Product Description

Product Description

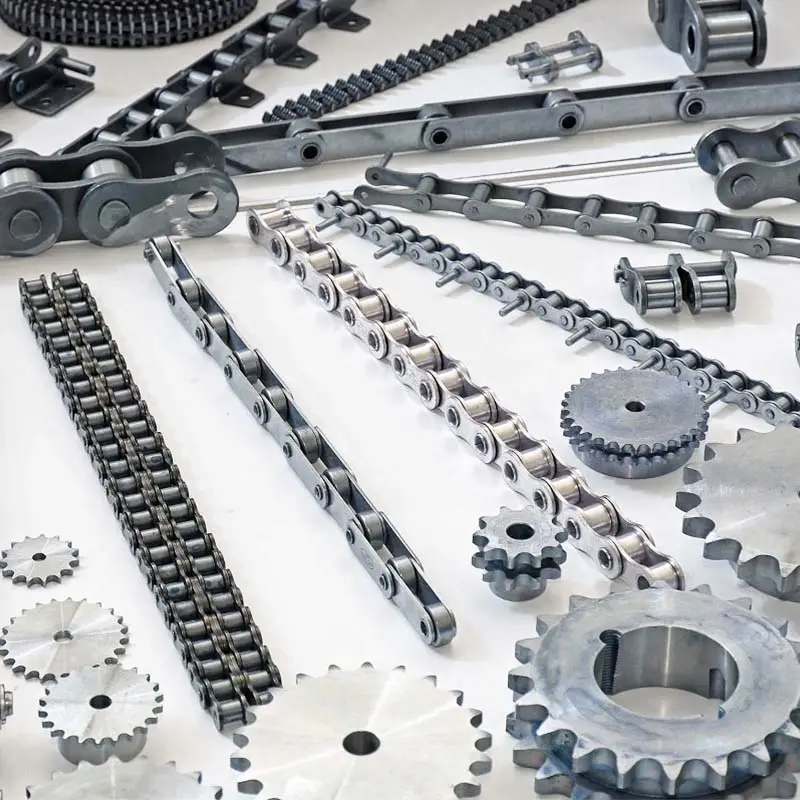

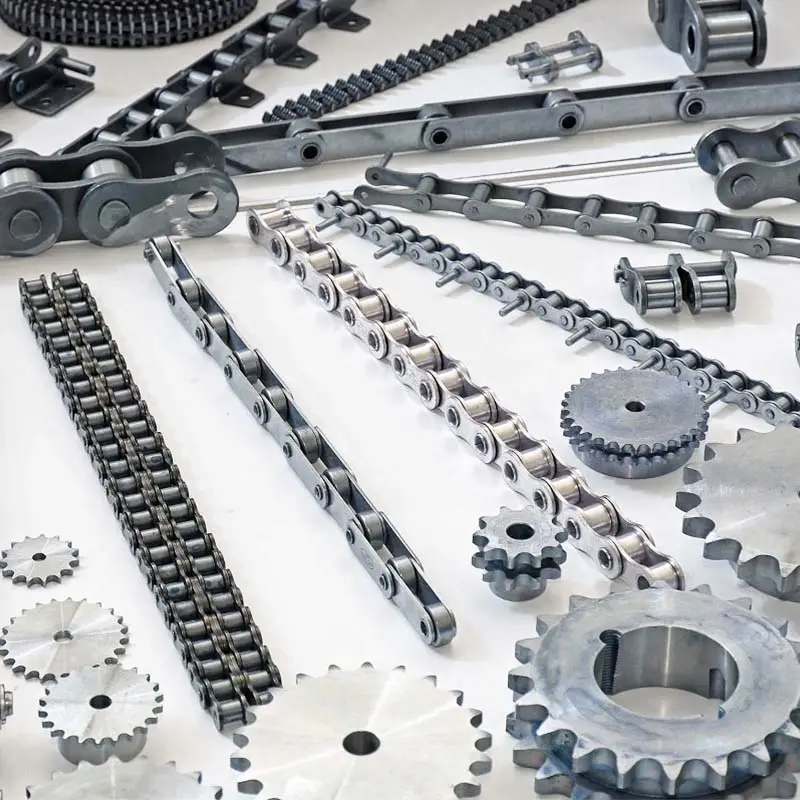

Vision Group is 1 of the largest manufacturers of Driving Chain, Conveyor Chain, Motorcycle Chain, Hoisting Chain, Agriculture Chain, Stainless Steel Chain, Dropped Forged Rivetless Chain, Long Pitch Conveyor Chain and so on.

GB/T, DIN, ANSI, ISO, BS, JIS.

ISO9001: 2000 and ISO1400: 2004.

Product Attribute

| Product name | Transmission Standard Roller Chain |

|

Surface Treatment |

Shot Peening ,Tempering Oiling ,Nickel-plated Grease, zince plated, Heat Treatment ,Stain proofing Carburizing ,Pre-stretched and anti-fatigue ,Quenching |

| Product application | Industry machine,Agriculture, mining, metallurgy, petrochemical industry, lifting and transportation and other industries |

| Product Series |

Series A, Series B, Heavy Duty |

| material |

Stainless steel and carbon steel |

| structure |

Simplex/Duplex/Triplex |

| Port |

Any sea port or airport in China |

| Brand | TV OEM |

| Payment |

L/C, T/T, D/P, Western Union |

| Package |

Chain, Plastic Bag, Color Box, Wooden Case. or OEM |

| A Series | 03C,04C-1,06C-1,085-1,08A-1,10A-1,12A-1,16A-1,20A-1,24A-1,28A-1,32A-1,36A-1,40A-1,48A-1.

15,25,35,41,40,50,60,80,100,120,140,160,180,200,240 |

| 04C-2,06C-2,085-2,08A-2,10A-2,12A-2,16A-2,20A-2,24A-2,28A-2,32A-2,36A-2,40A-2,48A-2.

25-2,35-2,41-2,40-2,50-2,60-2,80-2,100-2,120-2,140-2,160-2,180-2,200-2,240-2. |

|

| 04C-3,06C-3,085-3,08A-3,10A-3,12A-3,16A-3,20A-3,24A-3,28A-3,32A-3,36A-3,40A-3,48A-3.

