Product Description

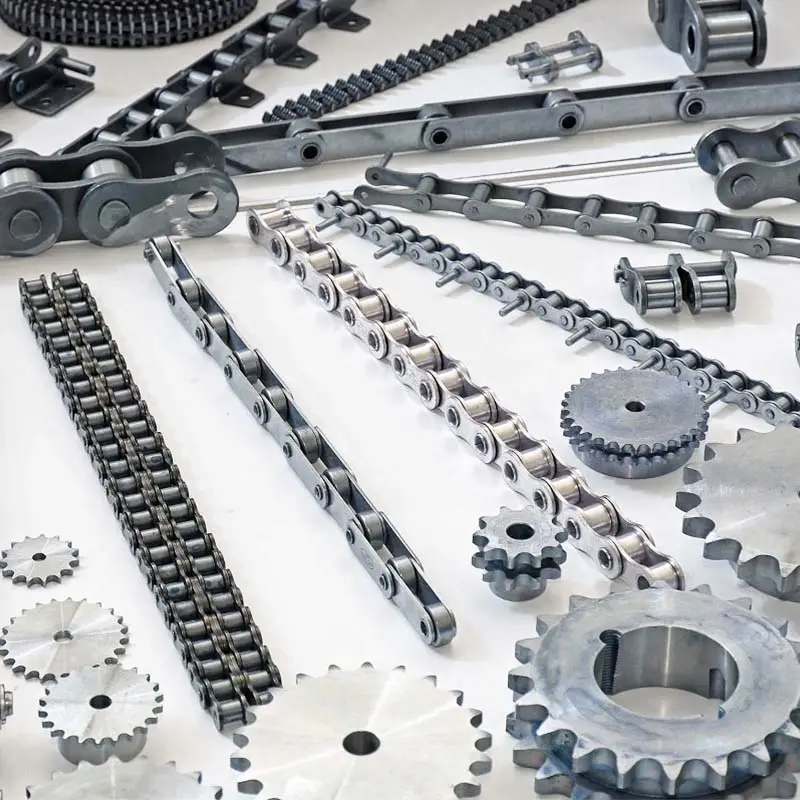

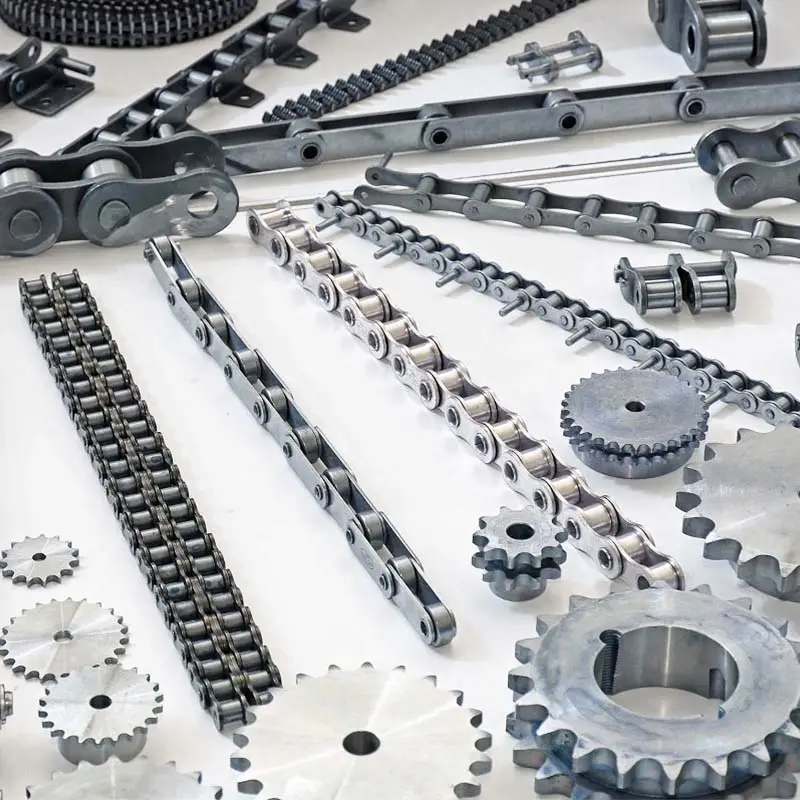

Precision industrial chain 20A-4 row chain single row double row carbon steel roller chain

Product introduction

| Material | Carbon steel, alloy steel |

| Surface Treatment | Polishing,Original Colour,Polishing |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery ……… |

| Standard or Nonstandard | Standard |

| Heat Treatment: | High Temperature Hardening |

| Color | Elf,dark yellow,dark blue,black |

| Features |

•Large reduction ratio (usually up to 1:7) |

HIGH STHangZhouRD HEAT TREATMENT

Through high standards,strictly control the heat,improve the hardness/strength and provide service life.

HIGH QUALITY MATERIAL

Beautiful and corrosion-resistant, the product surface is treated with rust prevention, beautiful and simple!

STHangZhouRD THICKNESS CHAIN PIECE

The thickness is customized from raw material chain plate in strict accordance with the standard

STHangZhouRD CHINAMFG PIN

Cutting in strict accordance with the standard, second screening,

and never cut corners

Green Power Industry Co Llimited is an international export enterprise combined with factory specializing in the manufacturing of brake system , clutch system,spark plug and chain . Our company is a professional manufacturer and supplier of brake,chain and clutch in China. We both have our own brake CHINAMFG factory, brake pad factory, brake shoe factory ,clutch disc factory,chain factory, spark plug factory .We focus on developing high-quality products for OEM market ,Our company have developed and produced high quality brake in formula non -metallic and asbestos free for automobile and brake shoe assembly for heavy duty truck . The production are noted good characteristics such as high strength , high heat-resisting , wear-resisting.low dust virtue ,no noise and better stability . The series products had been exporting to North -America ,Europe ,Middle -East ,Australia and etc, widely sale to domestic OEM factories and aftermarket.

Our company is composed of professional team , process advanced production inspection and testing equipment Each product have passed the first inspection, process inspection, error prevention, and laboratory tests to ensure that each piece of qualified products sent to customers

We are determined to set up the aim of “excellent quality and satisfying service·, with·the first class quality , reasonable price and perfect service . we set strick demand and operate conforming to the standard to guarantee all the products can be meet our customer’s needs

1.Q: What is the certificate of your factory?

A: We have passed IAF ISO and TS16949 certification.

2.Q: Can it be produced according to the sample?

A: Yes, we can produce through your samples or technical drawings. We can build molds and fixtures.

3.Q: Do you test all products before shipping?

A: Yes, we conduct 100% quality testing before delivery, and we are 100% responsible for product quality.

4.Q: What is your delivery time?

A:If we have stock, we can send it immediately within a week. If not, it usually ranges from 7 days to 35 days, depending on the quantity.

5.Q: What is your sample policy?

A: We want to provide you with samples for approval. There will be no charge for 1 or 2 samples, but the customer needs to bear the courier fee first.

It will be drawback to customer when order placed

6.Q: How do you make our business establish a long-term good cooperative relationship?

A:1. We maintain excellent quality and competitive prices to ensure that our customers benefit;

2. We respect every customer as our friend, we do business sincerely and make friends widely,No matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain, Conveyor Chain |

|---|---|

| Material: | Carbon steel, alloy steel |

| Surface Treatment: | Polishing |

| Feature: | Heat Resistant |

| Chain Size: | 1/2"*3/32" |

| Structure: | Roller Chain |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you troubleshoot chain skipping or slipping issues in an industrial chain?

Chain skipping or slipping issues in an industrial chain can lead to decreased efficiency and potential equipment damage. Here are some steps to troubleshoot and address these issues:

- Check chain tension: Ensure that the chain is properly tensioned according to the manufacturer’s recommendations. An overly loose or tight chain can cause skipping or slipping.

- Inspect sprockets: Examine the sprockets for signs of wear, damage, or misalignment. Worn or damaged sprocket teeth can cause chain skipping. Correct any alignment issues and replace worn sprockets if necessary.

- Inspect chain condition: Inspect the chain for signs of wear, elongation, or damage. A worn or stretched chain may not properly engage with the sprockets, leading to skipping or slipping. If the chain is significantly worn, it may need to be replaced.

- Clean and lubricate the chain: Clean the chain thoroughly to remove any debris or contaminants that may be affecting its performance. Apply a suitable lubricant to ensure smooth operation and reduce friction.

