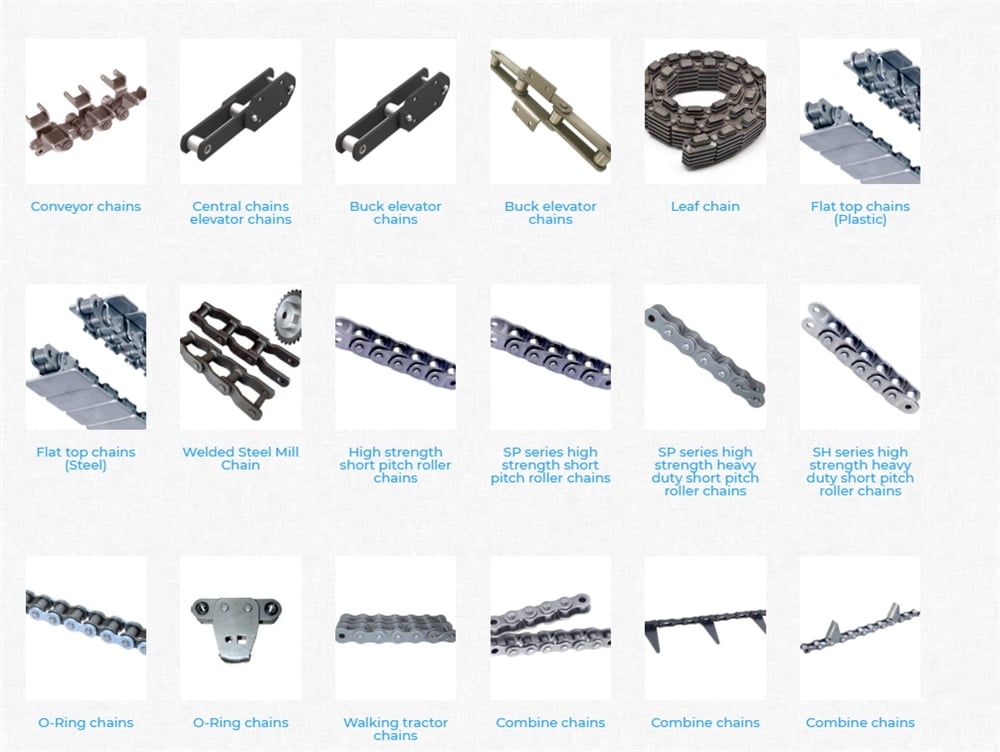

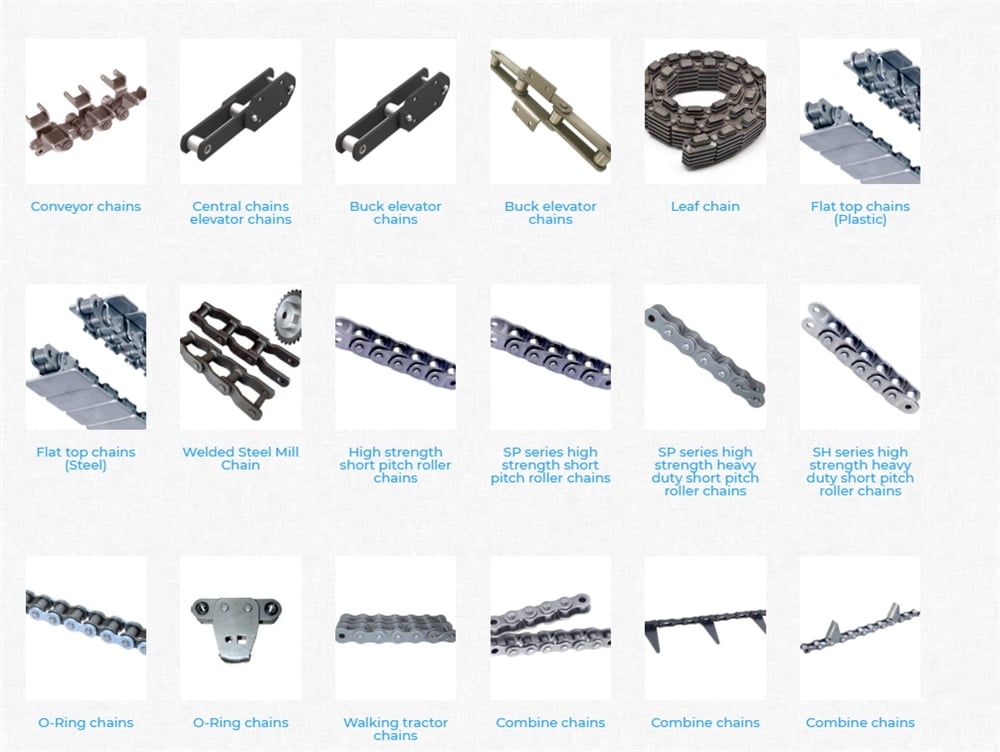

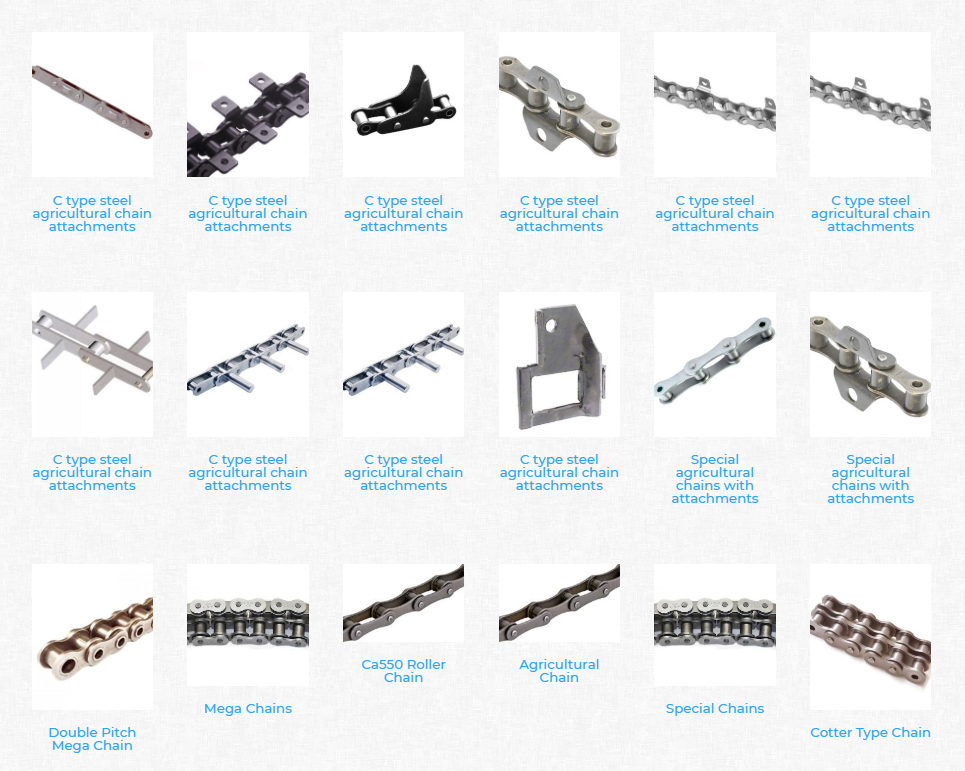

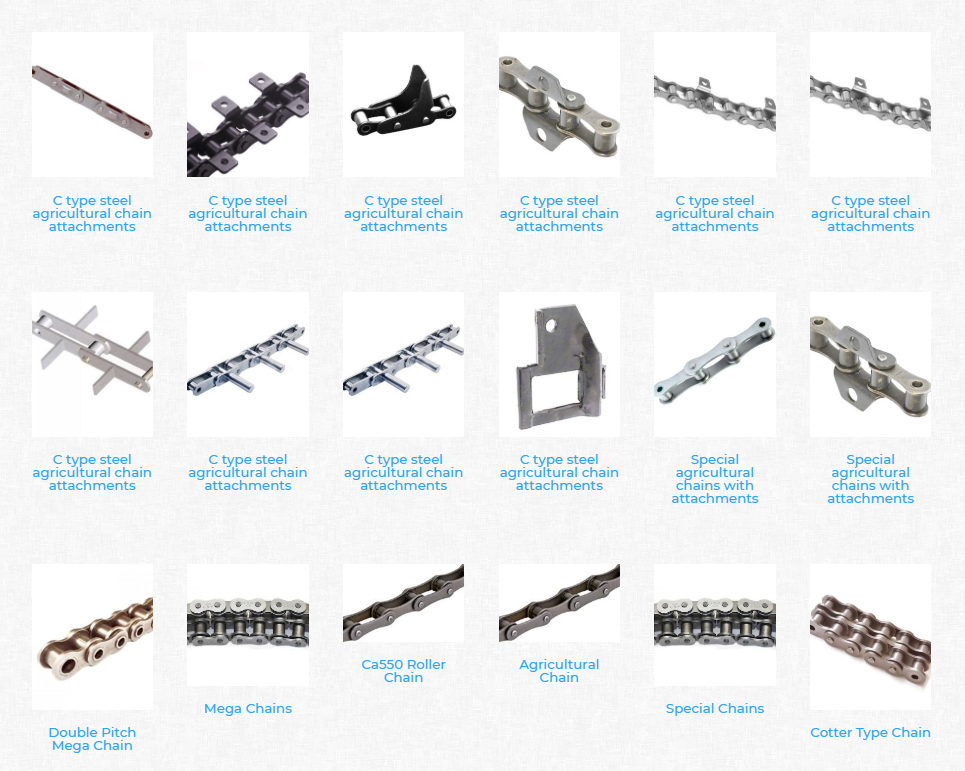

Introducing our comprehensive product portfolio from HangZhou Vision Chain Transmission Co., Ltd. We are proud to offer a wide range of power transmission products to meet all your needs. Our product lineup includes drive chains, conveyor chains, agricultural chains, sprockets, and couplings. With our one-stop shopping experience, you can easily find what you’re looking for with just 1 click, saving you time and effort.