25-3,35-3,41-3,40-3,50-3,60-3,80-3,100-3,120-3,140-3,160-3,180-3,200-3,240-3. |

|

| B Series | 05B-1,06B-1,08B-1,10B-1,12B-1,16B-1,20B-1,24B-1,28B-1,32B-1,40B-1,48B-1,56B-1,64B-1,72B-1. |

| 05B-2,06B-2,08B-2,10B-2,12B-2,16B-2,20B-2,24B-2,28B-2,32B-2,40B-2,48B-2,56B-2,64B-2,72B-2. |

|

| 05B-3,06B-3,08B-3,10B-3,12B-3,16B-3,20B-3,24B-3,28B-3,32B-3,40B-3,48B-3,56B-3,64B-3,72B-3. |

|

| Heavy Duty | 08AH-1,10AH-1,12AH-1,16AH-1,20AH-1,24AH-1,28AH-1,32AH-1,36AH-1,40AH-1,48AH-1

35H,40H,50H,60H,80H,100H,120H,140H,160H,180H,200H,240H |

| 12AH-2,16AH-2,20AH-2,24AH-2,28AH-2,32AH-2,40AH-2,

35H-2,40H-2,50H-2,60H-2,80H-2,100H-2,120H-2,140H-2,160H-2,180H-2,200H-2,240H-2. |

|

| 12AH-3,16AH-3,20AH-3,24AH-3,28AH-3,32AH-3,40AH-3

35H-3,40H-3,50H-3,60H-3,80H-3,100H-3,120H-3,140H-3,160H-3,180H-3,200H-3,240H-3. |

|

| Double pitch Series |

208A,208B,210A,210B,212A,212B,216A,216AH,216B,220A,220B,224A,224B,228B,232B

2040,2050,2060,2080,2080H,2100,2120 |

| We also carry out OEM according to your requirements | |

Product Parameters

Our Advantages

Company advantages:

Own Import & Export License, The TV trade mark registered successfully in many countries, Sales network spread all over China, Products export to 65 countries in 5 continents.

Membership:

1. The member of China General Machine Components Industry Association.

2. The member of China Chain Transmission Association.

3. The member of China Chain Standardization Association.

4. The member of China Agricultural Association Machinery Manufacturers.

With our excellent trained staffs and workers, advanced and efficient equipments, completely sales network, strict QA systems. You are confidence that our premium qualified chain can meet all customers’ specification and strictest quality standards.

WHY CHOOSE US

Comprehensive Product Portfolio We produce and supply a wide range of power transmission

products including drive chains, leaf chains, conveyor chains, agricultural chains, sprockets, and

couplings. This one-store-for-all shopping experience will significantly reduce your searching costs while

guarantee youfind what you want at 1 click.

Value Choice Products Our products are the best combination of quality and price, and you get what

you want within your budgets

Seasoned Sales Associates and Engineers We have 15 seasoned sales associates and 5 engineers;

on our team at your disposal any time when you need a helping hand. They are well trained with industry

know-now and will always respond to your requests within 24 hours.

100% Customer Retention Rate Our regular customers from overseas come back not just for our

premium quality products, but for the superior services that we’ve provided over the years.

FAQ

Q1: What’s your average lead time?

A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate.

Q2: Is your price better than your competitors given the same quality?

A: Definitely YES. We provide the most competitive price in the power transmission industry. If price disparity exists, we’ll be more than happy to do a price match.

Q3: Can you make chains according to my CAD drawings?

A: Yes. Besides the regular standard chains, we produce non-standard and custom-design products to meet the specific technical requirements. In reality, a sizable portion of our production capacity is assigned to make non-standard products.

Q4: Can we inspect the goods before shipment?

A: Yes. You or your representative or any third-party inspection party assigned is allowed access to our facility and do the inspection.

Q5: What kind of payment method is acceptable for your mill?

A: We’re flexible. We take T/T, L/C, or any other online payment methods so long as it’s applicable for you.

Q6: What if I have any other questions?

A: Whenever in doubt, you’re always encouraged to consult our sales associate any time – They will help you to your satisfaction.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Polishing |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can an industrial chain be retrofitted to an existing conveyor system?

Yes, an industrial chain can be retrofitted to an existing conveyor system in many cases. Retrofitting involves replacing the existing conveyor belt or alternative power transmission system with an industrial chain to improve performance, increase load capacity, or meet specific application requirements. Here are the key considerations for retrofitting an industrial chain:

- System compatibility: Before retrofitting, it is essential to evaluate the compatibility of the existing conveyor system with an industrial chain. Consider factors such as the structure, design, and components of the conveyor system to ensure proper fit and functionality.

- Chain selection: Choose an industrial chain that is suitable for the specific application requirements and aligns with the load capacity, speed, and environmental conditions of the conveyor system. Consider factors such as chain type, pitch, material, and lubrication requirements.

- Drive system adaptation: Retrofitting an industrial chain may require adjustments to the drive system of the conveyor. This may involve replacing the existing drive components or modifying the drive mechanism to accommodate the chain drive.

- Installation and alignment: Proper installation and alignment of the industrial chain are crucial for optimal performance. Ensure that the chain is tensioned correctly, aligned with the sprockets, and properly lubricated.

- Maintenance and monitoring: Implement a maintenance plan to regularly inspect and lubricate the industrial chain. Monitor the chain’s performance, including tension, wear, and any signs of failure, to ensure smooth and efficient operation.

- Safety considerations: Retrofitting an industrial chain requires adherence to safety standards and guidelines. Ensure that the retrofitting process does not compromise the safety of personnel or the integrity of the conveyor system.

It is recommended to consult with an experienced engineer or conveyor system specialist when retrofitting an industrial chain to an existing conveyor system. They can provide expert advice, conduct a thorough assessment, and ensure a successful retrofit that improves the performance and reliability of the conveyor system.

What is the load capacity of an industrial chain?

An industrial chain’s load capacity refers to the maximum amount of weight or force it can safely withstand without experiencing failure or damage. The load capacity of an industrial chain depends on several factors, including its design, construction, material, and size.

Industrial chains are engineered and manufactured to handle a wide range of load capacities, from light-duty applications to heavy-duty industrial operations. The load capacity of a specific industrial chain is typically provided by the manufacturer and can be found in product specifications or technical documentation.

The load capacity of an industrial chain is influenced by various factors, such as:

- Chain Type and Size: Different chain types, such as roller chains, silent chains, or engineering steel chains, have varying load capacities. Additionally, the size or pitch of the chain also affects its load capacity, with larger chains generally having higher load capacities.

- Chain Material and Construction: The material used to construct the chain, such as stainless steel, carbon steel, or alloy steel, affects its strength and load-bearing capacity. The chain’s construction, including the number and arrangement of links, also plays a role in determining its load capacity.

- Operating Conditions: The environment in which the industrial chain operates, such as temperature, humidity, and exposure to chemicals or corrosive substances, can impact its load capacity. Extreme conditions may require special chains with higher load ratings.

- Application Requirements: The specific application and the forces involved, such as tension, shock loads, or dynamic forces, need to be considered when determining the appropriate load capacity of an industrial chain.

To ensure the safe and efficient operation of an industrial chain, it is crucial to select a chain with an appropriate load capacity for the intended application. Exceeding the recommended load capacity can lead to premature wear, chain failure, or safety hazards. Consulting the manufacturer’s specifications and guidelines, as well as engineering calculations, can help determine the suitable load capacity for a given industrial chain.

How can you prevent industrial chain failures?

Preventing industrial chain failures requires proactive maintenance and proper care. Here are some key steps to prevent chain failures:

- Regular Inspection: Conduct regular inspections of the chain, sprockets, and other components to identify signs of wear, damage, or misalignment. Inspect for proper lubrication and tension as well.

- Lubrication: Ensure proper lubrication of the chain to reduce friction, wear, and corrosion. Use the recommended lubricant and follow the manufacturer’s guidelines for lubrication intervals.