- Check drive system components: Examine other components of the drive system, such as bearings, shafts, and gears, for any signs of damage or misalignment. These components can also contribute to chain skipping or slipping.

- Adjust alignment: Ensure that the entire chain drive system is properly aligned. Misalignment can cause uneven tension distribution and lead to chain skipping. Adjust the alignment as needed.

- Inspect drive system tensioners: If the chain drive system includes tensioners, check their condition and adjustment. A malfunctioning or improperly adjusted tensioner can contribute to chain skipping.

- Consult manufacturer guidelines: Refer to the manufacturer’s guidelines and specifications for the specific industrial chain and equipment being used. Follow their recommended troubleshooting steps and maintenance practices.

- Seek professional assistance if needed: If the issue persists or if you are unsure about the troubleshooting process, it is recommended to seek assistance from a qualified technician or the manufacturer’s technical support team.

Addressing chain skipping or slipping issues promptly is important to prevent further damage and maintain the efficiency and reliability of the industrial chain system.

How do you optimize the efficiency of an industrial chain system?

Optimizing the efficiency of an industrial chain system involves various factors and considerations. Here are some key steps to achieve maximum efficiency:

1. Proper Design: Ensure that the industrial chain system is designed correctly for the specific application. Consider factors such as load capacity, speed, environment, and required service life when selecting the chain and related components.

2. Adequate Lubrication: Proper lubrication is essential for reducing friction, wear, and energy loss in the chain system. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant type and quantity.

3. Correct Tensioning: Maintaining the right tension in the chain is crucial for optimal performance. Over-tensioning or under-tensioning can lead to increased wear, power loss, and premature failure. Regularly check and adjust the tension as per the manufacturer’s guidelines.

4. Alignment and Sprocket Inspection: Ensure proper alignment of the chain and sprockets. Misalignment can cause excessive wear and energy loss. Regularly inspect the sprockets for signs of wear, damage, or misalignment, and replace or adjust as necessary.

5. Minimize Friction and Resistance: Reduce friction and resistance throughout the chain system by keeping the components clean and free from debris. Regularly clean and inspect the chain, sprockets, and guides to remove any accumulated dirt or contaminants.

6. Maintenance and Inspection: Implement a regular maintenance and inspection schedule for the entire chain system. This includes checking for wear, lubrication status, tension, and alignment. Address any issues promptly to prevent further damage and ensure optimal performance.

7. Training and Education: Provide proper training to operators and maintenance personnel on the correct handling, operation, and maintenance of the industrial chain system. This will help ensure that everyone understands the importance of efficiency and follows best practices.

By following these optimization strategies, the efficiency of an industrial chain system can be improved, leading to reduced energy consumption, extended service life, and cost savings in the long run.

What are the signs of wear and tear in an industrial chain?

Monitoring the condition of an industrial chain is essential to identify signs of wear and tear. Here are some common signs to watch for:

- Chain Elongation: Measure the chain’s pitch to check for elongation. Excessive elongation indicates wear in the chain and can lead to poor performance and premature failure.

- Worn Sprocket Teeth: Inspect the sprocket teeth for signs of wear. Worn or misshapen teeth can cause the chain to skip or slip, resulting in decreased efficiency and increased stress on the system.

- Chain Flexibility: Assess the flexibility of the chain by bending it. If the chain is stiff or has tight spots, it may indicate corrosion, inadequate lubrication, or worn components.

- Visible Damage: Look for any visible damage on the chain, such as bent links, cracked or broken plates, or missing pins or rollers. These can weaken the chain’s integrity and compromise its performance.

- Excessive Noise: Unusual noise during operation, such as grinding, rattling, or squeaking, can indicate a problem with the chain. It may be caused by misalignment, inadequate lubrication, or worn components.

- Increased Friction: Check for excessive heat or signs of friction, such as discoloration or hot spots. Increased friction can accelerate wear and lead to premature failure.

- Poor Tension: Assess the chain’s tension by checking for slack or excessive tightness. Improper tension can cause the chain to wear unevenly and affect its performance.

Regular inspections and maintenance are crucial to identify these signs of wear and tear. Addressing issues promptly, such as replacing worn components or adjusting tension, can help prolong the life of the industrial chain and prevent unexpected failures.

editor by CX 2024-05-06

China wholesaler Industrial Drive Roller Conveyor Leaf Chain Hoisting Hollow Pin Heavy Duty Stainless Steel Short Double Pitch (AL BL LL)

Product Description

Product Description

Industrial Drive Roller Conveyor Leaf Chain

HangZhou Vision Chain Transmission Co., Ltd. offers a wide range of leaf chains that meet ISO, BS, JS, and other industry standards. Our leaf chains are made of high-quality materials and undergo advanced heat treatment technology, ensuring durability and reliability.

Our leaf chain series include BL, AL, LL, and FL, which are designed for various applications. Whether you need a leaf chain for forklift trucks, textile machinery, drilling rigs, or any other equipment requiring vertical lifting or horizontal traction, we have the right solution for you.

At HangZhou Vision Chain Transmission Co., Ltd., we understand that every customer has unique requirements. That’s why we offer customized leaf chain services to meet your specific needs. Just let us know your requirements, and our team will provide you with a tailored solution.

Key Features:

- High-quality materials and heat treatment technology

- Meets ISO, BS, JS, and other industry standards

- Available in BL, AL, LL, and FL series

- Customized leaf chain service

- Wide range of applications

Choose HangZhou Vision Chain Transmission Co., Ltd. for reliable and efficient leaf chains that deliver exceptional performance. Contact us today to discuss your leaf chain requirements.

Product Attribute

|

Usage |

Leaf Chain ,Flyer chain |

|

Material |

Alloy/Carbon Steel |

| Application industry | Metallurgy, coal, electricity, food, chemical industry, tobacco, beverage, etc |

|

Surface Treatment |

Self-color Sand-blasted Shot-peening |

| Product Series |

AL,BL ,LL,FL,LH |

| Port |

Any sea port or airport in China |

| Brand | TV OEM |

| Payment |

L/C, T/T, D/P, Western Union |

| Package |

Chain, Plastic Bag, Color Box, Wooden Case. or OEM |

| AL Series |

AL322,AL344,AL422,AL444,AL466,AL522,AL534,AL544,AL566,AL622,AL644,AL666,AL688 AL822,AL844,AL866,AL888,AL1571,AL1044,AL1066,AL1088,AL1222,AL1244,AL1266,AL1288 AL1444,AL1466,AL1644,AL1666,AL1688 |

| BL Series | BL422,BL423,BL434,BL444,BL446,BL488,BL522,BL523,BL534,BL544,BL546,BL566,BL588

BL622,BL623,BL634,BL644,BL646,BL688,BL822,BL823,BL834,BL844,BL846,BL866,BL888 BL1571,BL1571,BL1034,BL1044,BL1046,BL1088,BL1222,BL1223,BL1234,BL1244,BL1246 BL1266,BL1288,BL1422,BL1423,BL1434,BL1444,BL1446,BL1488,BL1622,BL1623,BL1634 BL1644,BL1646,BL1666,BL1888,BL2571,BL2571,BL2034,BL2044,BL2046,BL2088 |

| LL Series | LL0622,LL0644,LL0666,LL0822,LL0844,LL0866,LL 0571 ,LL1571,LL1044,LL1066,LL1088,LL1222

LL1244,LL1266,LL1288,LL1622,LL1644,LL1666,LL1688,LL2571,LL2044,LL2066,LL2088,LL2422 LL2444,LL2466,LL2488,LL2822,LL2844,LL2866,LL2888,LL3222,LL3244,LL3266,LL3288,LL4571 LL4044,LL4066,LL4088,LL4822,LL4844,LL4866,LL4888 |

| LH Series | LH0822,LH0823,LH571,LH0844,LH0846,LH0866,LH 0571 ,LH1571,LH1571,LH1034,LH1044

LH1046,LH1066,LH1088,LH1222,LH1223,LH1234,LH1244,LH1246,LH1266,LH1288,LH1622 LH1623,LH1634,LH1644,LH1646,LH1666,LH1688,LH2571,LH2571,LH2034,LH2044,LH2046 LH2066,LH2088,LH2422,LH2423,LH2434,LH2444,LH2446,LH2466,LH2488,LH2822,LH2823 LH2834,LH2844,LH2846,LH2866,LH2888,LH3222,LH3223,LH3234,LH3244,LH3246,LH3266 LH3288,LH4571,LH4571,LH4034,LH4044,LH4046,LH4066,LH4088 |

| FL Series | FL644,FL666,FL688,FL523,FL844,FL922,FL944,FL945,FL956,FL966,FL988 |

| We also carry out OEM according to your requirements |

|

Detailed Photos

Product Parameters

Our Advantages

Company Advantages:

– Own Import & Export License

– TV trademark registered successfully in multiple countries

– Sales network covering China and exporting to 65 countries CHINAMFG

Membership:

– Member of China General Machine Components Industry Association

– Member of China Chain Transmission Association

– Member of China Chain Standardization Association

– Member of China Agricultural Association Machinery Manufacturers

With our highly trained staff and workers, advanced and efficient equipment, extensive sales network, and strict quality assurance systems, you can be confident that our premium qualified chain meets the highest standards and specifications.