Our products are the perfect combination of quality and affordability. We understand the importance of staying within your budget, and that’s why we offer value choice products that deliver exceptional performance without breaking the bank.

When you choose us, you’ll have the support of our seasoned sales associates and engineers. Our team consists of 15 experienced sales associates and 5 knowledgeable engineers who are always ready to lend a helping hand. With their industry know-how, they can provide you with expert advice and assistance. You can count on them to respond to your requests within 24 hours.

Our commitment to customer satisfaction is evident in our 100% customer retention rate. Our regular customers from overseas keep coming back not only for our premium quality products but also for the superior services we’ve provided over the years.

Experience the difference with HangZhou Vision Chain Transmission Co., Ltd. Choose us for all your power transmission needs and enjoy the convenience, quality, and excellent service we offer. Shop now and discover why we are the preferred choice for customers worldwide.

| FAQ |

| Q1: What’s your average lead time? A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate. Q2: Is your price better than your competitors given the same quality? Q4: Can we inspect the goods before shipment? Q5: What kind of payment method is acceptable for your mill? Q6: What if I have any other questions? |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Natural |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can an industrial chain be used in corrosive or abrasive environments?

Yes, industrial chains can be used in corrosive or abrasive environments, but the selection of the appropriate chain material and proper maintenance practices are crucial for their reliable performance. Here are some considerations:

- Corrosive Environments: In corrosive environments where the chain is exposed to chemicals, moisture, or other corrosive substances, it is essential to choose a chain material that offers excellent corrosion resistance. Stainless steel chains or chains with corrosion-resistant coatings are commonly used in such applications. These materials provide protection against rust and corrosion.

- Abrasive Environments: In abrasive environments where the chain is subjected to wear and abrasion, it is important to select a chain with high hardness and resistance to wear. Chains made from materials like alloy steel or with hardened components are suitable for such conditions. Additionally, chains with specialized surface treatments or coatings can provide extra protection against abrasion.

- Maintenance Practices: Proper maintenance is essential to extend the lifespan of an industrial chain in corrosive or abrasive environments. Regular cleaning of the chain to remove contaminants and applying appropriate lubrication can help reduce friction, wear, and corrosion. Inspecting the chain regularly for signs of damage or wear and addressing any issues promptly can also prevent premature failure.

- Considerations for Material Selection: When choosing an industrial chain for corrosive or abrasive environments, consider factors such as the specific chemicals or substances present, temperature variations, humidity levels, and the intensity of abrasion. Consulting with chain manufacturers or industry experts can help in selecting the most suitable chain material and design for your specific application.

By selecting the right chain material, implementing proper maintenance practices, and considering the specific requirements of the corrosive or abrasive environment, industrial chains can effectively operate and withstand the challenges posed by such conditions.

How does an industrial chain compare to other types of power transmission systems?

An industrial chain is a type of power transmission system that offers several advantages compared to other systems:

- Strength and durability: Industrial chains are designed to handle heavy loads and withstand tough operating conditions. They are known for their high strength and durability, making them suitable for demanding industrial applications.

- Efficiency: Industrial chains provide efficient power transmission, minimizing energy loss during operation. They offer high mechanical efficiency, which is especially important in applications that require precise and consistent power transfer.

- Flexibility: Industrial chains are flexible in terms of design and configuration. They can be easily adapted to various applications and can transmit power over long distances, making them suitable for a wide range of industrial machinery and equipment.

- Cost-effectiveness: Industrial chains are often cost-effective compared to alternative power transmission systems. They are relatively simple in design, easy to manufacture, and have a lower initial cost. Additionally, their durability and longevity reduce the need for frequent replacements, resulting in long-term cost savings.

- Reliability: Industrial chains are known for their reliability and consistent performance. When properly maintained and operated within their load and speed limits, they can provide reliable power transmission for extended periods.

- Versatility: Industrial chains can accommodate various environmental conditions, including high temperatures, corrosive environments, and high-speed applications. They can be made from different materials and configured with specific features to suit specific application requirements.

While industrial chains offer numerous advantages, it is essential to consider specific application needs and requirements when selecting a power transmission system. Factors such as load capacity, operating environment, speed, and precision may influence the suitability of an industrial chain compared to alternatives such as belts, gears, or shafts.

What lubrication is recommended for industrial chains?

Choosing the right lubrication for industrial chains is essential to ensure their smooth operation and longevity. Here are some commonly recommended lubricants for industrial chains:

- Chain Oil: Chain oils are specifically formulated for industrial chain applications. They have excellent penetration and adhesion properties, providing lubrication to the chain’s internal components. Chain oils often have anti-wear and anti-corrosion additives to protect against friction and moisture.

- Grease: Greases designed for industrial chain lubrication offer good adhesion and cling properties. They provide a protective film that stays in place even under high loads and temperatures. Greases can provide long-lasting lubrication and are suitable for applications where oil may not be suitable or accessible.

- Dry Film Lubricants: Dry film lubricants, such as PTFE (polytetrafluoroethylene) or molybdenum disulfide-based coatings, are applied as a thin film to the chain. They create a low-friction barrier between the chain components, reducing wear and enhancing performance. Dry film lubricants are particularly useful in applications where oil or grease may attract dirt, dust, or contaminants.

When selecting a lubricant for industrial chains, consider factors such as operating conditions, temperature, load, speed, and environmental conditions. It’s important to consult the chain manufacturer’s recommendations and follow their guidelines for lubrication intervals and application methods. Regular lubrication and maintenance will help reduce friction, wear, and the risk of chain failures in industrial applications.

editor by CX 2024-04-23

China supplier ISO/ANSI/DIN Standard Short Pitch Precision Stainless Steel Hardware Transmission Motorcycle Industrial Roller Chain

Product Description

ISO/ANSI/DIN Standard Short Pitch Precision Stainless Steel Hardware Transmission Motorcycle Industrial Roller Chain

Product Description

1. Material: Stainless Steel 304 & 316 / Alloy Carbon Steel

2. Surface Treatment: Shot peening / Zinc-plated / Nickel-plated / Dacromet-plated

3. Chain No:

35SS-1, 40SS-1, 50SS-1, 60SS-1, 80SS-1, 100SS-1, 120SS-1, 140SS-1;

35SS-2, 40SS-2, 50SS-2, 60SS-2, 80SS-2, 100SS-2, 120SS-2, 140SS-2;

35SS-3, 40SS-3, 50SS-3, 60SS-3, 80SS-3, 100SS-3, 120SS-3, 140SS-3;

4. Application: Stainless Steel Chains are used in so many industries, such as machine manufacturing, food machine, etc. Also are suitable for high and low temperature conditions.

5. Characteristic:

1. The chain can be used on the both sides of multi-axle transmission.

2. Easy installation and replacement.

3. It can obtain larger reduction ratio.

4. The roller chain has good elasticity, high strength and each hinge part has lubricating oil, so it can be stored easliy. Thus, compared with the rigid contact tooth, it has good cushioning and vibration absorbing ability.

| Product name | Stainless Steel Roller Chain From China |

| Materials Available | 1. Stainless Steel: SS304, SS316, etc |

| 2. Alloy Steel: 45Mn, 42CrMo, 20CrMo, etc | |

| 3. OEM according to your request | |

| Surface Treatment | Shot peening, Blackening, Oxygenation, Polishing, Zinc-plated, Nickel-plated, Anodized, etc. |

| Characteristic | Fire Resistant, Oil Resistant, Heat Resistant |

| Design criterion | ISO DIN ANSI & Customer’s Drawing |

| Size | Customer’s Drawing & ISO standard |

| Package | Wooden Case / Container and pallet, or made-to-order |

| Certificate | ISO9001: 2008 |

| Advantage | First quality, Best service, Competitive price, Fast delivery |

| Delivery Time | 20 days for samples. 45 days for official order. |

Detailed Photos

View more products,please click here…

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain |

|---|---|

| Material: | Stainless steel |

| Structure: | Roller Chain |

| 40-1: | 1/2" |

| 50-1: | 5/8" |

| 60-1: | 3/4" |

| Samples: |

US$ 0/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the benefits of using plastic industrial chains?

Plastic industrial chains offer several advantages in various applications. Here are some benefits of using plastic industrial chains:

- Corrosion resistance: Plastic chains are highly resistant to corrosion, making them suitable for use in corrosive environments where metal chains may degrade over time.

- Chemical resistance: Plastic chains can withstand exposure to a wide range of chemicals without deteriorating, making them ideal for applications in chemical processing or handling.

- Lightweight: Plastic chains are significantly lighter than their metal counterparts, reducing the overall weight of the system and allowing for easier handling and installation.

- Low noise: Plastic chains produce less noise during operation compared to metal chains, making them suitable for applications where noise reduction is important, such as in food processing or packaging.

- Self-lubricating: Some plastic chains are designed with self-lubricating properties, reducing the need for frequent lubrication and maintenance.

- High strength: Despite their lightweight nature, plastic chains can still provide high tensile strength and load-bearing capabilities, making them suitable for various heavy-duty applications.

- Low friction: Plastic chains exhibit low friction characteristics, resulting in smoother and more efficient operation, reducing power consumption and wear.

- Design flexibility: Plastic chains can be molded into various shapes and sizes, allowing for customization and adaptation to specific application requirements.

- Cost-effective: Plastic chains are often more cost-effective compared to metal chains, making them an economical choice for many industrial applications.