- Tension Adjustment: Maintain proper chain tension to prevent excessive slack or tightness. Improper tension can cause accelerated wear and premature failure. Refer to the manufacturer’s specifications for correct tensioning procedures.

- Sprocket Alignment: Ensure proper alignment of the sprockets to prevent excessive wear on the chain. Misalignment can lead to uneven loading and premature failure. Align sprockets according to the manufacturer’s recommendations.

- Replacement of Worn Components: Monitor the chain for signs of wear and replace worn components, such as chains, sprockets, and bearings, promptly. Continuing to operate with worn components can lead to chain failure and potential damage to the machinery.

- Proper Storage: Store spare chains and components in a clean and dry environment to prevent corrosion and damage. Protect them from exposure to moisture, chemicals, and contaminants.

- Training and Education: Ensure that operators and maintenance personnel are trained in proper chain handling, installation, and maintenance techniques. Knowledgeable personnel can identify potential issues and take appropriate preventive measures.

By following these preventive measures, the risk of industrial chain failures can be significantly reduced. Regular maintenance, proper lubrication, and timely replacement of worn components are critical for ensuring the reliable operation and longevity of the industrial chain.

editor by CX 2024-04-29

China wholesaler Drive conveyor chain outer curved plate chain stainless steel heavy-duty chain For Industrial

Product Description

Drive conveyor chain outer curved plate chain stainless steel heavy-duty chain For Industrial

Product introduction

| Material | Stainless steel |

| Surface Treatment | Polishing,Original Colour,Polishing |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery ……… |

| Standard or Nonstandard | Standard |

| Heat Treatment: | High Temperature Hardening |

| Color | Elf,dark yellow,dark blue,black |

| Features |

•Large reduction ratio (usually up to 1:7) |

Chain Plate

Heat treated carbon/alloy steels are used for high tensile strength.Shot peening process to improve fatigue resistance.

Roller

Hardened carbon/alloy steels are used for excellent wear resistance and rigidity.Shot peening process to improve fatigue resistance.

Bush

Case hardened alloy steels with external and internal hardened surfaces are used for high wear resistance and are accurately set into link plates.

Pin

Alloy steels are used for high wear resistance and toughness.Surface hardening is applicable request.

Green Power Industry Co Llimited is an international export enterprise combined with factory specializing in the manufacturing of brake system , clutch system,spark plug and chain . Our company is a professional manufacturer and supplier of brake,chain and clutch in China. We both have our own brake CHINAMFG factory, brake pad factory, brake shoe factory ,clutch disc factory,chain factory, spark plug factory .We focus on developing high-quality products for OEM market ,Our company have developed and produced high quality brake in formula non -metallic and asbestos free for automobile and brake shoe assembly for heavy duty truck . The production are noted good characteristics such as high strength , high heat-resisting , wear-resisting.low dust virtue ,no noise and better stability . The series products had been exporting to North -America ,Europe ,Middle -East ,Australia and etc, widely sale to domestic OEM factories and aftermarket.

Our company is composed of professional team , process advanced production inspection and testing equipment Each product have passed the first inspection, process inspection, error prevention, and laboratory tests to ensure that each piece of qualified products sent to customers

We are determined to set up the aim of “excellent quality and satisfying service·, with·the first class quality , reasonable price and perfect service . we set strick demand and operate conforming to the standard to guarantee all the products can be meet our customer’s needs

1.Q: What is the certificate of your factory?

A: We have passed IAF ISO and TS16949 certification.

2.Q: Can it be produced according to the sample?

A: Yes, we can produce through your samples or technical drawings. We can build molds and fixtures.

3.Q: Do you test all products before shipping?

A: Yes, we conduct 100% quality testing before delivery, and we are 100% responsible for product quality.

4.Q: What is your delivery time?

A:If we have stock, we can send it immediately within a week. If not, it usually ranges from 7 days to 35 days, depending on the quantity.

5.Q: What is your sample policy?

A: We want to provide you with samples for approval. There will be no charge for 1 or 2 samples, but the customer needs to bear the courier fee first.

It will be drawback to customer when order placed

6.Q: How do you make our business establish a long-term good cooperative relationship?

A:1. We maintain excellent quality and competitive prices to ensure that our customers benefit;

2. We respect every customer as our friend, we do business sincerely and make friends widely,No matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain, Conveyor Chain |

|---|---|

| Material: | Stainless steel |

| Surface Treatment: | Polishing |

| Feature: | Heat Resistant |

| Chain Size: | 1/2"*3/32" |

| Structure: | Roller Chain |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you ensure proper tensioning and alignment of an industrial chain drive?

Proper tensioning and alignment of an industrial chain drive are crucial for optimal performance, efficiency, and longevity of the system. Here are the steps to ensure correct tensioning and alignment:

- Tensioning:

1. Determine the manufacturer’s recommended tension for the specific industrial chain being used. This information can usually be found in the chain drive system documentation or provided by the manufacturer.

2. Measure the current tension of the chain using a tension measuring tool or gauge. This is typically done by applying a known force to a specific point on the chain and measuring the elongation or deflection.

3. Compare the measured tension with the recommended tension. If the measured tension is lower, the chain needs to be tensioned, while if it is higher, the tension needs to be reduced.

4. Adjust the tension by either increasing or decreasing the slack in the chain. This is usually done by adjusting the position of the chain tensioner or by altering the position of the chain drive components, such as the motor or sprockets.

5. Repeat the tension measurement and adjustment process until the recommended tension is achieved. It is important to ensure the tension is evenly distributed across the chain.

- Alignment:

1. Check the alignment of the chain drive components, including the motor, sprockets, and shafts. Misalignment can cause excessive wear, noise, and reduced efficiency.

2. Use alignment tools, such as laser alignment devices or straight edges, to assess the alignment of the components. The goal is to ensure that the chain runs parallel to the sprockets and that the sprockets are properly aligned with each other.

3. Make adjustments to correct any misalignment. This may involve shimming or repositioning the components to achieve proper alignment.

4. Verify the alignment by observing the chain’s movement and its interaction with the sprockets during operation. The chain should run smoothly without excessive vibration, noise, or rubbing against the sprocket teeth.

5. Regularly monitor the tension and alignment of the industrial chain drive and make necessary adjustments as part of the routine maintenance program.

Proper tensioning and alignment help minimize chain wear, reduce the risk of premature failure, and ensure smooth and efficient operation of the industrial chain drive system.

Can an industrial chain be used in high-temperature environments?

An industrial chain’s suitability for high-temperature environments depends on the specific chain type, material, and operating conditions. While some industrial chains are designed to withstand elevated temperatures, others may experience performance issues or damage when exposed to excessive heat.

Industrial chains used in high-temperature applications are typically constructed using materials that exhibit excellent heat resistance. Common materials include heat-resistant alloys, stainless steel, or specialized coatings that can withstand the elevated temperatures without compromising the chain’s strength or integrity.