Contact us now for more information on how TransVision products can fulfill your industry’s demands at competitive prices.

Quality First, Clients Uppermost.

Product Description:

HangZhou Vision Chain Transmission Co., Ltd. presents the Industrial Drive Roller Conveyor Leaf Chain Hoisting Hollow Pin Heavy Duty Stainless Steel Short Double Pitch (AL BL LL). This transmission chain is designed for various applications and is made of high-quality materials. With its durable construction and excellent performance, it ensures reliable and efficient operation.

Key Features:

– Suitable for transmission chain applications

– Made of high-quality materials

– Surface treatment: Other

Don’t miss out on the opportunity to enhance your operations with our top-notch chain. Contact us now for more information and take advantage of our competitive pricing.

HangZhou Vision Chain Transmission Co., Ltd. offers a range of industrial drive roller conveyor leaf chains. These chains are heavy-duty, stainless steel, and designed for hoisting and transmission purposes. Choose from various types, including AL, BL, and LL chains. Perfect for conveyor systems and other applications.

| WHY CHOOSE US |

Product Description

Introducing our comprehensive product portfolio from HangZhou Vision Chain Transmission Co., Ltd. We are proud to offer a wide range of power transmission products to meet all your needs. Our product lineup includes drive chains, conveyor chains, agricultural chains, sprockets, and couplings. With our one-stop shopping experience, you can easily find what you’re looking for with just 1 click, saving you time and effort.

Our products are the perfect combination of quality and affordability. We understand the importance of staying within your budget, and that’s why we offer value choice products that deliver exceptional performance without breaking the bank.

When you choose us, you’ll have the support of our seasoned sales associates and engineers. Our team consists of 15 experienced sales associates and 5 knowledgeable engineers who are always ready to lend a helping hand. With their industry know-how, they can provide you with expert advice and assistance. You can count on them to respond to your requests within 24 hours.

Our commitment to customer satisfaction is evident in our 100% customer retention rate. Our regular customers from overseas keep coming back not only for our premium quality products but also for the superior services we’ve provided over the years.

Experience the difference with HangZhou Vision Chain Transmission Co., Ltd. Choose us for all your power transmission needs and enjoy the convenience, quality, and excellent service we offer. Shop now and discover why we are the preferred choice for customers worldwide.

| FAQ |

| Q1: What’s your average lead time? A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate. Q2: Is your price better than your competitors given the same quality? Q4: Can we inspect the goods before shipment? Q5: What kind of payment method is acceptable for your mill? Q6: What if I have any other questions? |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Natural |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the best practices for storing and handling industrial chains?

Storing and handling industrial chains properly is essential to maintain their performance, prevent damage, and ensure safe operation. Here are some best practices to follow:

- Proper Storage: Store industrial chains in a clean, dry, and well-ventilated area to protect them from moisture, dust, and corrosive elements. Use designated storage racks or containers to keep them organized and prevent tangling or entanglement with other objects.

- Protection from Contamination: Keep industrial chains away from chemicals, solvents, and other substances that may cause corrosion or degradation. If necessary, use protective covers or coatings to shield the chains from environmental contaminants.

- Regular Inspection: Perform regular visual inspections of the chains for signs of damage, wear, or misalignment. Check for bent or damaged links, worn-out rollers or sprockets, and any abnormal wear patterns. Address any issues promptly to prevent further damage or failure.

- Proper Handling Techniques: When handling industrial chains, use appropriate lifting equipment or tools to avoid excessive bending or twisting. Avoid dropping or impacting the chains, as it can cause deformation or damage to the links.

- Correct Installation: Follow the manufacturer’s guidelines and recommended procedures for installing industrial chains. Ensure proper alignment of sprockets, correct tensioning, and appropriate lubrication to optimize performance and prevent premature wear.

- Regular Lubrication: Apply the recommended lubricant to the industrial chains according to the manufacturer’s specifications. Proper lubrication reduces friction, wear, and noise, and helps extend the chain’s lifespan.

- Training and Safety: Provide proper training to personnel involved in handling industrial chains. Ensure they understand the safety procedures, including wearing appropriate personal protective equipment and following safe work practices.

By following these best practices for storing and handling industrial chains, you can prolong their lifespan, maintain their performance, and ensure safe and reliable operation in your industrial applications.

What are the noise levels associated with industrial chains?

The noise levels associated with industrial chains can vary depending on several factors, including chain design, lubrication, and operating conditions.

Chain Design: The design of the industrial chain, including the type of chain and its construction, can impact noise levels. Chains with smoother surfaces and precision manufacturing techniques tend to produce less noise.

Lubrication: Proper lubrication of the chain is essential for reducing noise. Applying a suitable lubricant to the chain can minimize friction and vibration, resulting in quieter operation.

Operating Conditions: The operating conditions of the industrial chain, such as the load, speed, and tension, can also affect noise levels. Higher loads and speeds, as well as inadequate tensioning, can increase noise levels.

Overall, it is important to consider noise levels when using industrial chains, particularly in noise-sensitive environments. Implementing proper chain design, regular lubrication, and maintaining appropriate operating conditions can help minimize noise and create a more comfortable work environment.

How does an industrial chain work in a manufacturing process?

An industrial chain plays a crucial role in a manufacturing process by facilitating the movement of materials or products along a predetermined path. Here’s a detailed explanation of how an industrial chain works:

- Input of materials: The manufacturing process begins with the input of raw materials or components onto the industrial chain. These materials are usually placed onto the chain manually or through automated systems.

- Chain movement: The industrial chain is set into motion, either by a motor or by connecting it to a power source. As the chain moves, it carries the materials or products along its path.

- Transfer and handling: The materials or products are transferred from one workstation to another as they move along the industrial chain. This transfer can involve various processes such as assembly, inspection, packaging, or any other manufacturing operation.

- Control and synchronization: The movement of the industrial chain is controlled and synchronized to ensure proper timing and coordination of the manufacturing process. This can be achieved through the use of sensors, actuators, and control systems that monitor and adjust the speed, direction, and position of the chain.

- Output and completion: As the materials or products reach the end of the industrial chain, they are either ready for further processing or considered as finished goods. They are then removed from the chain and directed to the next stage of the manufacturing process or prepared for shipment.

The working principle of an industrial chain involves the continuous loop movement of the chain, which allows for the smooth and controlled transfer of materials or products. The chain’s design, including the type of links, pitch, and attachments, is optimized to meet the specific requirements of the manufacturing process, such as load capacity, speed, and environmental conditions.

By utilizing an industrial chain in a manufacturing process, companies can achieve increased efficiency, improved productivity, and enhanced automation. The precise and reliable movement of materials or products provided by the industrial chain ensures a streamlined and synchronized manufacturing operation.

editor by CX 2024-04-30

China supplier Industrial Drive Roller Conveyor Leaf Chain Hoisting Hollow Pin Heavy Duty Stainless Steel Short Double Pitch (AL BL LL)

Product Description

Product Description

Industrial Drive Roller Conveyor Leaf Chain

HangZhou Vision Chain Transmission Co., Ltd. offers a wide range of leaf chains that meet ISO, BS, JS, and other industry standards. Our leaf chains are made of high-quality materials and undergo advanced heat treatment technology, ensuring durability and reliability.

Our leaf chain series include BL, AL, LL, and FL, which are designed for various applications. Whether you need a leaf chain for forklift trucks, textile machinery, drilling rigs, or any other equipment requiring vertical lifting or horizontal traction, we have the right solution for you.