Plastic industrial chains offer a range of benefits, including resistance to corrosion, chemicals, and noise, lightweight design, self-lubrication, and design flexibility, making them suitable for a wide range of industries and applications.

What are the environmental considerations when using an industrial chain?

When using an industrial chain, there are several environmental considerations to take into account:

1. Lubrication: Proper lubrication of the chain is important not only for its performance but also for environmental reasons. Using environmentally-friendly lubricants can help minimize the impact on the environment, especially in applications where there is a risk of lubricant leakage or contamination.

2. Material Selection: Choosing the right materials for the chain and its components is crucial. Opting for materials that are resistant to corrosion and wear can extend the chain’s lifespan and reduce the need for frequent replacements, thus minimizing waste.

3. Maintenance and Inspection: Regular maintenance and inspection of the chain can help identify any potential issues early on, preventing unexpected failures and reducing the environmental impact of unplanned downtime and repairs.

4. Noise and Vibration: Industrial chains can generate noise and vibrations during operation, which may have environmental implications, especially in noise-sensitive areas or where worker comfort is a priority. Implementing measures to minimize noise and vibration, such as proper lubrication, chain tensioning, and damping systems, can help mitigate these effects.

5. Waste Management: Proper disposal and recycling of worn-out or damaged chain components are important to minimize the environmental impact. Recycling programs or partnering with responsible waste management companies can ensure that discarded chain components are properly handled and disposed of in an environmentally friendly manner.

By considering these environmental factors and implementing appropriate measures, the use of industrial chains can be made more sustainable and environmentally responsible.

What are the different types of industrial chains?

Industrial chains are available in various types, each designed to suit specific applications and requirements. Here are some common types of industrial chains:

- Roller chains: Roller chains are the most common type of industrial chains. They consist of a series of interconnected rollers that engage with the sprockets to transmit power and facilitate the movement of materials.

- Conveyor chains: Conveyor chains are specifically designed for use in conveyor systems. They have attachments or slats that allow them to carry materials or products along a horizontal or inclined path.

- Leaf chains: Leaf chains are made up of interlocking plates or links that provide high tensile strength and resistance to fatigue. They are commonly used in applications that require heavy lifting or load-bearing capabilities.

- Wire mesh chains: Wire mesh chains are composed of interconnected wire mesh links. They are often used in applications that involve high-temperature environments, such as oven conveyors or drying processes.

- Bucket elevator chains: Bucket elevator chains are designed for vertical lifting applications, typically used in industries such as agriculture, mining, and construction. They feature buckets that carry materials as they move upward.

- Precision chains: Precision chains are engineered to provide precise positioning and accurate movement. They are commonly used in applications such as robotics, automation, and CNC machinery.

- Specialty chains: Specialty chains are designed for specific applications and industries. Examples include agricultural chains, escalator chains, drag chains, and many more.

Each type of industrial chain has its unique design features, materials, and applications. The selection of the appropriate chain type depends on factors such as load capacity, speed, environment, and specific operational requirements.

editor by CX 2024-04-15

China supplier Factory OEM ODM Customized and Standard Stainless Steel Material Roller Chain/Agriculture Chain/Industrial Chain

Product Description

| Chain No | Pitch | Width Between Inner Plates |

Pin Dia |

Pin Length |

Inner Plate Depth |

Average Tensile Strength |

Weight |

| Mm | mm | mm | mm | mm | mm | Kn | kg/m |

| 04B-1 | 6.000 | 2.80 | 1.85 | 6.80 | 5.00 | 3.2 | 0.11 |

| 05B-1 | 8.000 | 3.00 | 2.31 | 8.20 | 7.10 | 5.9 | 0.20 |

| *06B-1 | 9.525 | 5.72 | 3.28 | 13.15 | 8.20 | 10.4 | 0.41 |

| 08B-1 | 12.700 | 7.75 | 4.45 | 16.70 | 11.80 | 19.40 | 0.69 |

| 10B-1 | 15.875 | 9.65 | 5.09 | 19.50 | 14.70 | 27.50 | 0.93 |

| 12B-1 | 19.050 | 11.68 | 5.72 | 22.50 | 16.00 | 32.20 | 1.15 |

| 16B-1 | 25.400 | 17.02 | 8.28 | 36.10 | 21.00 | 72.80 | 2.71 |

| 20B-1 | 31.750 | 19.56 | 10.19 | 41.30 | 26.40 | 106.7 | 3.70 |

| 24B-1 | 38.100 | 25.40 | 14.63 | 53.40 | 33.20 | 178.0 | 7.10 |

| 28B-1 | 44.450 | 30.99 | 15.90 | 65.10 | 36.70 | 222.0 | 8.50 |

| 32B-1 | 50.800 | 30.99 | 17.81 | 66.00 | 42.00 | 277.5 | 10.25 |

| 40B-1 | 63.50 | 38.10 | 22.89 | 82.20 | 52.96 | 394.0 | 16.35 |

| 48B-1 | 76.20 | 45.72 | 29.24 | 99.10 | 63.80 | 621.6 | 25.00 |

| 56B-1 | 88.90 | 53.34 | 34.32 | 114.60 | 77.80 | 940.0 | 35.78 |

Our company offers variety of products which can meet your multifarious demands. We adhere to the management principles of “quality first, customer first and credit-based” since the establishment of the company and always do our best to satisfy potential needs of our customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a CHINAMFG situation since the trend of economic globalization has developed with anirresistible force.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Food Machinery |

| Structure: | Roller Chain |

| Material: | Stainless Steel |

| Type: | Double Pitch Chain |

| Tensile Strength: | High |

| Customization: |

Available

| Customized Request |

|---|

What are the factors to consider when selecting the pitch of an industrial chain?

The pitch of an industrial chain refers to the distance between adjacent pins or rollers on the chain. When selecting the pitch of an industrial chain, several factors should be considered:

- Load requirements: The pitch of the chain should be selected based on the expected load that the chain will need to carry. Higher loads typically require larger pitch sizes to ensure sufficient strength and durability.

- Speed of operation: The chain’s pitch should be chosen based on the speed at which the chain will be operating. Higher speeds may require smaller pitch sizes to maintain smooth and efficient operation.

- Space limitations: The available space for the chain system should be considered when selecting the pitch. Smaller pitch sizes can accommodate tighter spaces, while larger pitch sizes may be suitable for applications with more ample space.

- Application requirements: The specific requirements of the application should be taken into account. Factors such as the type of load being transported, the operating environment (temperature, moisture, etc.), and any special considerations (e.g., noise reduction, corrosion resistance) can influence the pitch selection.

- Chain compatibility: It is essential to ensure that the selected chain pitch is compatible with the sprockets or gears used in the system. The chain and sprocket/gear pitch should match to ensure proper engagement and efficient power transmission.

- Service life expectations: Consideration should be given to the desired service life of the chain. In applications with high-cycle operations or demanding conditions, selecting a chain with a smaller pitch size or a specialized design may be necessary to enhance longevity.

By carefully considering the load requirements, speed of operation, space limitations, application requirements, chain compatibility, and service life expectations, one can select the appropriate pitch size for an industrial chain that ensures optimal performance and reliability.

What are the common causes of industrial chain failures?

Industrial chain failures can occur due to various factors:

- Excessive load: Applying a load that exceeds the chain’s capacity can lead to stress and failure. It is important to consider the chain’s rated load and choose the appropriate chain for the application.

- Inadequate lubrication: Insufficient or improper lubrication can result in increased friction and wear, leading to premature chain failure. Regular lubrication with the recommended lubricant and following the manufacturer’s guidelines is crucial.

- Improper tensioning: Incorrect chain tension can cause misalignment, premature wear, and failure. Proper tensioning ensures optimal performance and longevity of the chain.

- Misalignment: Poor alignment between the sprockets can cause the chain to wear unevenly and increase the risk of failure. Proper alignment of the sprockets is essential for smooth operation.

- Wear and tear: Continuous use without proper maintenance and regular inspection can result in chain fatigue, elongation, and eventual failure. Regular inspection and timely replacement of worn-out components are necessary to prevent failure.

- Corrosion: Exposure to corrosive environments can weaken the chain material and compromise its integrity. Using corrosion-resistant chains or applying appropriate coatings can mitigate the risk of corrosion-related failures.

- Lack of maintenance: Neglecting routine maintenance tasks such as cleaning, lubrication, and inspection can lead to chain degradation and eventual failure. Regular maintenance is essential to ensure optimal chain performance and longevity.

What are the different types of industrial chains?

Industrial chains are available in various types, each designed to suit specific applications and requirements. Here are some common types of industrial chains:

- Roller chains: Roller chains are the most common type of industrial chains. They consist of a series of interconnected rollers that engage with the sprockets to transmit power and facilitate the movement of materials.

- Conveyor chains: Conveyor chains are specifically designed for use in conveyor systems. They have attachments or slats that allow them to carry materials or products along a horizontal or inclined path.

- Leaf chains: Leaf chains are made up of interlocking plates or links that provide high tensile strength and resistance to fatigue. They are commonly used in applications that require heavy lifting or load-bearing capabilities.

- Wire mesh chains: Wire mesh chains are composed of interconnected wire mesh links. They are often used in applications that involve high-temperature environments, such as oven conveyors or drying processes.

- Bucket elevator chains: Bucket elevator chains are designed for vertical lifting applications, typically used in industries such as agriculture, mining, and construction. They feature buckets that carry materials as they move upward.

- Precision chains: Precision chains are engineered to provide precise positioning and accurate movement. They are commonly used in applications such as robotics, automation, and CNC machinery.

- Specialty chains: Specialty chains are designed for specific applications and industries. Examples include agricultural chains, escalator chains, drag chains, and many more.