When considering the use of an industrial chain in high-temperature environments, several factors should be taken into account:

- Temperature Range: Determine the maximum temperature the industrial chain will be exposed to. Different chain materials have different temperature limits, and it’s crucial to select a chain that can withstand the specific temperature range.

- Chain Type: Certain chain types, such as roller chains or silent chains, may be better suited for high-temperature applications than others. Consult the manufacturer’s guidelines and specifications to ensure the chosen chain type is suitable for the intended temperature range.

- Lubrication: Proper lubrication is essential in high-temperature environments to minimize friction, reduce wear, and ensure smooth chain operation. Special high-temperature lubricants or dry lubrication methods may be required to maintain chain performance under elevated temperatures.

- Heat Dissipation: Consider the ability of the industrial chain and the surrounding equipment to dissipate heat effectively. In some cases, additional cooling mechanisms or heat shielding may be necessary to protect the chain and prevent overheating.

- Application Requirements: Assess the specific demands of the application, such as load, speed, and cyclic operation, and ensure that the chosen industrial chain can handle these conditions at high temperatures.

It’s important to consult the manufacturer’s recommendations and technical documentation to verify the suitability of an industrial chain for high-temperature environments. Working with experienced engineers or industry experts can also provide valuable insights and guidance in selecting the appropriate chain for such applications.

What materials are commonly used in industrial chains?

Industrial chains are constructed using various materials to meet specific application requirements. The choice of material depends on factors such as load capacity, environmental conditions, corrosion resistance, and temperature resistance. Here are some commonly used materials in industrial chains:

- Carbon Steel: Carbon steel is widely used in industrial chains due to its strength, durability, and affordability. It offers good resistance to wear and can handle moderate loads in standard operating conditions.

- Alloy Steel: Alloy steels are alloyed with other elements to enhance their mechanical properties, such as increased strength, hardness, and wear resistance. Alloy steel chains are commonly used in heavy-duty applications where higher load capacities and greater toughness are required.

- Stainless Steel: Stainless steel chains are highly corrosion-resistant and are suitable for applications where exposure to moisture, chemicals, or high temperatures is a concern. They offer excellent durability and can withstand harsh environments, making them ideal for industries such as food processing, pharmaceuticals, and marine applications.

- Plastic: Plastic chains, typically made from engineering-grade polymers such as acetal or nylon, are lightweight, corrosion-resistant, and offer low friction. They are often used in applications where reduced noise, lubrication-free operation, and resistance to chemicals or moisture are desired.

- Specialty Alloys: In specific industries or applications with extreme conditions, specialty alloys such as stainless steel alloys, nickel alloys, or heat-resistant alloys may be used to provide exceptional strength, corrosion resistance, or temperature resistance.

It’s important to consider the material compatibility with the environment, load requirements, and other factors when selecting an industrial chain for a particular application. Consulting with manufacturers or industry experts can help determine the most suitable material for specific industrial chain needs.

editor by CX 2024-04-22

China Standard Manufacturer From China of Overhead Detachable Drop Forged Conveyor Chain for Slaughtering Line (X348 X458 X658 X678 X698 F100 F160)

Product Description

About Factory

With more than 18 years’ histiory, we are a professinal manufacturer for drop forged products such as forged chain (X348 X458 X658 X678 X698 F100 F160), scraper chain (10160, 14218, 14226, 142N), conveyor trolley (X348, X458, X678, XT160), and drive chain (X348, X458, X678), and so forth standard moulds of chain.

Besides, we can also produce as per your drawing or sample, special link chain, pusher, pin and plate, according to customers’ unique requirements.

Product Description

1) Material: Alloy steel, 40Cr, 42CrMo and so on.

2) Types: X348 X458 X658 X678 X698 F100 F160, and so on. (Or as per your drawing)

3) Process: Moulding→Forging→Polishing & Blasting→Fine machining→Heat treatment→Blasting→Inspecting & testing→Packing

Product Show

Technical Data

| Model | Pitch | Dimension | Lateral Corner | Standard Measured Length (mm) | Measured Quantity | Tensile Strength (KN) | Weight (Kg/m) | |||||

| A | F | G | J | K | S | |||||||

| 80H | 80 | 73 | 42 | 18.4 | 20 | 34.5 | 19.5 | 7 | 3032/3058 | 38 | 250 | 7.8 |

| X348 | 76.6 | 46 | 27 | 12.7 | 12.7 | 20.6 | 13.5 | 9 | 3050.5/3095.2 | 40 | 110 | 3.2 |

| X458 | 102.4 | 57 | 37 | 16 | 16 | 26.5 | 17.5 | 9 | 3063.1/3090.2 | 30 | 210 | 5.2 |

| 468H | 102.4 | 84.1 | 47.8 | 18 | 29.5 | 42.9 | 22.2 | 9 | 3063.1/3090.2 | 30 | 318 | 11.5 |

| X658 | 153.2 | 55.6 | 35 | 16 | 16 | 57.2 | 17.5 | 7 | 3055.1/3082.8 | 20 | 210 | 4 |

| X678 | 153.2 | 77 | 50.8 | 22.2 | 21 | 34.2 | 25 | 7 | 3055.1/3082.8 | 20 | 320 | 9.5 |

| 678 | 153.2 | 77 | 50.8 | 22.2 | 21 | 34.2 | 25 | 7 | 3055.1/3082.8 | 20 | 320 | 9.5 |

| 698 | 153.2 | 95.25 | 64 | 28 | 25.4 | 41.3 | 32 | 5 | 3055.1/3082.8 | 20 | 515 | 17 |

| 998 | 229.4 | 95.25 | 67.5 | 28 | 25.4 | 41.3 | 32 | 5 | 3205/3232.4 | 13 | 515 | 14.8 |

| 9118 | 229.4 | 123.8 | 76.2 | 35 | 33.5 | 52 | 38.1 | 5 | 3205/3232.4 | 13 | 832 | 24.2 |

| S348 | 76.6 | 38.9 | 28.6 | 12.7 | 12.7 | 20.6 | 13.5 | 9 | 3050.5/3095.2 | 40 | 110 | 3.2 |

| S458 | 102.4 | 52.1 | 35 | 16 | 16 | 26.5 | 17.5 | 9 | 3063.1/3090.2 | 30 | 210 | 5.2 |

| S678 | 153.2 | 69.8 | 50.8 | 22.2 | 21 | 34.2 | 25 | 7 | 3055.1/3082.8 | 20 | 320 | 9.5 |

| S698 | 153.2 | 73 | 68.3 | 28 | 25.4 | 41.3 | 32 | 5 | 3055.1/3082.8 | 20 | 515 | 17 |

| S9118 | 229.4 | 98.4 | 77.8 | 35 | 33.5 | 52 | 38.1 | 5 | 3205/3232.4 | 13 | 832 | 24.2 |

| F100 | 100 | 57 | 37 | 16 | 16 | 26.5 | 17.5 | 9 | 2991.3/3018.3 | 30 | 210 | 5.2 |

| F160 | 160 | 78 | 54 | 24 | 20.5 | 36 | 28 | 7 | 3190.7/3219.5 | 20 | 318 | 10.3 |

Products & Testing Equipments

Products Application

Packing & Delivery

Why Choose Us?