At HangZhou Vision Chain Transmission Co., Ltd., we understand that every customer has unique requirements. That’s why we offer customized leaf chain services to meet your specific needs. Just let us know your requirements, and our team will provide you with a tailored solution.

Key Features:

- High-quality materials and heat treatment technology

- Meets ISO, BS, JS, and other industry standards

- Available in BL, AL, LL, and FL series

- Customized leaf chain service

- Wide range of applications

Choose HangZhou Vision Chain Transmission Co., Ltd. for reliable and efficient leaf chains that deliver exceptional performance. Contact us today to discuss your leaf chain requirements.

Product Attribute

|

Usage |

Leaf Chain ,Flyer chain |

|

Material |

Alloy/Carbon Steel |

| Application industry | Metallurgy, coal, electricity, food, chemical industry, tobacco, beverage, etc |

|

Surface Treatment |

Self-color Sand-blasted Shot-peening |

| Product Series |

AL,BL ,LL,FL,LH |

| Port |

Any sea port or airport in China |

| Brand | TV OEM |

| Payment |

L/C, T/T, D/P, Western Union |

| Package |

Chain, Plastic Bag, Color Box, Wooden Case. or OEM |

| AL Series |

AL322,AL344,AL422,AL444,AL466,AL522,AL534,AL544,AL566,AL622,AL644,AL666,AL688 AL822,AL844,AL866,AL888,AL1571,AL1044,AL1066,AL1088,AL1222,AL1244,AL1266,AL1288 AL1444,AL1466,AL1644,AL1666,AL1688 |

| BL Series | BL422,BL423,BL434,BL444,BL446,BL488,BL522,BL523,BL534,BL544,BL546,BL566,BL588

BL622,BL623,BL634,BL644,BL646,BL688,BL822,BL823,BL834,BL844,BL846,BL866,BL888 BL1571,BL1571,BL1034,BL1044,BL1046,BL1088,BL1222,BL1223,BL1234,BL1244,BL1246 BL1266,BL1288,BL1422,BL1423,BL1434,BL1444,BL1446,BL1488,BL1622,BL1623,BL1634 BL1644,BL1646,BL1666,BL1888,BL2571,BL2571,BL2034,BL2044,BL2046,BL2088 |

| LL Series | LL0622,LL0644,LL0666,LL0822,LL0844,LL0866,LL 0571 ,LL1571,LL1044,LL1066,LL1088,LL1222

LL1244,LL1266,LL1288,LL1622,LL1644,LL1666,LL1688,LL2571,LL2044,LL2066,LL2088,LL2422 LL2444,LL2466,LL2488,LL2822,LL2844,LL2866,LL2888,LL3222,LL3244,LL3266,LL3288,LL4571 LL4044,LL4066,LL4088,LL4822,LL4844,LL4866,LL4888 |

| LH Series | LH0822,LH0823,LH571,LH0844,LH0846,LH0866,LH 0571 ,LH1571,LH1571,LH1034,LH1044

LH1046,LH1066,LH1088,LH1222,LH1223,LH1234,LH1244,LH1246,LH1266,LH1288,LH1622 LH1623,LH1634,LH1644,LH1646,LH1666,LH1688,LH2571,LH2571,LH2034,LH2044,LH2046 LH2066,LH2088,LH2422,LH2423,LH2434,LH2444,LH2446,LH2466,LH2488,LH2822,LH2823 LH2834,LH2844,LH2846,LH2866,LH2888,LH3222,LH3223,LH3234,LH3244,LH3246,LH3266 LH3288,LH4571,LH4571,LH4034,LH4044,LH4046,LH4066,LH4088 |

| FL Series | FL644,FL666,FL688,FL523,FL844,FL922,FL944,FL945,FL956,FL966,FL988 |

| We also carry out OEM according to your requirements |

|

Detailed Photos

Product Parameters

Our Advantages

Company Advantages:

– Own Import & Export License

– TV trademark registered successfully in multiple countries

– Sales network covering China and exporting to 65 countries CHINAMFG

Membership:

– Member of China General Machine Components Industry Association

– Member of China Chain Transmission Association

– Member of China Chain Standardization Association

– Member of China Agricultural Association Machinery Manufacturers

With our highly trained staff and workers, advanced and efficient equipment, extensive sales network, and strict quality assurance systems, you can be confident that our premium qualified chain meets the highest standards and specifications.

Contact us now for more information on how TransVision products can fulfill your industry’s demands at competitive prices.

Quality First, Clients Uppermost.

Product Description:

HangZhou Vision Chain Transmission Co., Ltd. presents the Industrial Drive Roller Conveyor Leaf Chain Hoisting Hollow Pin Heavy Duty Stainless Steel Short Double Pitch (AL BL LL). This transmission chain is designed for various applications and is made of high-quality materials. With its durable construction and excellent performance, it ensures reliable and efficient operation.

Key Features:

– Suitable for transmission chain applications

– Made of high-quality materials

– Surface treatment: Other

Don’t miss out on the opportunity to enhance your operations with our top-notch chain. Contact us now for more information and take advantage of our competitive pricing.

HangZhou Vision Chain Transmission Co., Ltd. offers a range of industrial drive roller conveyor leaf chains. These chains are heavy-duty, stainless steel, and designed for hoisting and transmission purposes. Choose from various types, including AL, BL, and LL chains. Perfect for conveyor systems and other applications.

| WHY CHOOSE US |

Product Description

Introducing our comprehensive product portfolio from HangZhou Vision Chain Transmission Co., Ltd. We are proud to offer a wide range of power transmission products to meet all your needs. Our product lineup includes drive chains, conveyor chains, agricultural chains, sprockets, and couplings. With our one-stop shopping experience, you can easily find what you’re looking for with just 1 click, saving you time and effort.

Our products are the perfect combination of quality and affordability. We understand the importance of staying within your budget, and that’s why we offer value choice products that deliver exceptional performance without breaking the bank.

When you choose us, you’ll have the support of our seasoned sales associates and engineers. Our team consists of 15 experienced sales associates and 5 knowledgeable engineers who are always ready to lend a helping hand. With their industry know-how, they can provide you with expert advice and assistance. You can count on them to respond to your requests within 24 hours.

Our commitment to customer satisfaction is evident in our 100% customer retention rate. Our regular customers from overseas keep coming back not only for our premium quality products but also for the superior services we’ve provided over the years.

Experience the difference with HangZhou Vision Chain Transmission Co., Ltd. Choose us for all your power transmission needs and enjoy the convenience, quality, and excellent service we offer. Shop now and discover why we are the preferred choice for customers worldwide.

| FAQ |

| Q1: What’s your average lead time? A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate. Q2: Is your price better than your competitors given the same quality? Q4: Can we inspect the goods before shipment? Q5: What kind of payment method is acceptable for your mill? Q6: What if I have any other questions? |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Natural |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can an industrial chain be used in corrosive or abrasive environments?

Yes, industrial chains can be used in corrosive or abrasive environments, but the selection of the appropriate chain material and proper maintenance practices are crucial for their reliable performance. Here are some considerations:

- Corrosive Environments: In corrosive environments where the chain is exposed to chemicals, moisture, or other corrosive substances, it is essential to choose a chain material that offers excellent corrosion resistance. Stainless steel chains or chains with corrosion-resistant coatings are commonly used in such applications. These materials provide protection against rust and corrosion.

- Abrasive Environments: In abrasive environments where the chain is subjected to wear and abrasion, it is important to select a chain with high hardness and resistance to wear. Chains made from materials like alloy steel or with hardened components are suitable for such conditions. Additionally, chains with specialized surface treatments or coatings can provide extra protection against abrasion.

- Maintenance Practices: Proper maintenance is essential to extend the lifespan of an industrial chain in corrosive or abrasive environments. Regular cleaning of the chain to remove contaminants and applying appropriate lubrication can help reduce friction, wear, and corrosion. Inspecting the chain regularly for signs of damage or wear and addressing any issues promptly can also prevent premature failure.

- Considerations for Material Selection: When choosing an industrial chain for corrosive or abrasive environments, consider factors such as the specific chemicals or substances present, temperature variations, humidity levels, and the intensity of abrasion. Consulting with chain manufacturers or industry experts can help in selecting the most suitable chain material and design for your specific application.