Each type of industrial chain has its unique design features, materials, and applications. The selection of the appropriate chain type depends on factors such as load capacity, speed, environment, and specific operational requirements.

editor by CX 2024-04-10

China supplier Industrial Transmission Roller Chain for Coal Machine and Car Parking

Product Description

ROLLER CHAIN

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient means of power transmission.

CONSTRUCTION OF THE CHAIN

Two different sizes of roller chain, showing construction.

There are 2 types of links alternating in the bush roller chain. The first type is inner links, having 2 inner plates held together by 2 sleeves or bushings CHINAMFG which rotate 2 rollers. Inner links alternate with the second type, the outer links, consisting of 2 outer plates held together by pins passing through the bushings of the inner links. The “bushingless” roller chain is similar in operation though not in construction; instead of separate bushings or sleeves holding the inner plates together, the plate has a tube stamped into it protruding from the hole which serves the same purpose. This has the advantage of removing 1 step in assembly of the chain.

The roller chain design reduces friction compared to simpler designs, resulting in higher efficiency and less wear. The original power transmission chain varieties lacked rollers and bushings, with both the inner and outer plates held by pins which directly contacted the sprocket teeth; however this configuration exhibited extremely rapid wear of both the sprocket teeth, and the plates where they pivoted on the pins. This problem was partially solved by the development of bushed chains, with the pins holding the outer plates passing through bushings or sleeves connecting the inner plates. This distributed the wear over a greater area; however the teeth of the sprockets still wore more rapidly than is desirable, from the sliding friction against the bushings. The addition of rollers surrounding the bushing sleeves of the chain and provided rolling contact with the teeth of the sprockets resulting in excellent resistance to wear of both sprockets and chain as well. There is even very low friction, as long as the chain is sufficiently lubricated. Continuous, clean, lubrication of roller chains is of primary importance for efficient operation as well as correct tensioning.

LUBRICATION

Many driving chains (for example, in factory equipment, or driving a camshaft inside an internal combustion engine) operate in clean environments, and thus the wearing surfaces (that is, the pins and bushings) are safe from precipitation and airborne grit, many even in a sealed environment such as an oil bath. Some roller chains are designed to have o-rings built into the space between the outside link plate and the inside roller link plates. Chain manufacturers began to include this feature in 1971 after the application was invented by Joseph Montano while working for Whitney Chain of Hartford, Connecticut. O-rings were included as a way to improve lubrication to the links of power transmission chains, a service that is vitally important to extending their working life. These rubber fixtures form a barrier that holds factory applied lubricating grease inside the pin and bushing wear areas. Further, the rubber o-rings prevent dirt and other contaminants from entering inside the chain linkages, where such particles would otherwise cause significant wear.[citation needed]

There are also many chains that have to operate in dirty conditions, and for size or operational reasons cannot be sealed. Examples include chains on farm equipment, bicycles, and chain saws. These chains will necessarily have relatively high rates of wear, particularly when the operators are prepared to accept more friction, less efficiency, more noise and more frequent replacement as they neglect lubrication and adjustment.

Many oil-based lubricants attract dirt and other particles, eventually forming an CHINAMFG paste that will compound wear on chains. This problem can be circumvented by use of a “dry” PTFE spray, which forms a solid film after application and repels both particles and moisture.

VARIANTS DESIGN

Layout of a roller chain: 1. Outer plate, 2. Inner plate, 3. Pin, 4. Bushing, 5. Roller

If the chain is not being used for a high wear application (for instance if it is just transmitting motion from a hand-operated lever to a control shaft on a machine, or a sliding door on an oven), then 1 of the simpler types of chain may still be used. Conversely, where extra strength but the smooth drive of a smaller pitch is required, the chain may be “siamesed”; instead of just 2 rows of plates on the outer sides of the chain, there may be 3 (“duplex”), 4 (“triplex”), or more rows of plates running parallel, with bushings and rollers between each adjacent pair, and the same number of rows of teeth running in parallel on the sprockets to match. Timing chains on automotive engines, for example, typically have multiple rows of plates called strands.

Roller chain is made in several sizes, the most common American National Standards Institute (ANSI) standards being 40, 50, 60, and 80. The first digit(s) indicate the pitch of the chain in eighths of an inch, with the last digit being 0 for standard chain, 1 for lightweight chain, and 5 for bushed chain with no rollers. Thus, a chain with half-inch pitch would be a #40 while a #160 sprocket would have teeth spaced 2 inches apart, etc. Metric pitches are expressed in sixteenths of an inch; thus a metric #8 chain (08B-1) would be equivalent to an ANSI #40. Most roller chain is made from plain carbon or alloy steel, but stainless steel is used in food processing machinery or other places where lubrication is a problem, and nylon or brass are occasionally seen for the same reason.

Roller chain is ordinarily hooked up using a master link (also known as a connecting link), which typically has 1 pin held by a horseshoe clip rather than friction fit, allowing it to be inserted or removed with simple tools. Chain with a removable link or pin is also known as cottered chain, which allows the length of the chain to be adjusted. Half links (also known as offsets) are available and are used to increase the length of the chain by a single roller. Riveted roller chain has the master link (also known as a connecting link) “riveted” or mashed on the ends. These pins are made to be durable and are not removable.

USE

An example of 2 ‘ghost’ sprockets tensioning a triplex roller chain system

Roller chains are used in low- to mid-speed drives at around 600 to 800 feet per minute; however, at higher speeds, around 2,000 to 3,000 feet per minute, V-belts are normally used due to wear and noise issues.

A bicycle chain is a form of roller chain. Bicycle chains may have a master link, or may require a chain tool for removal and installation. A similar but larger and thus stronger chain is used on most motorcycles although it is sometimes replaced by either a toothed belt or a shaft drive, which offer lower noise level and fewer maintenance requirements.

The great majority of automobile engines use roller chains to drive the camshaft(s). Very high performance engines often use gear drive, and starting in the early 1960s toothed belts were used by some manufacturers.

Chains are also used in forklifts using hydraulic rams as a pulley to raise and lower the carriage; however, these chains are not considered roller chains, but are classified as lift or leaf chains.

Chainsaw cutting chains superficially resemble roller chains but are more closely related to leaf chains. They are driven by projecting drive links which also serve to locate the chain CHINAMFG the bar.

Sea Harrier FA.2 ZA195 front (cold) vector thrust nozzle – the nozzle is rotated by a chain drive from an air motor

A perhaps unusual use of a pair of motorcycle chains is in the Harrier Jump Jet, where a chain drive from an air motor is used to rotate the movable engine nozzles, allowing them to be pointed downwards for hovering flight, or to the rear for normal CHINAMFG flight, a system known as Thrust vectoring.

WEAR

The effect of wear on a roller chain is to increase the pitch (spacing of the links), causing the chain to grow longer. Note that this is due to wear at the pivoting pins and bushes, not from actual stretching of the metal (as does happen to some flexible steel components such as the hand-brake cable of a motor vehicle).

With modern chains it is unusual for a chain (other than that of a bicycle) to wear until it breaks, since a worn chain leads to the rapid onset of wear on the teeth of the sprockets, with ultimate failure being the loss of all the teeth on the sprocket. The sprockets (in particular the smaller of the two) suffer a grinding motion that puts a characteristic hook shape into the driven face of the teeth. (This effect is made worse by a chain improperly tensioned, but is unavoidable no matter what care is taken). The worn teeth (and chain) no longer provides smooth transmission of power and this may become evident from the noise, the vibration or (in car engines using a timing chain) the variation in ignition timing seen with a timing light. Both sprockets and chain should be replaced in these cases, since a new chain on worn sprockets will not last long. However, in less severe cases it may be possible to save the larger of the 2 sprockets, since it is always the smaller 1 that suffers the most wear. Only in very light-weight applications such as a bicycle, or in extreme cases of improper tension, will the chain normally jump off the sprockets.

The lengthening due to wear of a chain is calculated by the following formula:

M = the length of a number of links measured

S = the number of links measured

P = Pitch

In industry, it is usual to monitor the movement of the chain tensioner (whether manual or automatic) or the exact length of a drive chain (one rule of thumb is to replace a roller chain which has elongated 3% on an adjustable drive or 1.5% on a fixed-center drive). A simpler method, particularly suitable for the cycle or motorcycle user, is to attempt to pull the chain away from the larger of the 2 sprockets, whilst ensuring the chain is taut. Any significant movement (e.g. making it possible to see through a gap) probably indicates a chain worn up to and beyond the limit. Sprocket damage will result if the problem is ignored. Sprocket wear cancels this effect, and may mask chain wear.

CHAIN STRENGTH

The most common measure of roller chain’s strength is tensile strength. Tensile strength represents how much load a chain can withstand under a one-time load before breaking. Just as important as tensile strength is a chain’s fatigue strength. The critical factors in a chain’s fatigue strength is the quality of steel used to manufacture the chain, the heat treatment of the chain components, the quality of the pitch hole fabrication of the linkplates, and the type of shot plus the intensity of shot peen coverage on the linkplates. Other factors can include the thickness of the linkplates and the design (contour) of the linkplates. The rule of thumb for roller chain operating on a continuous drive is for the chain load to not exceed a mere 1/6 or 1/9 of the chain’s tensile strength, depending on the type of master links used (press-fit vs. slip-fit)[citation needed]. Roller chains operating on a continuous drive beyond these thresholds can and typically do fail prematurely via linkplate fatigue failure.

The standard minimum ultimate strength of the ANSI 29.1 steel chain is 12,500 x (pitch, in inches)2. X-ring and O-Ring chains greatly decrease wear by means of internal lubricants, increasing chain life. The internal lubrication is inserted by means of a vacuum when riveting the chain together.