1. We are engaged in chain industry over 15 years with rich market experience. We keep improving production techniques. All the products have longer working life and have passed the market test.

2. We can design the correct chains with high quality material, good abrasion resistance, good corrosion, high strengthen and etc as per your request or the chain application.

3. We are the chain manufacturer; you can directly purchase the product from us with low price and high quality.

4. We have a professional team for international trade, they have abundant experiences and are always ready to solve problems for customers. So you have nothing to worry about.

5. We have the long-term cooperative forwarder who can give us the lowest freight. And it can help you to save the freight. What’s more, for the FCL, we will design the packages as per the container sizes with the largest capacity to save the shipping cost for both of us.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy |

|---|---|

| Structure: | Combined Chain |

| Surface Treatment: | Polishing |

| Chain Size: | 1/2"*11/128" |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Mould Number: | X458X348 X458 X658 X678 X698 F100 F160 |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you ensure proper tensioning and alignment of an industrial chain drive?

Proper tensioning and alignment of an industrial chain drive are crucial for optimal performance, efficiency, and longevity of the system. Here are the steps to ensure correct tensioning and alignment:

- Tensioning:

1. Determine the manufacturer’s recommended tension for the specific industrial chain being used. This information can usually be found in the chain drive system documentation or provided by the manufacturer.

2. Measure the current tension of the chain using a tension measuring tool or gauge. This is typically done by applying a known force to a specific point on the chain and measuring the elongation or deflection.

3. Compare the measured tension with the recommended tension. If the measured tension is lower, the chain needs to be tensioned, while if it is higher, the tension needs to be reduced.

4. Adjust the tension by either increasing or decreasing the slack in the chain. This is usually done by adjusting the position of the chain tensioner or by altering the position of the chain drive components, such as the motor or sprockets.

5. Repeat the tension measurement and adjustment process until the recommended tension is achieved. It is important to ensure the tension is evenly distributed across the chain.

- Alignment:

1. Check the alignment of the chain drive components, including the motor, sprockets, and shafts. Misalignment can cause excessive wear, noise, and reduced efficiency.

2. Use alignment tools, such as laser alignment devices or straight edges, to assess the alignment of the components. The goal is to ensure that the chain runs parallel to the sprockets and that the sprockets are properly aligned with each other.

3. Make adjustments to correct any misalignment. This may involve shimming or repositioning the components to achieve proper alignment.

4. Verify the alignment by observing the chain’s movement and its interaction with the sprockets during operation. The chain should run smoothly without excessive vibration, noise, or rubbing against the sprocket teeth.

5. Regularly monitor the tension and alignment of the industrial chain drive and make necessary adjustments as part of the routine maintenance program.

Proper tensioning and alignment help minimize chain wear, reduce the risk of premature failure, and ensure smooth and efficient operation of the industrial chain drive system.

What is the load capacity of an industrial chain?

An industrial chain’s load capacity refers to the maximum amount of weight or force it can safely withstand without experiencing failure or damage. The load capacity of an industrial chain depends on several factors, including its design, construction, material, and size.

Industrial chains are engineered and manufactured to handle a wide range of load capacities, from light-duty applications to heavy-duty industrial operations. The load capacity of a specific industrial chain is typically provided by the manufacturer and can be found in product specifications or technical documentation.

The load capacity of an industrial chain is influenced by various factors, such as:

- Chain Type and Size: Different chain types, such as roller chains, silent chains, or engineering steel chains, have varying load capacities. Additionally, the size or pitch of the chain also affects its load capacity, with larger chains generally having higher load capacities.

- Chain Material and Construction: The material used to construct the chain, such as stainless steel, carbon steel, or alloy steel, affects its strength and load-bearing capacity. The chain’s construction, including the number and arrangement of links, also plays a role in determining its load capacity.

- Operating Conditions: The environment in which the industrial chain operates, such as temperature, humidity, and exposure to chemicals or corrosive substances, can impact its load capacity. Extreme conditions may require special chains with higher load ratings.

- Application Requirements: The specific application and the forces involved, such as tension, shock loads, or dynamic forces, need to be considered when determining the appropriate load capacity of an industrial chain.

To ensure the safe and efficient operation of an industrial chain, it is crucial to select a chain with an appropriate load capacity for the intended application. Exceeding the recommended load capacity can lead to premature wear, chain failure, or safety hazards. Consulting the manufacturer’s specifications and guidelines, as well as engineering calculations, can help determine the suitable load capacity for a given industrial chain.

What industries rely heavily on industrial chains?

Industrial chains play a critical role in various industries where the efficient movement of materials and products is essential. Here are some industries that heavily rely on industrial chains:

- Automotive industry: Industrial chains are used in automotive assembly lines for conveying and transferring components, as well as in engine systems for power transmission.

- Food and beverage industry: Industrial chains are widely used in food processing and packaging applications, such as conveying products, sorting, bottling, and canning.

- Mining industry: Industrial chains are utilized in mining equipment and conveyors for transporting ores, minerals, and bulk materials in harsh and demanding environments.

- Construction industry: Industrial chains are employed in construction machinery, such as cranes and excavators, for lifting heavy loads and facilitating construction operations.

- Agricultural industry: Industrial chains are essential in agricultural machinery, including tractors, combines, and harvesters, for power transmission and operating various components.

- Material handling industry: Industrial chains are widely used in material handling systems, such as conveyors, elevators, and warehouse automation, for efficient movement and sorting of goods.

- Paper and printing industry: Industrial chains are used in printing presses, bindery equipment, and paper manufacturing machines for paper handling and conveying.

- Chemical industry: Industrial chains are employed in chemical processing equipment, including mixers, reactors, and dryers, for material handling and process operations.

- Power generation industry: Industrial chains are used in power generation systems, such as steam turbines and generators, for transmitting power and controlling rotational movements.

- Textile industry: Industrial chains are utilized in textile machinery, such as weaving looms and spinning machines, for yarn movement and fabric production.

These are just a few examples, and industrial chains are found in numerous other industries where they enable efficient and reliable material handling, power transmission, and machine operation.

editor by CX 2024-03-18

China factory High Precision Conveyor Drive Transmission Roller Chain for Industrial Machine Gear

Product Description

Welcome to visit Xihu (West Lake) Dis. CHINAMFG mechanical (chain )factory .

We produce a wide range power transmission products. Such as roller chains and leaf chains, conveyor chains, drive chains, agricultural chains .

Also we can supply all kinds of industrial sprockets, chain couplings.

Established in year of 2000. With over 20 years history of specializing in the roller chains producing. With stable and good quality. We now have gained customer’s high praise from at home and abroad.

Our manufacturing plant and workshop area is over 10000 square CHINAMFG and with staff is about 70. We are the middle scale factory in China.

Our chain quality can match with GB,DIN,ASA,ANSI,JIS standard.and have gain the ISO9001 Certificate.

Till now, except for the domestic market, we have exported many chains to USA, CANADA,COLOMBIA,BRAZIL,ARGENTINA,POLAND, ITALY,SPAIN AND SO ON.