By selecting the right chain material, implementing proper maintenance practices, and considering the specific requirements of the corrosive or abrasive environment, industrial chains can effectively operate and withstand the challenges posed by such conditions.

How does an industrial chain compare to other types of power transmission systems?

An industrial chain is a type of power transmission system that offers several advantages compared to other systems:

- Strength and durability: Industrial chains are designed to handle heavy loads and withstand tough operating conditions. They are known for their high strength and durability, making them suitable for demanding industrial applications.

- Efficiency: Industrial chains provide efficient power transmission, minimizing energy loss during operation. They offer high mechanical efficiency, which is especially important in applications that require precise and consistent power transfer.

- Flexibility: Industrial chains are flexible in terms of design and configuration. They can be easily adapted to various applications and can transmit power over long distances, making them suitable for a wide range of industrial machinery and equipment.

- Cost-effectiveness: Industrial chains are often cost-effective compared to alternative power transmission systems. They are relatively simple in design, easy to manufacture, and have a lower initial cost. Additionally, their durability and longevity reduce the need for frequent replacements, resulting in long-term cost savings.

- Reliability: Industrial chains are known for their reliability and consistent performance. When properly maintained and operated within their load and speed limits, they can provide reliable power transmission for extended periods.

- Versatility: Industrial chains can accommodate various environmental conditions, including high temperatures, corrosive environments, and high-speed applications. They can be made from different materials and configured with specific features to suit specific application requirements.

While industrial chains offer numerous advantages, it is essential to consider specific application needs and requirements when selecting a power transmission system. Factors such as load capacity, operating environment, speed, and precision may influence the suitability of an industrial chain compared to alternatives such as belts, gears, or shafts.

What lubrication is recommended for industrial chains?

Choosing the right lubrication for industrial chains is essential to ensure their smooth operation and longevity. Here are some commonly recommended lubricants for industrial chains:

- Chain Oil: Chain oils are specifically formulated for industrial chain applications. They have excellent penetration and adhesion properties, providing lubrication to the chain’s internal components. Chain oils often have anti-wear and anti-corrosion additives to protect against friction and moisture.

- Grease: Greases designed for industrial chain lubrication offer good adhesion and cling properties. They provide a protective film that stays in place even under high loads and temperatures. Greases can provide long-lasting lubrication and are suitable for applications where oil may not be suitable or accessible.

- Dry Film Lubricants: Dry film lubricants, such as PTFE (polytetrafluoroethylene) or molybdenum disulfide-based coatings, are applied as a thin film to the chain. They create a low-friction barrier between the chain components, reducing wear and enhancing performance. Dry film lubricants are particularly useful in applications where oil or grease may attract dirt, dust, or contaminants.

When selecting a lubricant for industrial chains, consider factors such as operating conditions, temperature, load, speed, and environmental conditions. It’s important to consult the chain manufacturer’s recommendations and follow their guidelines for lubrication intervals and application methods. Regular lubrication and maintenance will help reduce friction, wear, and the risk of chain failures in industrial applications.

editor by CX 2024-04-23

China OEM Industrial Drive Roller Conveyor Leaf Chain Hoisting Hollow Pin Heavy Duty Stainless Steel Short Double Pitch (AL BL LL)

Product Description

Product Description

Industrial Drive Roller Conveyor Leaf Chain

HangZhou Vision Chain Transmission Co., Ltd. offers a wide range of leaf chains that meet ISO, BS, JS, and other industry standards. Our leaf chains are made of high-quality materials and undergo advanced heat treatment technology, ensuring durability and reliability.

Our leaf chain series include BL, AL, LL, and FL, which are designed for various applications. Whether you need a leaf chain for forklift trucks, textile machinery, drilling rigs, or any other equipment requiring vertical lifting or horizontal traction, we have the right solution for you.

At HangZhou Vision Chain Transmission Co., Ltd., we understand that every customer has unique requirements. That’s why we offer customized leaf chain services to meet your specific needs. Just let us know your requirements, and our team will provide you with a tailored solution.

Key Features:

- High-quality materials and heat treatment technology

- Meets ISO, BS, JS, and other industry standards

- Available in BL, AL, LL, and FL series

- Customized leaf chain service

- Wide range of applications

Choose HangZhou Vision Chain Transmission Co., Ltd. for reliable and efficient leaf chains that deliver exceptional performance. Contact us today to discuss your leaf chain requirements.

Product Attribute

|

Usage |

Leaf Chain ,Flyer chain |

|

Material |

Alloy/Carbon Steel |

| Application industry | Metallurgy, coal, electricity, food, chemical industry, tobacco, beverage, etc |

|

Surface Treatment |

Self-color Sand-blasted Shot-peening |

| Product Series |

AL,BL ,LL,FL,LH |

| Port |

Any sea port or airport in China |

| Brand | TV OEM |

| Payment |

L/C, T/T, D/P, Western Union |

| Package |

Chain, Plastic Bag, Color Box, Wooden Case. or OEM |

| AL Series |

AL322,AL344,AL422,AL444,AL466,AL522,AL534,AL544,AL566,AL622,AL644,AL666,AL688 AL822,AL844,AL866,AL888,AL1571,AL1044,AL1066,AL1088,AL1222,AL1244,AL1266,AL1288 AL1444,AL1466,AL1644,AL1666,AL1688 |

| BL Series | BL422,BL423,BL434,BL444,BL446,BL488,BL522,BL523,BL534,BL544,BL546,BL566,BL588

BL622,BL623,BL634,BL644,BL646,BL688,BL822,BL823,BL834,BL844,BL846,BL866,BL888 BL1571,BL1571,BL1034,BL1044,BL1046,BL1088,BL1222,BL1223,BL1234,BL1244,BL1246 BL1266,BL1288,BL1422,BL1423,BL1434,BL1444,BL1446,BL1488,BL1622,BL1623,BL1634 BL1644,BL1646,BL1666,BL1888,BL2571,BL2571,BL2034,BL2044,BL2046,BL2088 |

| LL Series | LL0622,LL0644,LL0666,LL0822,LL0844,LL0866,LL 0571 ,LL1571,LL1044,LL1066,LL1088,LL1222

LL1244,LL1266,LL1288,LL1622,LL1644,LL1666,LL1688,LL2571,LL2044,LL2066,LL2088,LL2422 LL2444,LL2466,LL2488,LL2822,LL2844,LL2866,LL2888,LL3222,LL3244,LL3266,LL3288,LL4571 LL4044,LL4066,LL4088,LL4822,LL4844,LL4866,LL4888 |

| LH Series | LH0822,LH0823,LH571,LH0844,LH0846,LH0866,LH 0571 ,LH1571,LH1571,LH1034,LH1044

LH1046,LH1066,LH1088,LH1222,LH1223,LH1234,LH1244,LH1246,LH1266,LH1288,LH1622 LH1623,LH1634,LH1644,LH1646,LH1666,LH1688,LH2571,LH2571,LH2034,LH2044,LH2046 LH2066,LH2088,LH2422,LH2423,LH2434,LH2444,LH2446,LH2466,LH2488,LH2822,LH2823 LH2834,LH2844,LH2846,LH2866,LH2888,LH3222,LH3223,LH3234,LH3244,LH3246,LH3266 LH3288,LH4571,LH4571,LH4034,LH4044,LH4046,LH4066,LH4088 |

| FL Series | FL644,FL666,FL688,FL523,FL844,FL922,FL944,FL945,FL956,FL966,FL988 |

| We also carry out OEM according to your requirements |

|

Detailed Photos

Product Parameters

Our Advantages

Company Advantages:

– Own Import & Export License

– TV trademark registered successfully in multiple countries

– Sales network covering China and exporting to 65 countries CHINAMFG

Membership:

– Member of China General Machine Components Industry Association

– Member of China Chain Transmission Association

– Member of China Chain Standardization Association

– Member of China Agricultural Association Machinery Manufacturers

With our highly trained staff and workers, advanced and efficient equipment, extensive sales network, and strict quality assurance systems, you can be confident that our premium qualified chain meets the highest standards and specifications.

Contact us now for more information on how TransVision products can fulfill your industry’s demands at competitive prices.

Quality First, Clients Uppermost.

Product Description:

HangZhou Vision Chain Transmission Co., Ltd. presents the Industrial Drive Roller Conveyor Leaf Chain Hoisting Hollow Pin Heavy Duty Stainless Steel Short Double Pitch (AL BL LL). This transmission chain is designed for various applications and is made of high-quality materials. With its durable construction and excellent performance, it ensures reliable and efficient operation.