CHAIN STHangZhouRDS

Standards organizations (such as ANSI and ISO) maintain standards for design, dimensions, and interchangeability of transmission chains. For example, the following Table shows data from ANSI standard B29.1-2011 (Precision Power Transmission Roller Chains, Attachments, and Sprockets) developed by the American Society of Mechanical Engineers (ASME). See the references[8][9][10] for additional information.

ASME/ANSI B29.1-2011 Roller Chain Standard SizesSizePitchMaximum Roller DiameterMinimum Ultimate Tensile StrengthMeasuring Load25

| ASME/ANSI B29.1-2011 Roller Chain Standard Sizes | ||||

| Size | Pitch | Maximum Roller Diameter | Minimum Ultimate Tensile Strength | Measuring Load |

|---|---|---|---|---|

| 25 | 0.250 in (6.35 mm) | 0.130 in (3.30 mm) | 780 lb (350 kg) | 18 lb (8.2 kg) |

| 35 | 0.375 in (9.53 mm) | 0.200 in (5.08 mm) | 1,760 lb (800 kg) | 18 lb (8.2 kg) |

| 41 | 0.500 in (12.70 mm) | 0.306 in (7.77 mm) | 1,500 lb (680 kg) | 18 lb (8.2 kg) |

| 40 | 0.500 in (12.70 mm) | 0.312 in (7.92 mm) | 3,125 lb (1,417 kg) | 31 lb (14 kg) |

| 50 | 0.625 in (15.88 mm) | 0.400 in (10.16 mm) | 4,880 lb (2,210 kg) | 49 lb (22 kg) |

| 60 | 0.750 in (19.05 mm) | 0.469 in (11.91 mm) | 7,030 lb (3,190 kg) | 70 lb (32 kg) |

| 80 | 1.000 in (25.40 mm) | 0.625 in (15.88 mm) | 12,500 lb (5,700 kg) | 125 lb (57 kg) |

| 100 | 1.250 in (31.75 mm) | 0.750 in (19.05 mm) | 19,531 lb (8,859 kg) | 195 lb (88 kg) |

| 120 | 1.500 in (38.10 mm) | 0.875 in (22.23 mm) | 28,125 lb (12,757 kg) | 281 lb (127 kg) |

| 140 | 1.750 in (44.45 mm) | 1.000 in (25.40 mm) | 38,280 lb (17,360 kg) | 383 lb (174 kg) |

| 160 | 2.000 in (50.80 mm) | 1.125 in (28.58 mm) | 50,000 lb (23,000 kg) | 500 lb (230 kg) |

| 180 | 2.250 in (57.15 mm) | 1.460 in (37.08 mm) | 63,280 lb (28,700 kg) | 633 lb (287 kg) |

| 200 | 2.500 in (63.50 mm) | 1.562 in (39.67 mm) | 78,175 lb (35,460 kg) | 781 lb (354 kg) |

| 240 | 3.000 in (76.20 mm) | 1.875 in (47.63 mm) | 112,500 lb (51,000 kg) | 1,000 lb (450 kg |

For mnemonic purposes, below is another presentation of key dimensions from the same standard, expressed in fractions of an inch (which was part of the thinking behind the choice of preferred numbers in the ANSI standard):

| Pitch (inches) | Pitch expressed in eighths |

ANSI standard chain number |

Width (inches) |

|---|---|---|---|

| 1⁄4 | 2⁄8 | 25 | 1⁄8 |

| 3⁄8 | 3⁄8 | 35 | 3⁄16 |

| 1⁄2 | 4⁄8 | 41 | 1⁄4 |

| 1⁄2 | 4⁄8 | 40 | 5⁄16 |

| 5⁄8 | 5⁄8 | 50 | 3⁄8 |

| 3⁄4 | 6⁄8 | 60 | 1⁄2 |

| 1 | 8⁄8 | 80 | 5⁄8 |

Notes:

1. The pitch is the distance between roller centers. The width is the distance between the link plates (i.e. slightly more than the roller width to allow for clearance).

2. The right-hand digit of the standard denotes 0 = normal chain, 1 = lightweight chain, 5 = rollerless bushing chain.

3. The left-hand digit denotes the number of eighths of an inch that make up the pitch.

4. An “H” following the standard number denotes heavyweight chain. A hyphenated number following the standard number denotes double-strand (2), triple-strand (3), and so on. Thus 60H-3 denotes number 60 heavyweight triple-strand chain.

A typical bicycle chain (for derailleur gears) uses narrow 1⁄2-inch-pitch chain. The width of the chain is variable, and does not affect the load capacity. The more sprockets at the rear wheel (historically 3-6, nowadays 7-12 sprockets), the narrower the chain. Chains are sold according to the number of speeds they are designed to work with, for example, “10 speed chain”. Hub gear or single speed bicycles use 1/2″ x 1/8″ chains, where 1/8″ refers to the maximum thickness of a sprocket that can be used with the chain.

Typically chains with parallel shaped links have an even number of links, with each narrow link followed by a broad one. Chains built up with a uniform type of link, narrow at 1 and broad at the other end, can be made with an odd number of links, which can be an advantage to adapt to a special chainwheel-distance; on the other side such a chain tends to be not so strong.

Roller chains made using ISO standard are sometimes called as isochains.

WHY CHOOSE US

1. Reliable Quality Assurance System

2. Cutting-Edge Computer-Controlled CNC Machines

3. Bespoke Solutions from Highly Experienced Specialists

4. Customization and OEM Available for Specific Application

5. Extensive Inventory of Spare Parts and Accessories

6. Well-Developed CHINAMFG Marketing Network

7. Efficient After-Sale Service System

The 219 sets of advanced automatic production equipment provide guarantees for high product quality. The 167 engineers and technicians with senior professional titles can design and develop products to meet the exact demands of customers, and OEM customizations are also available with us. Our sound global service network can provide customers with timely after-sales technical services.

We are not just a manufacturer and supplier, but also an industry consultant. We work pro-actively with you to offer expert advice and product recommendations in order to end up with a most cost effective product available for your specific application. The clients we serve CHINAMFG range from end users to distributors and OEMs. Our OEM replacements can be substituted wherever necessary and suitable for both repair and new assemblies.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain, Drag Chain, Conveyor Chain, Dedicated Special Chain |

|---|---|

| Material: | Alloy |

| Surface Treatment: | Polishing |

| Feature: | Heat Resistant |

| Chain Size: | Roller Chains |

| Structure: | Roller Chain |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the best practices for storing and handling industrial chains?

Storing and handling industrial chains properly is essential to maintain their performance, prevent damage, and ensure safe operation. Here are some best practices to follow:

- Proper Storage: Store industrial chains in a clean, dry, and well-ventilated area to protect them from moisture, dust, and corrosive elements. Use designated storage racks or containers to keep them organized and prevent tangling or entanglement with other objects.

- Protection from Contamination: Keep industrial chains away from chemicals, solvents, and other substances that may cause corrosion or degradation. If necessary, use protective covers or coatings to shield the chains from environmental contaminants.

- Regular Inspection: Perform regular visual inspections of the chains for signs of damage, wear, or misalignment. Check for bent or damaged links, worn-out rollers or sprockets, and any abnormal wear patterns. Address any issues promptly to prevent further damage or failure.

- Proper Handling Techniques: When handling industrial chains, use appropriate lifting equipment or tools to avoid excessive bending or twisting. Avoid dropping or impacting the chains, as it can cause deformation or damage to the links.

- Correct Installation: Follow the manufacturer’s guidelines and recommended procedures for installing industrial chains. Ensure proper alignment of sprockets, correct tensioning, and appropriate lubrication to optimize performance and prevent premature wear.

- Regular Lubrication: Apply the recommended lubricant to the industrial chains according to the manufacturer’s specifications. Proper lubrication reduces friction, wear, and noise, and helps extend the chain’s lifespan.

- Training and Safety: Provide proper training to personnel involved in handling industrial chains. Ensure they understand the safety procedures, including wearing appropriate personal protective equipment and following safe work practices.

By following these best practices for storing and handling industrial chains, you can prolong their lifespan, maintain their performance, and ensure safe and reliable operation in your industrial applications.

What is the load capacity of an industrial chain?

An industrial chain’s load capacity refers to the maximum amount of weight or force it can safely withstand without experiencing failure or damage. The load capacity of an industrial chain depends on several factors, including its design, construction, material, and size.

Industrial chains are engineered and manufactured to handle a wide range of load capacities, from light-duty applications to heavy-duty industrial operations. The load capacity of a specific industrial chain is typically provided by the manufacturer and can be found in product specifications or technical documentation.

The load capacity of an industrial chain is influenced by various factors, such as:

- Chain Type and Size: Different chain types, such as roller chains, silent chains, or engineering steel chains, have varying load capacities. Additionally, the size or pitch of the chain also affects its load capacity, with larger chains generally having higher load capacities.

- Chain Material and Construction: The material used to construct the chain, such as stainless steel, carbon steel, or alloy steel, affects its strength and load-bearing capacity. The chain’s construction, including the number and arrangement of links, also plays a role in determining its load capacity.

- Operating Conditions: The environment in which the industrial chain operates, such as temperature, humidity, and exposure to chemicals or corrosive substances, can impact its load capacity. Extreme conditions may require special chains with higher load ratings.

- Application Requirements: The specific application and the forces involved, such as tension, shock loads, or dynamic forces, need to be considered when determining the appropriate load capacity of an industrial chain.

To ensure the safe and efficient operation of an industrial chain, it is crucial to select a chain with an appropriate load capacity for the intended application. Exceeding the recommended load capacity can lead to premature wear, chain failure, or safety hazards. Consulting the manufacturer’s specifications and guidelines, as well as engineering calculations, can help determine the suitable load capacity for a given industrial chain.