1.Standards: ISO /DIN /ANSI/GB/JIS/ASA

2. Model: 06C-35-240, 04B-48B Simplex, Duplex, Triplex AND ACCORDING TO CUSTOMER’S REQUIREMENTS

3. Materials: Carbon steel 40Mn,# 10 FOR THE ROLLER AND BUSH,40CR FOR THE PIN

4. All spare parts of chains are heat treated(quenching and tempering) and controlled in a reasonable tolerance range and suitable for the industry standard.

5. Tensile strength: more higher than the standard about 15%

6. Certificate of Quality: ISO 9001

7. Good lubrication with excellent grease.

8. Color: Self color and shot peen.

9.Can match with sprockets freely

| we are CHINAMFG chain factory from CHINA. |

| We make roller chains over 20 years. main ASA chains: — main DIN chains:06b-08b-10b-12b-16b-20b-24b-32b main motorcycle chains: H 520 520H 530 Our quality: middle level and good and stable. Follow up XIHU (WEST LAKE) DIS.HUA standard We also exported many industrial sprockets together with our chains. We mainly exported chains to South America AND Europe. |

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Surface Treatment: | Polishing |

| Structure: | Roller Chain |

| Material: | Carbon Steel |

| Type: | Short Pitch Chain |

| Samples: |

US$ 1/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does lubrication affect the performance of an industrial chain?

Lubrication plays a crucial role in the performance and longevity of an industrial chain. It provides a protective layer between the moving components of the chain, reducing friction and wear. Here are the key ways in which lubrication affects the performance of an industrial chain:

- Friction reduction: Lubrication creates a lubricating film that reduces friction between the chain’s pins, bushings, and rollers. This minimizes the resistance to movement and allows the chain to operate smoothly, reducing energy consumption and preventing excessive heat generation.

- Wear prevention: Lubrication forms a protective barrier that prevents direct metal-to-metal contact between the chain’s components. This reduces wear and extends the chain’s service life, minimizing the need for frequent replacements and costly downtime.

- Corrosion protection: Lubricants can have anti-corrosion additives that protect the chain from rust and corrosion caused by moisture, chemicals, or environmental factors. This is particularly important in applications exposed to harsh or corrosive environments.

- Noise reduction: Proper lubrication reduces the noise generated by the chain’s movement by minimizing metal-to-metal contact and damping vibrations. This is crucial in applications where noise levels need to be controlled, such as in residential areas or noise-sensitive environments.

- Temperature control: Lubrication helps dissipate heat generated during chain operation, preventing overheating and potential damage to the chain. It also provides thermal stability, allowing the chain to maintain its performance even in high-temperature environments.

- Contamination resistance: Lubrication helps repel and flush away contaminants such as dirt, dust, and debris that can accumulate on the chain. By keeping the chain clean, lubrication reduces the risk of abrasive wear and blockages that can hinder the chain’s operation.

Proper lubrication selection and maintenance are critical to ensure optimal performance and longevity of an industrial chain. It is important to follow the manufacturer’s recommendations regarding lubrication intervals, lubricant type, and application methods to achieve the best results.

How do you calculate the required length of an industrial chain?

Calculating the required length of an industrial chain involves considering several factors such as the distance between sprockets, the number of chain links, and any additional allowances for tensioning and adjustment. Here is a step-by-step process to calculate the required chain length:

- Measure the Center-to-Center Distance: Measure the distance between the center of the drive sprocket and the center of the driven sprocket. This is the center-to-center distance or pitch length.

- Determine the Number of Chain Links: Determine the number of chain links required by dividing the center-to-center distance by the pitch or the distance between adjacent chain pins.

- Add Allowances: Add allowances to account for tensioning and adjustment. The specific allowances depend on the type of industrial chain and the application requirements. Typically, an additional one or two links are added to accommodate tensioning and ensure proper chain engagement.

- Calculate the Total Chain Length: Multiply the number of chain links by the pitch or distance between adjacent chain pins. This will give you the total chain length required.

It’s important to note that industrial chains are often sold in standard lengths or in increments of a certain number of chain links. In such cases, you may need to select the nearest standard chain length that meets your calculated requirements.

It is recommended to consult the manufacturer’s guidelines, technical specifications, or engineering resources for accurate and specific calculations based on the type and size of the industrial chain being used.

How is an industrial chain different from a regular chain?

An industrial chain differs from a regular chain in terms of its design, construction, and intended application. Here are some key differences:

- Strength and Durability: Industrial chains are specifically designed to handle heavy loads and withstand harsh operating conditions in industrial settings. They are constructed using high-quality materials and undergo rigorous testing to ensure strength and durability.

- Precision Engineering: Industrial chains are engineered with precision to meet specific performance requirements. They are manufactured to strict tolerances, ensuring precise fit and proper engagement with sprockets, resulting in reliable and efficient power transmission.

- Specialized Designs: Industrial chains come in a variety of specialized designs to accommodate different applications. They may feature specific link shapes, roller configurations, or surface treatments tailored to meet the unique needs of various industries, such as conveying, lifting, or power transmission.

- Lubrication Requirements: Industrial chains often require regular lubrication to minimize friction and wear. They may incorporate lubrication systems or be designed to accommodate external lubrication methods to ensure optimal performance and longevity.

- Application Focus: Regular chains are commonly used for lighter-duty applications such as securing objects or supporting light loads. Industrial chains, on the other hand, are designed for heavy-duty industrial applications, including machinery, conveyors, mining equipment, and other demanding environments where high load capacity and reliability are crucial.

- Industry Standards and Regulations: Industrial chains are often subject to specific industry standards and regulations to ensure their performance, safety, and compatibility with machinery and equipment used in industrial settings.

Overall, the key distinction lies in the industrial chain’s robustness, precision engineering, specialized designs, and suitability for heavy-duty industrial applications, setting it apart from regular chains commonly used in lighter-duty tasks.

editor by CX 2023-12-08

China factory Stainless Steel Conveyor Chain Drop Forged Chain for Industrial Equipment

Product Description

| MODEL | P | T | t | h | H | b | d |

| S16 | 100 | 30 | 15 | 27 | 8 | 16 | 14 |

| P102-W385 | 102 | 30 | 13 | 27 | 9 | 14 | 14 |

| RUS270 | 123 | 50 | 24 | 46 | 16 | 25 | 20 20.5 |

| Z20 | 125 | 50 | 24 | 48 | 15 | 26 | 20 |

| P140 | 140 | 78 | 31 | 50 | 19 | 32 | 25 |

| Z30 | 142 | 64 | 28.5 | 50 | 18 | 30.5 | 25 |

| 150 | 150 | 38 | 18 | 40 | 10 | 20 | 18 |

| P155 | 155 | 79 | 39.5 | 63.5 | 36 | 40.5 | 30 |

| Z25 | 160 | 58 | 28 | 55 | 18 | 30 | 25 |

| YD310 | 200 | 43 | 20 | 47 | 12 | 22 | 20 |

| A-3634 | 216 | 64 | 26 | 72 | 20 | 28.5 | 35 |

| X63 | 250 | 60 | 28 | 70 | 20 | 30 | 25 |

| P260 | 260 | 72 | 32 | 75 | 20 | 34 | 32 |

ZheJiang CHINAMFG Precision Casting and Forging Inc. was established in 2003, covering an area of 40,000 square meter with 300 employees. In 2571, the company passed the quality management system certification of GB/T 19001-2016 and ISO 9001:2015, and has a number of invention patents.It is a national high-tech enterprise.