Key Features:

– Suitable for transmission chain applications

– Made of high-quality materials

– Surface treatment: Other

Don’t miss out on the opportunity to enhance your operations with our top-notch chain. Contact us now for more information and take advantage of our competitive pricing.

HangZhou Vision Chain Transmission Co., Ltd. offers a range of industrial drive roller conveyor leaf chains. These chains are heavy-duty, stainless steel, and designed for hoisting and transmission purposes. Choose from various types, including AL, BL, and LL chains. Perfect for conveyor systems and other applications.

| WHY CHOOSE US |

Product Description

Introducing our comprehensive product portfolio from HangZhou Vision Chain Transmission Co., Ltd. We are proud to offer a wide range of power transmission products to meet all your needs. Our product lineup includes drive chains, conveyor chains, agricultural chains, sprockets, and couplings. With our one-stop shopping experience, you can easily find what you’re looking for with just 1 click, saving you time and effort.

Our products are the perfect combination of quality and affordability. We understand the importance of staying within your budget, and that’s why we offer value choice products that deliver exceptional performance without breaking the bank.

When you choose us, you’ll have the support of our seasoned sales associates and engineers. Our team consists of 15 experienced sales associates and 5 knowledgeable engineers who are always ready to lend a helping hand. With their industry know-how, they can provide you with expert advice and assistance. You can count on them to respond to your requests within 24 hours.

Our commitment to customer satisfaction is evident in our 100% customer retention rate. Our regular customers from overseas keep coming back not only for our premium quality products but also for the superior services we’ve provided over the years.

Experience the difference with HangZhou Vision Chain Transmission Co., Ltd. Choose us for all your power transmission needs and enjoy the convenience, quality, and excellent service we offer. Shop now and discover why we are the preferred choice for customers worldwide.

| FAQ |

| Q1: What’s your average lead time? A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate. Q2: Is your price better than your competitors given the same quality? Q4: Can we inspect the goods before shipment? Q5: What kind of payment method is acceptable for your mill? Q6: What if I have any other questions? |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Natural |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the future trends and advancements in industrial chain technology?

Industrial chain technology is continuously evolving to meet the changing needs of various industries. Here are some future trends and advancements that can be observed in industrial chain technology:

- Increased Automation: Industrial chains are becoming an integral part of automated systems. The advancement of robotics, IoT (Internet of Things), and artificial intelligence is driving the integration of industrial chains with smart technologies. This includes features such as remote monitoring, predictive maintenance, and real-time data analysis for optimizing chain performance and overall system efficiency.

- Improved Materials and Coatings: Ongoing research and development efforts are focused on developing advanced materials with enhanced properties for industrial chains. This includes materials with superior strength, durability, corrosion resistance, and wear resistance. Additionally, the development of advanced surface coatings and treatments further enhances the performance and lifespan of industrial chains.

- Energy Efficiency: Energy efficiency is a growing concern in industrial applications. Future industrial chains are likely to incorporate designs and features that reduce energy consumption, such as optimized chain profiles, reduced friction coatings, and improved lubrication systems. These advancements aim to minimize power losses and improve overall system efficiency.

- Integration with Digital Technologies: Industrial chains are expected to be increasingly integrated with digital technologies for seamless communication and data exchange. This integration enables better monitoring of chain performance, real-time diagnostics, and the ability to make data-driven decisions for maintenance and optimization. Digital twins, virtual simulations, and augmented reality (AR) are also emerging trends that allow for improved chain design, testing, and troubleshooting.

- Enhanced Safety Features: Safety remains a top priority in industrial settings. Future industrial chains may incorporate advanced safety features such as integrated sensors for detecting chain wear, overload conditions, or abnormal operating parameters. These features can provide early warning signs and help prevent accidents or equipment failures.

The future of industrial chain technology is driven by the need for increased efficiency, reliability, and safety. The integration of smart technologies, improved materials, energy efficiency measures, digitalization, and enhanced safety features are expected to shape the advancements in industrial chain technology in the coming years.

What are the common causes of industrial chain failures?

Industrial chain failures can occur due to various factors:

- Excessive load: Applying a load that exceeds the chain’s capacity can lead to stress and failure. It is important to consider the chain’s rated load and choose the appropriate chain for the application.

- Inadequate lubrication: Insufficient or improper lubrication can result in increased friction and wear, leading to premature chain failure. Regular lubrication with the recommended lubricant and following the manufacturer’s guidelines is crucial.

- Improper tensioning: Incorrect chain tension can cause misalignment, premature wear, and failure. Proper tensioning ensures optimal performance and longevity of the chain.

- Misalignment: Poor alignment between the sprockets can cause the chain to wear unevenly and increase the risk of failure. Proper alignment of the sprockets is essential for smooth operation.

- Wear and tear: Continuous use without proper maintenance and regular inspection can result in chain fatigue, elongation, and eventual failure. Regular inspection and timely replacement of worn-out components are necessary to prevent failure.

- Corrosion: Exposure to corrosive environments can weaken the chain material and compromise its integrity. Using corrosion-resistant chains or applying appropriate coatings can mitigate the risk of corrosion-related failures.

- Lack of maintenance: Neglecting routine maintenance tasks such as cleaning, lubrication, and inspection can lead to chain degradation and eventual failure. Regular maintenance is essential to ensure optimal chain performance and longevity.

How can you prevent industrial chain failures?

Preventing industrial chain failures requires proactive maintenance and proper care. Here are some key steps to prevent chain failures:

- Regular Inspection: Conduct regular inspections of the chain, sprockets, and other components to identify signs of wear, damage, or misalignment. Inspect for proper lubrication and tension as well.

- Lubrication: Ensure proper lubrication of the chain to reduce friction, wear, and corrosion. Use the recommended lubricant and follow the manufacturer’s guidelines for lubrication intervals.

- Tension Adjustment: Maintain proper chain tension to prevent excessive slack or tightness. Improper tension can cause accelerated wear and premature failure. Refer to the manufacturer’s specifications for correct tensioning procedures.

- Sprocket Alignment: Ensure proper alignment of the sprockets to prevent excessive wear on the chain. Misalignment can lead to uneven loading and premature failure. Align sprockets according to the manufacturer’s recommendations.

- Replacement of Worn Components: Monitor the chain for signs of wear and replace worn components, such as chains, sprockets, and bearings, promptly. Continuing to operate with worn components can lead to chain failure and potential damage to the machinery.

- Proper Storage: Store spare chains and components in a clean and dry environment to prevent corrosion and damage. Protect them from exposure to moisture, chemicals, and contaminants.

- Training and Education: Ensure that operators and maintenance personnel are trained in proper chain handling, installation, and maintenance techniques. Knowledgeable personnel can identify potential issues and take appropriate preventive measures.

By following these preventive measures, the risk of industrial chain failures can be significantly reduced. Regular maintenance, proper lubrication, and timely replacement of worn components are critical for ensuring the reliable operation and longevity of the industrial chain.

editor by CX 2024-04-16

China best Power Transmission Industrial Large Rollers Large Size Conveyor Scrapper Dryer Double Side with Attachments Flaged Roller Chain

Product Description

Product Description

Power Transmission Industrial Large Rollers Large Size Conveyor Scrapper Dryer Double Side with Attachments Flaged Roller Chain

Introducing our high-quality Power Transmission Industrial Large Rollers Large Size Conveyor Scrapper Dryer Double Side with Attachments Flaged Roller Chain. Designed to meet your specific needs, this chain is available in various pitch sizes, roller diameters, chain plate types, and pin diameters.

With pitch sizes ranging from 100mm to 200mm, you can choose the perfect size for your application. The attached plate conveyor chain, according to the provided drawing, ensures smooth and efficient operation.

Our rollers come in 3 types: small roller (S type), large roller (P type), and convex edge roller (F type). You can select the roller diameter that suits your requirements, ranging from 36mm to 120mm.

For the chain plates, we offer a variety of options. Choose from single side horizontal CHINAMFG plate attached plate, single side bent plate with ears and double holes type A2, or double side bent plate type K2. The chain plate thickness ranges from 4mm to 12mm, and the width varies from 25mm to 70mm.

Pin diameters are available in sizes of 10mm to 25mm, ensuring a secure and reliable connection.