How does an industrial chain work in a manufacturing process?

An industrial chain plays a crucial role in a manufacturing process by facilitating the movement of materials or products along a predetermined path. Here’s a detailed explanation of how an industrial chain works:

- Input of materials: The manufacturing process begins with the input of raw materials or components onto the industrial chain. These materials are usually placed onto the chain manually or through automated systems.

- Chain movement: The industrial chain is set into motion, either by a motor or by connecting it to a power source. As the chain moves, it carries the materials or products along its path.

- Transfer and handling: The materials or products are transferred from one workstation to another as they move along the industrial chain. This transfer can involve various processes such as assembly, inspection, packaging, or any other manufacturing operation.

- Control and synchronization: The movement of the industrial chain is controlled and synchronized to ensure proper timing and coordination of the manufacturing process. This can be achieved through the use of sensors, actuators, and control systems that monitor and adjust the speed, direction, and position of the chain.

- Output and completion: As the materials or products reach the end of the industrial chain, they are either ready for further processing or considered as finished goods. They are then removed from the chain and directed to the next stage of the manufacturing process or prepared for shipment.

The working principle of an industrial chain involves the continuous loop movement of the chain, which allows for the smooth and controlled transfer of materials or products. The chain’s design, including the type of links, pitch, and attachments, is optimized to meet the specific requirements of the manufacturing process, such as load capacity, speed, and environmental conditions.

By utilizing an industrial chain in a manufacturing process, companies can achieve increased efficiency, improved productivity, and enhanced automation. The precise and reliable movement of materials or products provided by the industrial chain ensures a streamlined and synchronized manufacturing operation.

editor by CX 2024-01-05

China supplier Agricultural Rice Conveyor Roller Chain Transmission Chain with X348 X458 X678

Product Description

About Factory

With more than 18 years’ histiory, we are a professinal manufacturer for drop forged products such as forged chain (X348 X458 X658 X678 X698 F100 F160), scraper chain (10160, 14218, 14226, 142N), conveyor trolley (X348, X458, X678, XT160), and drive chain (X348, X458, X678), and so forth standard moulds of chain.

Besides, we can also produce as per your drawing or sample, special link chain, pusher, pin and plate, according to customers’ unique requirements.

Product Description

1) Material: Alloy steel, 40Cr, 42CrMo and so on.

2) Types: Standard types, X348 X458 X678, and so on. (Or as per your drawing)

3) Process: Moulding→Forging→Polishing & Blasting→Fine machining→Heat treatment→Blasting→Inspecting & testing→Packing

Product Show

Technical Data

| Model | Dimension | Weight (Kg) | Material | Hardness | Working Load (KN) | Limit Load (KN) | ||||||

| P | T | C | S | F | R | D | ||||||

| 10160B | 101.6 | 24 | 36 | 13 | 14 | 6 | 14 | 0.32 | 20CrMnTi | Surface HRC56-64° Depth 0.6-1.2mm |

18 | 100 |

| 10160 | 101.6 | 30 | 36 | 13 | 14.5 | 9 | 14 | 0.36 | 20CrMnTi | Surface HRC56-64° Depth 0.6-1.2mm | 21.6 | 120 |

| 14218 | 142 | 42 | 50 | 19 | 20.5 | 11 | 25 | 1.15 | 20CrMnTi | Surface HRC56-64° Depth 0.6-1.2mm | 48.6 | 270 |

| 14226 | 142 | 62 | 50 | 28 | 30 | 15 | 25 | 1.75 | 20CrMnTi | Surface HRC56-64° Depth 0.6-1.2mm | 61.2 | 340 |

| 2571 | 200 | 66 | 60 | 30 | 32 | 18 | 30 | 2.8 | 20CrMnTi | Surface HRC56-64° Depth 0.6-1.2mm | 72 | 400 |

| 26014 | 260 | 70 | 75 | 31 | 33 | 20 | 34 | 5.2 | 20CrMnTi | Surface HRC56-64° Depth 0.6-1.2mm | 135 | 750 |

| 142N | 142 | 43 | 50 | 19 | 22 | 12.5 | 25 | 1.2 | 40Cr | Quench HRC36-44° | 75.6 | 420 |

| 150D | 142 | 42 | 50 | 19 | 20.5 | 11 | 25 | 1.15 | 40Cr | Quench HRC36-44° | 75.6 | 420 |

| MG20 | 200 | 70 | 50 | 27 | 29 | 17 | 35 | 3.78 | 40Cr | Quench HRC36-44° | 144 | 800 |

| MG20B | 200 | 70 | 50 | 27 | 29 | 17 | 30 | 3.82 | 40Cr | Quench HRC36-44° | 140.4 | 780 |

| MG20C | 200 | 70 | 50 | 27 | 29 | 17 | 28 | 3.85 | 40Cr | Quench HRC36-44° | 122.4 | 680 |

| MS32 | 200 | 42 | 50 | 20 | 22 | 12 | 25 | 1.4 | 40Cr | Quench HRC36-44° | 75.6 | 420 |

| MS55 | 200 | 80 | 70 | 35 | 38 | 25 | 28 | 4.36 | 40Cr | Quench HRC36-44° | 138.6 | 770 |

| 3006 | 200 | 65 | 70 | 30 | 33 | 24 | 32 | 3.6 | 40Cr | Quench HRC36-44° | 160.2 | 890 |

| MS63 | 250 | 70 | 80 | 30 | 33 | 20 | 32 | 4.93 | 40Cr | Quench HRC36-44° | 147.6 | 820 |

| S16 | 100 | 30 | 27 | 15 | 16 | 8 | 14 | 0.3 | 40Cr | Quench HRC36-44° | 16 | 88 |

| S20 | 125 | 34 | 33 | 17 | 18 | 8 | 17 | 0.37 | 40Cr | Quench HRC36-44° | 19.4 | 108 |

| S25 | 160 | 48 | 39 | 23 | 25 | 13 | 20 | 1.28 | 40Cr | Quench HRC36-44° | 55.8 | 310 |

| S30 | 142 | 46 | 49 | 22 | 23.5 | 14 | 25 | 1.3 | 40Cr | Quench HRC36-44° | 91.8 | 510 |

| Z16 | 100 | 40 | 35 | 18 | 20 | 12 | 17 | 0.4 | 40Cr | Quench HRC36-44° | 32.4 | 180 |

| Z20 | 125 | 50 | 46 | 24 | 26 | 15 | 20 | 0.67 | 40Cr | Quench HRC36-44° | 59.4 | 330 |

| Z20D | 125 | 52 | 60 | 24 | 26 | 16 | 26 | 1.15 | 40Cr | Quench HRC36-44° | 82.8 | 460 |

| Z25 | 160 | 58 | 55 | 28 | 30 | 18 | 25 | 2.25 | 40Cr | Quench HRC36-44° | 82.8 | 460 |

| Z25D | 160 | 66 | 64 | 29 | 31 | 22 | 28 | 2.6 | 40Cr | Quench HRC36-44° | 120.6 | 670 |

| Z30 | 142 | 64 | 50 | 29 | 30.5 | 18 | 25 | 1.8 | 40Cr | Quench HRC36-44° | 111.6 | 620 |

Products & Testing Equipments

Products Application

Packing & Delivery

Why Choose Us?

1. We are engaged in chain industry over 15 years with rich market experience. We keep improving production techniques. All the products have longer working life and have passed the market test.

2. We can design the correct chains with high quality material, good abrasion resistance, good corrosion, high strengthen and etc as per your request or the chain application.

3. We are the chain manufacturer; you can directly purchase the product from us with low price and high quality.

4. We have a professional team for international trade, they have abundant experiences and are always ready to solve problems for customers. So you have nothing to worry about.

5. We have the long-term cooperative forwarder who can give us the lowest freight. And it can help you to save the freight. What’s more, for the FCL, we will design the packages as per the container sizes with the largest capacity to save the shipping cost for both of us.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Mining Equipment, Agricultural Machinery, Coating, Spraying, Mining, Slaughtering, Assembly |

| Surface Treatment: | Polishing |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the benefits of using plastic industrial chains?

Plastic industrial chains offer several advantages in various applications. Here are some benefits of using plastic industrial chains:

- Corrosion resistance: Plastic chains are highly resistant to corrosion, making them suitable for use in corrosive environments where metal chains may degrade over time.

- Chemical resistance: Plastic chains can withstand exposure to a wide range of chemicals without deteriorating, making them ideal for applications in chemical processing or handling.

- Lightweight: Plastic chains are significantly lighter than their metal counterparts, reducing the overall weight of the system and allowing for easier handling and installation.

- Low noise: Plastic chains produce less noise during operation compared to metal chains, making them suitable for applications where noise reduction is important, such as in food processing or packaging.

- Self-lubricating: Some plastic chains are designed with self-lubricating properties, reducing the need for frequent lubrication and maintenance.

- High strength: Despite their lightweight nature, plastic chains can still provide high tensile strength and load-bearing capabilities, making them suitable for various heavy-duty applications.

- Low friction: Plastic chains exhibit low friction characteristics, resulting in smoother and more efficient operation, reducing power consumption and wear.

- Design flexibility: Plastic chains can be molded into various shapes and sizes, allowing for customization and adaptation to specific application requirements.

- Cost-effective: Plastic chains are often more cost-effective compared to metal chains, making them an economical choice for many industrial applications.

Plastic industrial chains offer a range of benefits, including resistance to corrosion, chemicals, and noise, lightweight design, self-lubrication, and design flexibility, making them suitable for a wide range of industries and applications.

Can an industrial chain be used for vertical lifting applications?