Our main products are bucket teeth,side teeth,bucket adapter for excavator and loader; Forged pipe coupling for concrete pump ; Drop forged chain for scraper conveyor, etc. Other casting and forging parts canalsobecustomized accordingto customer drawings. The main materials are alloy steel, high manganese steel, gray iron, ductile iron, etc.

Our company can produce casting range in 0.1kg-2tons, forging range in 0.1kg-100kgs, casting and forging annual capacity of 10,000tons.From productdesign, mold development to heattreatment, machining and spraying, we provide the whole processof internal manufacturing to better control the cost and quality.

ZheJiang Plus Import and Export Trading Co., Ltd. was established in 2571, is Wanxin’s subsidiary, mainly responsible for marketing and export

FAQ

Q1.Are you a manufacturer or a trading company?

we are totally manufacturer of machinery parts.

Q2.Can i get samples for checking the quality?

we can provide free samples,but you need to pay the freight.

Q3.What’s your MOQ?

For normal prodcuts,we don’t have MOQ.

For customerized products,we will tell you MOQ based on your drawing.

Q4.What’s your delivery time?

it’s about 7-45 days based on your quantity.

Q5.What’s your payment terms?

AmountAmount≥5000USD,T/T 30% as deposit,balance before delivery.

| Material: | Alloy |

|---|---|

| Structure: | Combined Chain |

| Surface Treatment: | Baking Paint |

| Chain Size: | 100 |

| Feature: | Heat Resistant |

| Process: | Forging |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can an industrial chain be used in food processing applications?

Yes, industrial chains can be used in food processing applications, but it’s important to select the right type of chain that meets the specific requirements of the application. Here are some considerations:

- Food-grade materials: When choosing an industrial chain for food processing, it is crucial to ensure that the chain is made of food-grade materials that comply with the necessary food safety standards. Stainless steel or plastic chains are commonly used in food processing due to their corrosion resistance and ease of cleaning.

- Hygienic design: Industrial chains for food processing applications should have a hygienic design that minimizes the accumulation of debris, allows for easy cleaning, and prevents the growth of bacteria. Smooth surfaces, open construction, and self-draining features are desirable.

- Chemical resistance: Food processing environments may involve exposure to various cleaning chemicals and sanitizers. The industrial chain should be resistant to these chemicals to maintain its integrity and avoid contamination.

- Temperature resistance: Depending on the food processing application, the chain may be exposed to high or low temperatures. It’s important to select a chain that can withstand the temperature range required for the specific process.

- Load capacity: Consider the load requirements of the application. Food processing operations may involve heavy loads, so the chain should have the appropriate load capacity to ensure safe and reliable operation.

- Compliance with regulations: Food processing facilities must adhere to strict regulations and standards related to food safety and hygiene. Ensure that the selected industrial chain complies with these regulations to maintain a safe and sanitary environment.

By selecting an industrial chain specifically designed for food processing applications and following proper maintenance and cleaning procedures, the chain can effectively and safely contribute to the food processing operations.

What are the common causes of industrial chain failures?

Industrial chain failures can occur due to various factors:

- Excessive load: Applying a load that exceeds the chain’s capacity can lead to stress and failure. It is important to consider the chain’s rated load and choose the appropriate chain for the application.

- Inadequate lubrication: Insufficient or improper lubrication can result in increased friction and wear, leading to premature chain failure. Regular lubrication with the recommended lubricant and following the manufacturer’s guidelines is crucial.

- Improper tensioning: Incorrect chain tension can cause misalignment, premature wear, and failure. Proper tensioning ensures optimal performance and longevity of the chain.

- Misalignment: Poor alignment between the sprockets can cause the chain to wear unevenly and increase the risk of failure. Proper alignment of the sprockets is essential for smooth operation.

- Wear and tear: Continuous use without proper maintenance and regular inspection can result in chain fatigue, elongation, and eventual failure. Regular inspection and timely replacement of worn-out components are necessary to prevent failure.

- Corrosion: Exposure to corrosive environments can weaken the chain material and compromise its integrity. Using corrosion-resistant chains or applying appropriate coatings can mitigate the risk of corrosion-related failures.

- Lack of maintenance: Neglecting routine maintenance tasks such as cleaning, lubrication, and inspection can lead to chain degradation and eventual failure. Regular maintenance is essential to ensure optimal chain performance and longevity.

How do you troubleshoot common issues with industrial chains?

Troubleshooting common issues with industrial chains involves identifying the problem, determining its cause, and taking appropriate corrective actions. Here are some common issues and troubleshooting steps:

- Chain misalignment: If the chain is misaligned, it can cause excessive wear, noise, and tension issues. To troubleshoot this, visually inspect the chain’s alignment and check if the sprockets are properly aligned. Adjust the sprockets and ensure they are aligned with the chain’s centerline.

- Chain elongation: Over time, industrial chains can elongate, leading to poor performance and increased stress on the components. To troubleshoot elongation, measure the chain’s pitch and compare it to the manufacturer’s specifications. If the chain is elongated beyond the recommended limit, it may need to be replaced.

- Inadequate lubrication: Insufficient or improper lubrication can result in increased friction and wear. Check the lubrication system and ensure the chain is properly lubricated according to the manufacturer’s recommendations. Adjust the lubrication schedule or consider using a different lubricant if necessary.

- Excessive chain tension: Excessive tension can cause increased wear, noise, and strain on the chain and components. Check the tension of the chain and adjust it to the manufacturer’s recommended specifications. Ensure proper tensioning devices, such as tensioners or idler sprockets, are in place and functioning correctly.

- Broken or damaged links: If there are broken or damaged links in the chain, they can cause performance issues and potential failure. Inspect the chain for any visible damage, such as broken pins or links, and replace the affected components as necessary.

- Excessive chain wear: Excessive wear can lead to chain elongation, decreased performance, and increased risk of failure. Regularly inspect the chain for signs of wear, such as elongation, worn sprocket teeth, or excessive clearance between the chain and sprockets. Replace the chain if it has reached its wear limit.

It is important to consult the manufacturer’s guidelines and recommendations for troubleshooting specific issues with the particular type of industrial chain being used. Additionally, regular maintenance, including proper lubrication, tensioning, and periodic inspections, can help prevent common issues and prolong the lifespan of the industrial chain.

editor by CX 2023-11-20

China OEM Manufacturer From China of Overhead Detachable Drop Forged Conveyor Chain for Slaughtering Line (X348 X458 X658 X678 X698 F100 F160)

Product Description

About Factory

With more than 18 years’ histiory, we are a professinal manufacturer for drop forged products such as forged chain (X348 X458 X658 X678 X698 F100 F160), scraper chain (10160, 14218, 14226, 142N), conveyor trolley (X348, X458, X678, XT160), and drive chain (X348, X458, X678), and so forth standard moulds of chain.