Our M series metric conveyor chains, including the M315 model, are designed to meet industry standards. The dimensions of the M315 chain are in accordance with the standard GB8350-87. These chains can be easily matched with sprockets for seamless integration into your system.

Trust HangZhou Vision Chain Transmission Co., Ltd. for all your power transmission needs. Our Power Transmission Industrial Large Rollers Large Size Conveyor Scrapper Dryer Double Side with Attachments Flaged Roller Chain is made of high-quality alloy material and features a hollow chain structure. The electroplating surface treatment ensures durability and longevity.

Order our Power Transmission Industrial Large Rollers Large Size Conveyor Scrapper Dryer Double Side with Attachments Flaged Roller Chain today and experience reliable and efficient power transmission in your operations.

Product Attribute

| Product Name | Conveyor Chians |

| Available materials | carbon steel, alloy steel,stainless steel |

| OEM customisation according to your requirements | |

| Surface Treatment | Shot peening, Zinc-plated, Nickel-plated, Anodized, etc. |

| Performance | High temperature resistant Abrasion resistant |

| Reference standards | ISO,DIN,ANSL |

| Customised drawings | YES |

| Certificates | ISO9001:2008 SGS brand TV |

| Delivery time | 20 days for samples. 45 days for official order. |

| Packaging | Plastic Bag + Cardboard Box + Wooden |

Product Parameters

Our Advantages

Company Advantages:

At HangZhou Vision Chain Transmission Co., Ltd., we take pride in our numerous company advantages. With our own Import & Export License, our TV trademark has been successfully registered in multiple countries. Our sales network spans across China, and our products are exported to 65 countries across 5 continents. This global reach allows us to serve customers all around the world.

Membership:

We are proud members of several prestigious associations, including the China General Machine Components Industry Association, the China Chain Transmission Association, the China Chain Standardization Association, and the China Agricultural Association Machinery Manufacturers. These memberships demonstrate our commitment to CHINAMFG and our dedication to staying at the forefront of our industry.

With our highly trained staff and workers, advanced and efficient equipment, and a comprehensive sales network, we have the confidence to deliver premium quality chains that meet the strictest specifications and quality standards. Our commitment to quality is unwavering, and we always put our clients’ needs first.

If you would like more information on how TransVision products can meet the demands of your industry at highly competitive pricing, please do not hesitate to contact us. We are here to provide you with the best solutions for your power transmission needs.

Quality First, Clients Uppermost.

Product Categories

HangZhou Vision Chain Transmission Co., Ltd. offers a wide range of power transmission industrial products. Our selection includes large rollers, conveyor chains with attachments, double-sided chains, and more. Our chains are made from high-quality alloy and feature a hollow structure. They are electroplated for added durability. Explore our collection of conveyor, steel, and stainless steel chains, perfect for various applications in the automotive industry and beyond.

Why Choose Us

At HangZhou Vision Chain Transmission Co., Ltd., we offer a comprehensive product portfolio that includes a wide range of power transmission products. From drive chains to leaf chains, conveyor chains to agricultural chains, sprockets to couplings, we have everything you need in 1 convenient place. With our one-store-for-all shopping experience, you can significantly reduce your searching costs and find exactly what you’re looking for with just 1 click.

Value Choice Products

Our products are the perfect combination of quality and price. We understand that staying within your budget is important, which is why we offer products that meet your needs without compromising on quality. With us, you can get the best value for your money.

Seasoned Sales Associates and Engineers

Our team consists of 15 seasoned sales associates and 5 engineers who are always ready to lend a helping hand. They are well-trained with industry know-how and will respond to your requests within 24 hours. Whether you need assistance with product selection or technical support, our team is here to provide you with the guidance you need.

100% Customer Retention Rate

Our regular customers from overseas keep coming back not only for our premium quality products but also for the superior services we have provided over the years. We take pride in our 100% customer retention rate, which is a testament to the trust and satisfaction our customers have in our products and services.

Product Description

Introducing our Power Transmission Industrial Large Rollers Large Size Conveyor Scraper Dryer Double Side with Attachments Flanged Roller Chain. This high-quality chain is designed for use in conveyor systems, providing reliable and efficient power transmission.

With its alloy material and hollow chain structure, this chain offers exceptional strength and durability. The electroplating surface treatment ensures resistance to corrosion, extending the lifespan of the chain.

Whether you need a chain for a conveyor, dryer, or scraper application, this chain is the perfect choice. Its double-sided design with attachments allows for versatile use in various industrial settings.

Choose our Power Transmission Industrial Large Rollers Large Size Conveyor Scraper Dryer Double Side with Attachments Flanged Roller Chain for a reliable and cost-effective solution. Experience the quality and value that HangZhou Vision Chain Transmission Co., Ltd. is known for.

FAQ

Q1: What is the average lead time for your products?

A: Our lead time can vary, but on average, it takes 1-2 months for us to complete the entire process. However, if you have an urgent order, we also offer express shipments to ensure prompt delivery. For more detailed information, please feel free to consult our knowledgeable sales associate.

Q2: Are your prices more competitive than those of your competitors, while maintaining the same level of quality?

A: Absolutely! We take pride in offering the most competitive prices in the power transmission industry. If you happen to find a price difference, we are more than happy to match it. Our goal is to provide you with the best value for your money.

Q3: Can you manufacture chains based on my CAD drawings?

A: Yes, we can! In addition to our standard chains, we specialize in producing non-standard and custom-designed products to meet your specific technical requirements. In fact, a significant portion of our production capacity is dedicated to manufacturing these unique products.

Q4: Can we inspect the goods before they are shipped?

A: Certainly! We understand the importance of quality assurance. You, your representative, or any third-party inspection party you assign are welcome to visit our facility and conduct a thorough inspection of the goods.

Q5: What payment methods do you accept?

A: We are flexible when it comes to payment methods. We accept T/T, L/C, and various other online payment methods that are applicable to your situation. Our aim is to make the payment process as convenient as possible for you.

Q6: If I have any further questions, how can I get in touch with you?

A: Whenever you have any doubts or inquiries, please don’t hesitate to reach out to our dedicated sales associate. They are always available to assist you and ensure that all your questions are answered to your satisfaction.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy |

|---|---|

| Structure: | Hollow Chain |

| Surface Treatment: | Electroplating |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can an industrial chain be used for heavy-duty applications?

Yes, an industrial chain is commonly used in heavy-duty applications due to its ability to handle high loads and provide reliable power transmission. Here are some detailed reasons why industrial chains are suitable for heavy-duty applications:

- High Load Capacity: Industrial chains are designed to withstand heavy loads and transmit power efficiently. They are constructed with robust materials and components to ensure they can handle the demanding conditions of heavy-duty applications.

- Strength and Durability: Industrial chains are manufactured from high-strength materials such as alloy steel, which provides exceptional tensile strength and resistance to wear and fatigue. This allows them to withstand the stresses and strains associated with heavy loads and continuous operation.

- Reliable Power Transmission: Industrial chains offer a reliable and efficient means of transmitting power in heavy-duty applications. They provide a positive engagement between the sprockets, ensuring smooth and consistent power transfer even under high loads.

- Versatility: Industrial chains can be designed and configured to meet the specific requirements of different heavy-duty applications. They are available in various sizes, designs, and types, allowing for customization and adaptation to specific load conditions and operating environments.

- Proven Track Record: Industrial chains have been widely used in heavy-duty applications across industries such as construction, mining, agriculture, and material handling. Their reliability and performance in demanding conditions have been well-documented, making them a trusted choice for heavy-duty applications.

Overall, the robust construction, high load capacity, strength, durability, and proven performance make industrial chains a suitable choice for heavy-duty applications where reliable power transmission and handling of high loads are essential.

Can an industrial chain be used for vertical lifting applications?

Yes, industrial chains can be used for vertical lifting applications. However, several factors need to be considered to ensure safe and efficient lifting operations:

- Chain type and strength: The industrial chain selected for vertical lifting applications must have the appropriate strength and load capacity to safely lift the intended load.

- Safety factors: It is crucial to consider the safety factors and ensure that the selected chain is capable of handling the maximum expected load without exceeding its rated capacity.

- Overhead clearance: Sufficient overhead clearance is necessary to accommodate the length of the chain and prevent any obstructions during the lifting process.

- Proper tensioning: The chain must be properly tensioned to prevent slippage or excessive slack, which can compromise the lifting operation.