Yes, industrial chains can be used for vertical lifting applications. However, several factors need to be considered to ensure safe and efficient lifting operations:

- Chain type and strength: The industrial chain selected for vertical lifting applications must have the appropriate strength and load capacity to safely lift the intended load.

- Safety factors: It is crucial to consider the safety factors and ensure that the selected chain is capable of handling the maximum expected load without exceeding its rated capacity.

- Overhead clearance: Sufficient overhead clearance is necessary to accommodate the length of the chain and prevent any obstructions during the lifting process.

- Proper tensioning: The chain must be properly tensioned to prevent slippage or excessive slack, which can compromise the lifting operation.

- Guidance and control: Proper guidance and control mechanisms should be in place to ensure smooth and controlled vertical movement of the load.

- Maintenance and inspection: Regular maintenance and inspection of the chain are essential to identify any signs of wear, damage, or fatigue that may compromise its integrity and lifting capability.

It is important to consult industry standards, regulations, and specific manufacturer guidelines to determine the suitability of an industrial chain for a vertical lifting application. Additionally, working with experienced professionals and following established safety protocols is crucial to ensure the safe and effective use of the industrial chain in lifting operations.

What are the maintenance requirements for an industrial chain?

Maintaining an industrial chain is crucial to ensure its optimal performance and extend its lifespan. Here are some key maintenance requirements for industrial chains:

- Cleaning: Regularly clean the industrial chain to remove dirt, debris, and contaminants that can cause friction and wear. Use a suitable solvent or cleaning agent recommended by the chain manufacturer.

- Lubrication: Apply the appropriate lubricant to the chain according to the manufacturer’s recommendations. Lubrication reduces friction, minimizes wear, and helps prevent corrosion. Regularly inspect the lubrication levels and replenish as needed.

- Tension Adjustment: Check the tension of the industrial chain regularly. Ensure it is within the recommended range specified by the manufacturer. Improper tension can lead to excessive wear, reduced performance, and increased stress on the chain components.

- Alignment: Verify that the industrial chain is properly aligned with the sprockets or pulleys. Misalignment can cause uneven wear and premature failure. Adjust the alignment as necessary.

- Inspection: Periodically inspect the industrial chain for signs of wear, corrosion, damaged links, or other abnormalities. Look for elongation, bent or broken links, and excessive wear on the sprockets. Replace any worn or damaged components promptly.

- Environment: Consider the environmental conditions in which the industrial chain operates. Protect the chain from excessive moisture, extreme temperatures, and corrosive substances. Implement appropriate measures such as covers, guards, or coatings to safeguard the chain.

- Documentation: Keep records of maintenance activities, including lubrication schedules, tension adjustments, inspections, and any repairs or replacements. This documentation helps track the chain’s history and aids in future maintenance planning.

Following these maintenance requirements will help ensure the reliability, efficiency, and longevity of the industrial chain. It is important to refer to the manufacturer’s guidelines and recommendations for specific maintenance procedures and intervals for your particular chain type and application.

editor by CX 2023-10-07

China supplier Drive Roller Conveyor Leaf Hollow Pin Industrial Chain Elevator Silent Hoisting Pintle Cast Stainless Steel Duplex Engineering Drag Link Agricultural Escalator

Product Description

Drive Roller Conveyor Leaf Hollow Pin Industrial Chain Elevator Silent Hoisting Pintle Cast Stainless Steel Duplex Engineering Drag Link Agricultural Escalator

Product Description

Click on the picture to get the latest quotation

| transmission chain (Driving Chain) | Short Pitch Precision Roller Chain (A Series)(1,2,3) | 04C-1 06C-1-2-3 085-1-2-3 08A-1-2-3 10A-1-2-3 12A-1-2-3 16A-1-2-3 20A-1-2-3 24A-1-2-3 28A-1-2-3 32A-1-2-3 40A-1-2-3 48A-1-2-3 |

| 25 35 35-2 35-3 -2 40-3 50 50-2-50-3 60 60-2 60-3 80 80-2 80-3 100 100-2 100-3 120 120-2 120-3 140 140-2 160 160-2 -2 240 | ||

| Short Pitch Precision Roller Chain (B Series)(1,2,3) | 06B-1-2-3 06B-1-2-3 08B-1-2-3 10B-1-2-3 12B-1-2-3 16B-1-2-3 20B-1-2-3 24B-1-2-3 28B-1-2-3 32B-1-2-3 40B-1-2-3 48B-1-2-3 56B-1-2-3 64B-1-2-3 72B-1-2-3 | |

| Heavy Duty Series Roller Chain(1,2) | 08AH-1 10AH-1 12AH-1-2-3 16AH-1-2-3 20AH-1-2-3 24AH-1-2-3 28AH-1-2-3 32AH-1-2-3 40AH-1-2-3 | |

| Side Bow Chain | 40SB 43SB 50SB 60SB 63SB 80SB 08BSB 08BSBY1 10BSB 12BSB C2050SB | |

| Motorcycle Chain | 410 415 415H 420 420H 428 428H 520 520H 525 525H 530 530H 630 630H | |

| Engine Mechanism Chain (Timing Chain) | CL04 | |

| Self-Lubrication Roller Chain | 08BSLR 10BSLR 12BSLR 16BSLR 40SLR 50SLR 60SLR 80SLR | |

| Double Pitch Transmission Chain | 208A 208B 210A 210B 212A 212B 216A 216B 220A 220B | |

| 2040 2050 2060 2080 2100 | ||

| Bush Chain | P15F-B P20-B P25-B P25F1-B P30F2-B P36-B P40-B P45-B P50-B P55-B P60-B P70-B P80-B | |

| Conveyor Chain | Roller Chains With Straight Side Plates (A Series) | C08A-1-2-3 C10A-1-2-3 C12-1-2-3 C24A-1-2-3 C32A-1-2-3 |

| C35 C40-1-2-3 C50-1-2-3 C80-1-2-3 C100-1-2-3 C120-1-2-3 C140-1-2-3 C160-1-2-3 | ||

| Roller Chains With Straight Side Plates (B Series) | C08B-1-2-3 C10B-1-2-3 C12B-1-2-3 C16-1-2-3 C20B-1-2-3 C24B-1-2-3 C28B-1-2-3 C32B-1-2-3 | |

| Double Pitch Conveyor Chain | C208A C208AH C208B C208BL C210A C210AL C212A C212AH C212AHL C216A C216AL C216AH C216AHL C220A C220AL C220AH C220AHL C224A C224AL C224AH C224AHL C232A C232AL C232AH C232AHL | |

| C2050 C2052 C2060 C2062 C2060H C2080 C2080H C2082 C2082H C2100 C2100H C2102 C2102H C2120 C2120H C2122 C2122H C2160 C2160H C2162 C2162H | ||

| Double Pius Speed Chain | BS25-C206B BS25-C208A BS25-C210A BS25-C212A BS30-C206B BS30-C208B BS30-C210B BS30-C212B | |

| Conveyor Chain (M Series) | M20 M28 M40 M56 M80 | |

| Hollow Pin Conveyor Chain (MC Series) | MC28 MC56 MC112 MC224 | |

| Conveyor Chain (FV Series) | FV40 FV63 FV90 FV112 FV140 | |

| Conveyor Chain (FVT Series) | FVT40 FVT63 FVT90 FVT112 FVT140 FVT180 FVT250 FVT315 | |

| Hollow Pin Conveyor Chain (FVC Series) | FVC63 FVC90 FVC112 FVC140 FVC180 FVC250 FVC315 | |

| Conveyor Chain (Z Series) | Z40 Z100 Z160 Z300 | |

| Conveyor Chain (ZE Series) | ZE40 ZE100 ZE160 ZE300 | |

| Hollow Pin Conveyor Chain (ZC Series) | ZC21 ZC40 ZC60 ZC150 ZC300 | |

| Hollow Pin Chains | 08BHPF 08BHPF5 08BHP9 10BHPF3 10BHPF4 12BHPF2 12BHPF3 16BHPF3 16BHPF4 40HP 08BHPF7 08BHP 50HP 50HPF4 50H-HP 60HP 60HPF1 80HP 80HPF1 80HPF2 80H-HP 80HPF3 80HPF4 HB41.75F5 A2080HP | |

| Welded-type cranked link chains | WR78 WH78 WR82 WH82 WR106 WH106 WR110 WH110 WR111 WH111 WR124 WH124 WR132 WH132 WR150 WH150 WR155 WH155 WR157 WH157 WR78F5 WH78F4 WH124F1 WH111F1 | |

| Palm oil Chains | P101.6F2 P152F14 P152F17 P152F29 90R-S P101.6F64 P76.7 P152F31 | |

| Sugar mill chains | DH9063 DH2198 P152F93K2 P152F78K2 DH 0571 0 DH1796 P152F77-AS2 P203.2F9 | |

| Rubber gloves carrier chains | P100F155 P100F13 P100F139 P150/90 | |

| Lumber conveyor chains | 81X 81XH 81XHE 81XHH 81XHS 500R 441.100R | |

| Sharp top chains | 08AF34 08BF21 10AF8 41F6 06BF1 06BF37 08AF41 08BF44 08AF8… | |

| Stainless Steel Chain | Stainless Steel Short Pitch Precision Roller Chain(A Series) | 25SS-1 35SS-1 41SS-1 40SS-1 50SS-1 60SS-1 80SS-1 100SS-1 120SS-1 |

| Stainless Steel Short Pitch Precision Roller Chain(B Series) | 05BSS-1 06BSS-1 08BSS-1 10BSS-1 12BSS-1 16BSS-1 20BSS-1 24BSS-1 | |

| Stainless Steel Roller Chain With Straight Side Plates | C40SS-1 C50SS-1 C60SS-1 C80SS-1 C100SS-1 C120SS-1 C08BSS-1 C10BSS-1 C12BSS-1 C16BSS-1 C20BSS-1 C24BSS-1 | |

| Stainless Steel Double Pitch Transmission Chain | 2040SS 2050SS 2060SS 2080SS 2100SS 2120SS 208BSS 210BSS 212BSS 216BSS 220BSS 224BSS | |

| Stainless Steel Double Pitch Conveyor Chain | C2040SS C2040HSS C208BSS C2050SS C2060SS C2060HSS C2080SS C2080HSS C2100SS C2100HSS C2120SS C2120HSS | |

| Stainless Steel Hollow Pin Chain | 08BHFSS 40HPSS 50HPSS 60HPSS 12BHPSS 80HPSS C2040HPSS C2050HPSS C2060HPSS C2080HPSS HB50.8SS | |

| Stainless Steel Double Pitch Hollow Pin Chain | C2042HPSS C2052HPSS C2062HPSS C2082HPSS C2042H-HPSS C2052H-HPSS C2062H-HPSS C2082H-HPSS | |

| Lifting Chain | Car Parking Chain | 12AT-1 16AT-1-2 20AT-1-2-3 24AT-1-2 |

| Leaf Chain | LH0822 LH0823 LH571 LH0844 LH0846 LH 0571 LH1571 LH1571 LH1034 LH1044 LH1046 LH1066 LH1088 LH1222 LH1223 LH1234 LH1244 LH1246 LH1266 LH1288 | |

| BL422 BL423 BL434 BL444 BL446 BL466 BL488 BL522 BL523 BL534 BL544 BL546 BL566 BL588 BL622 BL623 BL634 BL644 BL646 BL666 BL688 | ||

| Multiple Plate Bearing Pin Chain | LF30 MP50F2 MP50.8 MP70F1 MP70F2 MP70F3 MP80F1 MP90F1 MP90F2 MP110F1 | |

| Rollerless Lift Chain | 45-1 55-1 65-1 85-1 105-1 125-1 145-1 165-1 | |

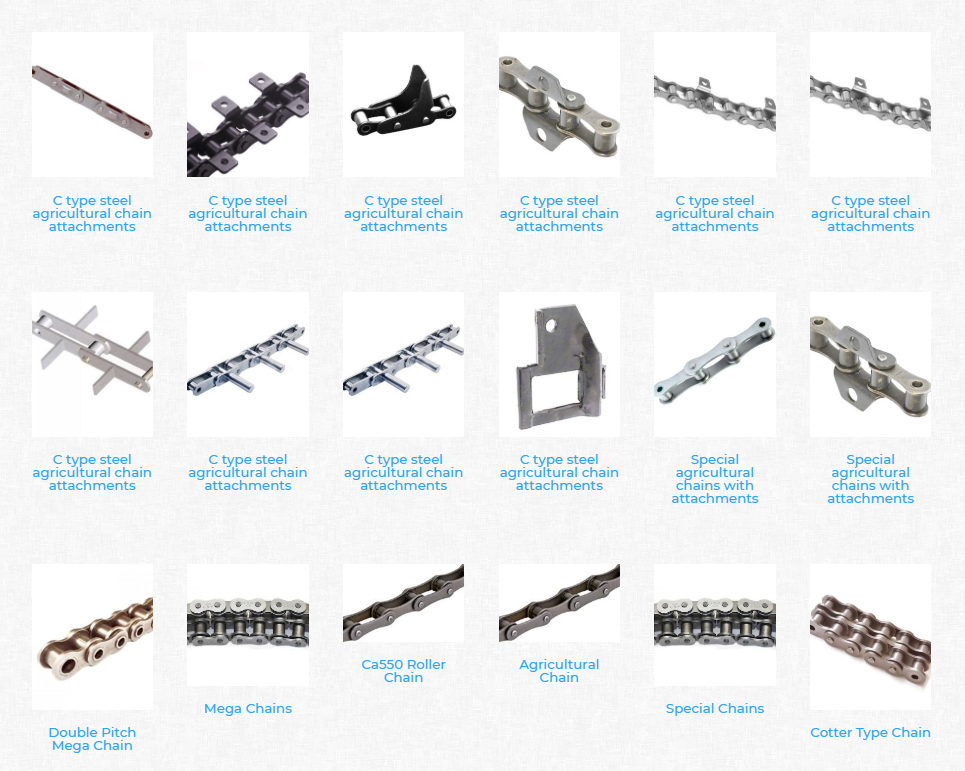

| Agricultural Chain | S Type Steel Agricultural Chain & Attachments | S32 S42 S45 S52 S55 S62 S77 S88 A550 A620 |

| C Type Steel Agricultural Chain with Attachments | CA550 CA550/S55 CA555 CA550HD CA550V CA557 CA620 CA2801 38.1R 38.4R 38.4V 38.4VB | |

| Rice Harvester Chain | S3558T-48001 S3558T-48002 | |

| Drop Forged Chain Series | Drop Forged Rivetless Chain | Imperial: 80H X348 X458 468H X658 X678 678 698 998 9118 S348 S458 S678 S698 S9118, Metric system: XT100 XT160 |

| Cast Detachable Chain | 55 57 62 74 78 | |

| Steel Detachable Chain | 25 32 32W 51 52 55 62 | |

| Cast Iron Chain | Cast Iron Chain (C Series) | C55 C55L C77 C188 C188L C102B C111 C131 C132 |

| Cast Iron Chain (H Series) | H60 H78 H82 H110 | |

| Cast Iron Chain (4 Series) | 462 477 488 4103 720 720S 730 | |

| Cast Iron Chain BRH188 | BRH188 C188CP C102B-K2 C55A C55B C55D CC600 H78A H78B H130 H138 MC33 103 4103F29 907-E51 | |

| Welded chains | WR78 WH78 WR82 WH82 WR124 WH124 | |

| Forging Hanging Chain | X228 X348 X458 X678 698 |

Our Advantages

1. The material shall be 40Cr or above alloy steel

2. All raw materials are customized by large domestic steel plants. Before entering the plant, secondary tests are carried out to ensure stable and controllable product materials.

3. The basic amount of chain parts have realized white motion and CNC-controlled production

4. Mesh belt furnaces, infiltration, high frequency, etc., are used for heat treatment to make the chain plate and shaft sleeve reach the working state. The quenching medium is made of Korean Dragon base oil

5. Professional inspection personnel are assigned to inspect each level to ensure the product quality

6. Over 20 years of operation, we have accumulated a lot of practical experience, especially in the non-standard chain leading city, which enjoys a good reputation in the industry

Related products

Company Profile

The company mainly produces a variety of A and B series of short pitch precision roller chains for transmission, double pitch transmission chains, double pitch conveying roller accessories, short pitch conveying roller chain accessories, stereo garage chains, pin chains, double speed chains, scraper chain, pumping unit chain, sugar machinery particular chain, hollow pin roller chain and sleeve chain, large roller conveying chain and accessories, ZGS38 combine chain and accessories, S-type C-type steel agricultural machinery chain and accessories, conveyor chain, beer and beverage machinery conveyor chain, side bend flat top conveyor chain, brown oil press conveyor chain, etc. – series.

Our company has Ward, Yangli, and other precision stamping equipment. CZPT laser cutting machine, automatic submerged arc welding machine, and other cutting equipment. XH precision leveling equipment, DM high-speed circular saw machine, CNC lathe, heavy double-end square milling machine, and other machining equipment. Fully automatic mesh belt quenching line, well-type gas carburizing furnace, vacuum mold furnace, high-frequency furnace, and other heat treatment equipment, lifting and hanging shot blasting machine barrel, and other surface treatment equipment.

Our company has a CZPT technical force, advanced technology, a short development cycle of new products, and complete and perfect testing. The products are sold all over the world.

| Usage: | Transmission Chain, Drag Chain, Conveyor Chain, Dedicated Special Chain |

|---|---|

| Material: | Iron |

| Surface Treatment: | Oil Blooming |

| Feature: | Oil Resistant |

| Chain Size: | 1/2"*3/32" |

| Structure: | Roller Chain |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What are the design considerations for a long-span industrial chain conveyor?

Designing a long-span industrial chain conveyor requires careful consideration of several factors to ensure optimal performance and reliability. Here are some key design considerations:

- Chain selection: Choose a chain that is specifically designed for long-span conveyors. Consider factors such as chain strength, wear resistance, and fatigue resistance to handle the load and stress over the extended distance.

- Tensioning system: Implement an effective tensioning system to maintain proper tension in the chain throughout the conveyor’s length. This helps prevent chain slack and ensures smooth operation.

- Support structure: The support structure should be robust and capable of handling the weight of the conveyor and the conveyed materials over the long span. Consider factors such as the material used, structural design, and stability.

- Drive system: The drive system should be appropriately sized and positioned to ensure consistent and efficient power transmission along the entire length of the conveyor. Consider factors such as motor power, gear ratio, and drive unit placement.

- Guiding system: Implement an effective guiding system to keep the chain aligned and prevent deviation or misalignment. This helps ensure smooth and reliable operation, especially over long distances.

- Material handling: Consider the characteristics of the conveyed material, such as size, weight, and flow rate, to determine the appropriate design features such as conveyor width, chain speed, and loading/unloading mechanisms.

- Safety features: Incorporate necessary safety features such as emergency stops, guards, and interlocks to ensure operator safety and prevent accidents.

- Maintenance access: Design the conveyor with easy access points for maintenance and inspection. This allows for routine maintenance tasks, such as chain lubrication and cleaning, to be performed efficiently.

- Environmental conditions: Consider the environmental factors that may impact the conveyor’s performance, such as temperature, humidity, and exposure to contaminants. Choose materials and components that can withstand these conditions.