- Guidance and control: Proper guidance and control mechanisms should be in place to ensure smooth and controlled vertical movement of the load.

- Maintenance and inspection: Regular maintenance and inspection of the chain are essential to identify any signs of wear, damage, or fatigue that may compromise its integrity and lifting capability.

It is important to consult industry standards, regulations, and specific manufacturer guidelines to determine the suitability of an industrial chain for a vertical lifting application. Additionally, working with experienced professionals and following established safety protocols is crucial to ensure the safe and effective use of the industrial chain in lifting operations.

How do you troubleshoot common issues with industrial chains?

Troubleshooting common issues with industrial chains involves identifying the problem, determining its cause, and taking appropriate corrective actions. Here are some common issues and troubleshooting steps:

- Chain misalignment: If the chain is misaligned, it can cause excessive wear, noise, and tension issues. To troubleshoot this, visually inspect the chain’s alignment and check if the sprockets are properly aligned. Adjust the sprockets and ensure they are aligned with the chain’s centerline.

- Chain elongation: Over time, industrial chains can elongate, leading to poor performance and increased stress on the components. To troubleshoot elongation, measure the chain’s pitch and compare it to the manufacturer’s specifications. If the chain is elongated beyond the recommended limit, it may need to be replaced.

- Inadequate lubrication: Insufficient or improper lubrication can result in increased friction and wear. Check the lubrication system and ensure the chain is properly lubricated according to the manufacturer’s recommendations. Adjust the lubrication schedule or consider using a different lubricant if necessary.

- Excessive chain tension: Excessive tension can cause increased wear, noise, and strain on the chain and components. Check the tension of the chain and adjust it to the manufacturer’s recommended specifications. Ensure proper tensioning devices, such as tensioners or idler sprockets, are in place and functioning correctly.

- Broken or damaged links: If there are broken or damaged links in the chain, they can cause performance issues and potential failure. Inspect the chain for any visible damage, such as broken pins or links, and replace the affected components as necessary.

- Excessive chain wear: Excessive wear can lead to chain elongation, decreased performance, and increased risk of failure. Regularly inspect the chain for signs of wear, such as elongation, worn sprocket teeth, or excessive clearance between the chain and sprockets. Replace the chain if it has reached its wear limit.

It is important to consult the manufacturer’s guidelines and recommendations for troubleshooting specific issues with the particular type of industrial chain being used. Additionally, regular maintenance, including proper lubrication, tensioning, and periodic inspections, can help prevent common issues and prolong the lifespan of the industrial chain.

editor by CX 2024-01-11

China best Double hole industrial chain P100 roller plus side conveyor chain Double hole stainless steel chain

Product Description

Double hole industrial chain P100 roller plus side conveyor chain Double hole stainless steel chain

Product introduction

| Material | Stainless steel |

| Surface Treatment | Polishing,Original Colour,Polishing |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery ……… |

| Standard or Nonstandard | Standard |

| Heat Treatment: | High Temperature Hardening |

| Color | Elf,dark yellow,dark blue,black |

| Features |

•Large reduction ratio (usually up to 1:7) |

Chain Plate

Heat treated carbon/alloy steels are used for high tensile strength.Shot peening process to improve fatigue resistance.

Roller

Hardened carbon/alloy steels are used for excellent wear resistance and rigidity.Shot peening process to improve fatigue resistance.

Bush

Case hardened alloy steels with external and internal hardened surfaces are used for high wear resistance and are accurately set into link plates.

Pin

Alloy steels are used for high wear resistance and toughness.Surface hardening is applicable request.

Green Power Industry Co Llimited is an international export enterprise combined with factory specializing in the manufacturing of brake system , clutch system,spark plug and chain . Our company is a professional manufacturer and supplier of brake,chain and clutch in China. We both have our own brake CHINAMFG factory, brake pad factory, brake shoe factory ,clutch disc factory,chain factory, spark plug factory .We focus on developing high-quality products for OEM market ,Our company have developed and produced high quality brake in formula non -metallic and asbestos free for automobile and brake shoe assembly for heavy duty truck . The production are noted good characteristics such as high strength , high heat-resisting , wear-resisting.low dust virtue ,no noise and better stability . The series products had been exporting to North -America ,Europe ,Middle -East ,Australia and etc, widely sale to domestic OEM factories and aftermarket.

Our company is composed of professional team , process advanced production inspection and testing equipment Each product have passed the first inspection, process inspection, error prevention, and laboratory tests to ensure that each piece of qualified products sent to customers

We are determined to set up the aim of “excellent quality and satisfying service·, with·the first class quality , reasonable price and perfect service . we set strick demand and operate conforming to the standard to guarantee all the products can be meet our customer’s needs

1.Q: What is the certificate of your factory?

A: We have passed IAF ISO and TS16949 certification.

2.Q: Can it be produced according to the sample?

A: Yes, we can produce through your samples or technical drawings. We can build molds and fixtures.

3.Q: Do you test all products before shipping?

A: Yes, we conduct 100% quality testing before delivery, and we are 100% responsible for product quality.

4.Q: What is your delivery time?

A:If we have stock, we can send it immediately within a week. If not, it usually ranges from 7 days to 35 days, depending on the quantity.

5.Q: What is your sample policy?

A: We want to provide you with samples for approval. There will be no charge for 1 or 2 samples, but the customer needs to bear the courier fee first.

It will be drawback to customer when order placed

6.Q: How do you make our business establish a long-term good cooperative relationship?

A:1. We maintain excellent quality and competitive prices to ensure that our customers benefit;

2. We respect every customer as our friend, we do business sincerely and make friends widely,No matter where they come from.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain, Conveyor Chain |

|---|---|

| Material: | Stainless steel |

| Surface Treatment: | Polishing |

| Feature: | Heat Resistant |

| Chain Size: | 1/2"*3/32" |

| Structure: | Roller Chain |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does lubrication affect the performance of an industrial chain?

Lubrication plays a crucial role in the performance and longevity of an industrial chain. It provides a protective layer between the moving components of the chain, reducing friction and wear. Here are the key ways in which lubrication affects the performance of an industrial chain:

- Friction reduction: Lubrication creates a lubricating film that reduces friction between the chain’s pins, bushings, and rollers. This minimizes the resistance to movement and allows the chain to operate smoothly, reducing energy consumption and preventing excessive heat generation.

- Wear prevention: Lubrication forms a protective barrier that prevents direct metal-to-metal contact between the chain’s components. This reduces wear and extends the chain’s service life, minimizing the need for frequent replacements and costly downtime.

- Corrosion protection: Lubricants can have anti-corrosion additives that protect the chain from rust and corrosion caused by moisture, chemicals, or environmental factors. This is particularly important in applications exposed to harsh or corrosive environments.

- Noise reduction: Proper lubrication reduces the noise generated by the chain’s movement by minimizing metal-to-metal contact and damping vibrations. This is crucial in applications where noise levels need to be controlled, such as in residential areas or noise-sensitive environments.

- Temperature control: Lubrication helps dissipate heat generated during chain operation, preventing overheating and potential damage to the chain. It also provides thermal stability, allowing the chain to maintain its performance even in high-temperature environments.

- Contamination resistance: Lubrication helps repel and flush away contaminants such as dirt, dust, and debris that can accumulate on the chain. By keeping the chain clean, lubrication reduces the risk of abrasive wear and blockages that can hinder the chain’s operation.

Proper lubrication selection and maintenance are critical to ensure optimal performance and longevity of an industrial chain. It is important to follow the manufacturer’s recommendations regarding lubrication intervals, lubricant type, and application methods to achieve the best results.

How do you select the appropriate lubricant for an industrial chain?

Selecting the right lubricant for an industrial chain is crucial to ensure its smooth operation, reduce wear, and extend its lifespan. Here are the key factors to consider when choosing the appropriate lubricant:

1. Chain type: Different types of industrial chains may have specific lubrication requirements. Refer to the manufacturer’s recommendations or technical specifications to determine the compatible lubricant.

2. Operating conditions: Consider the operating environment, such as temperature, humidity, and exposure to contaminants like dust or chemicals. Choose a lubricant that can withstand the specific conditions and provide adequate protection.

3. Load and speed: Evaluate the load capacity and speed of the chain system. High loads or high speeds may require lubricants with enhanced film strength and viscosity to prevent metal-to-metal contact.