Besides, we can also produce as per your drawing or sample, special link chain, pusher, pin and plate, according to customers’ unique requirements.

Product Description

1) Material: Alloy steel, 40Cr, 42CrMo and so on.

2) Types: X348 X458 X658 X678 X698 F100 F160, and so on. (Or as per your drawing)

3) Process: Moulding→Forging→Polishing & Blasting→Fine machining→Heat treatment→Blasting→Inspecting & testing→Packing

Product Show

Technical Data

| Model | Pitch | Dimension | Lateral Corner | Standard Measured Length (mm) | Measured Quantity | Tensile Strength (KN) | Weight (Kg/m) | |||||

| A | F | G | J | K | S | |||||||

| 80H | 80 | 73 | 42 | 18.4 | 20 | 34.5 | 19.5 | 7 | 3032/3058 | 38 | 250 | 7.8 |

| X348 | 76.6 | 46 | 27 | 12.7 | 12.7 | 20.6 | 13.5 | 9 | 3050.5/3095.2 | 40 | 110 | 3.2 |

| X458 | 102.4 | 57 | 37 | 16 | 16 | 26.5 | 17.5 | 9 | 3063.1/3090.2 | 30 | 210 | 5.2 |

| 468H | 102.4 | 84.1 | 47.8 | 18 | 29.5 | 42.9 | 22.2 | 9 | 3063.1/3090.2 | 30 | 318 | 11.5 |

| X658 | 153.2 | 55.6 | 35 | 16 | 16 | 57.2 | 17.5 | 7 | 3055.1/3082.8 | 20 | 210 | 4 |

| X678 | 153.2 | 77 | 50.8 | 22.2 | 21 | 34.2 | 25 | 7 | 3055.1/3082.8 | 20 | 320 | 9.5 |

| 678 | 153.2 | 77 | 50.8 | 22.2 | 21 | 34.2 | 25 | 7 | 3055.1/3082.8 | 20 | 320 | 9.5 |

| 698 | 153.2 | 95.25 | 64 | 28 | 25.4 | 41.3 | 32 | 5 | 3055.1/3082.8 | 20 | 515 | 17 |

| 998 | 229.4 | 95.25 | 67.5 | 28 | 25.4 | 41.3 | 32 | 5 | 3205/3232.4 | 13 | 515 | 14.8 |

| 9118 | 229.4 | 123.8 | 76.2 | 35 | 33.5 | 52 | 38.1 | 5 | 3205/3232.4 | 13 | 832 | 24.2 |

| S348 | 76.6 | 38.9 | 28.6 | 12.7 | 12.7 | 20.6 | 13.5 | 9 | 3050.5/3095.2 | 40 | 110 | 3.2 |

| S458 | 102.4 | 52.1 | 35 | 16 | 16 | 26.5 | 17.5 | 9 | 3063.1/3090.2 | 30 | 210 | 5.2 |

| S678 | 153.2 | 69.8 | 50.8 | 22.2 | 21 | 34.2 | 25 | 7 | 3055.1/3082.8 | 20 | 320 | 9.5 |

| S698 | 153.2 | 73 | 68.3 | 28 | 25.4 | 41.3 | 32 | 5 | 3055.1/3082.8 | 20 | 515 | 17 |

| S9118 | 229.4 | 98.4 | 77.8 | 35 | 33.5 | 52 | 38.1 | 5 | 3205/3232.4 | 13 | 832 | 24.2 |

| F100 | 100 | 57 | 37 | 16 | 16 | 26.5 | 17.5 | 9 | 2991.3/3018.3 | 30 | 210 | 5.2 |

| F160 | 160 | 78 | 54 | 24 | 20.5 | 36 | 28 | 7 | 3190.7/3219.5 | 20 | 318 | 10.3 |

Products & Testing Equipments

Products Application

Packing & Delivery

Why Choose Us?

1. We are engaged in chain industry over 15 years with rich market experience. We keep improving production techniques. All the products have longer working life and have passed the market test.

2. We can design the correct chains with high quality material, good abrasion resistance, good corrosion, high strengthen and etc as per your request or the chain application.

3. We are the chain manufacturer; you can directly purchase the product from us with low price and high quality.

4. We have a professional team for international trade, they have abundant experiences and are always ready to solve problems for customers. So you have nothing to worry about.

5. We have the long-term cooperative forwarder who can give us the lowest freight. And it can help you to save the freight. What’s more, for the FCL, we will design the packages as per the container sizes with the largest capacity to save the shipping cost for both of us.

| Material: | Alloy |

|---|---|

| Structure: | Combined Chain |

| Surface Treatment: | Polishing |

| Chain Size: | 1/2"*11/128" |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Mould Number: | X458X348 X458 X658 X678 X698 F100 F160 |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the future trends and advancements in industrial chain technology?

Industrial chain technology is continuously evolving to meet the changing needs of various industries. Here are some future trends and advancements that can be observed in industrial chain technology:

- Increased Automation: Industrial chains are becoming an integral part of automated systems. The advancement of robotics, IoT (Internet of Things), and artificial intelligence is driving the integration of industrial chains with smart technologies. This includes features such as remote monitoring, predictive maintenance, and real-time data analysis for optimizing chain performance and overall system efficiency.

- Improved Materials and Coatings: Ongoing research and development efforts are focused on developing advanced materials with enhanced properties for industrial chains. This includes materials with superior strength, durability, corrosion resistance, and wear resistance. Additionally, the development of advanced surface coatings and treatments further enhances the performance and lifespan of industrial chains.

- Energy Efficiency: Energy efficiency is a growing concern in industrial applications. Future industrial chains are likely to incorporate designs and features that reduce energy consumption, such as optimized chain profiles, reduced friction coatings, and improved lubrication systems. These advancements aim to minimize power losses and improve overall system efficiency.

- Integration with Digital Technologies: Industrial chains are expected to be increasingly integrated with digital technologies for seamless communication and data exchange. This integration enables better monitoring of chain performance, real-time diagnostics, and the ability to make data-driven decisions for maintenance and optimization. Digital twins, virtual simulations, and augmented reality (AR) are also emerging trends that allow for improved chain design, testing, and troubleshooting.

- Enhanced Safety Features: Safety remains a top priority in industrial settings. Future industrial chains may incorporate advanced safety features such as integrated sensors for detecting chain wear, overload conditions, or abnormal operating parameters. These features can provide early warning signs and help prevent accidents or equipment failures.

The future of industrial chain technology is driven by the need for increased efficiency, reliability, and safety. The integration of smart technologies, improved materials, energy efficiency measures, digitalization, and enhanced safety features are expected to shape the advancements in industrial chain technology in the coming years.

What safety precautions should be followed when working with industrial chains?

Working with industrial chains involves potential hazards, and it is important to follow proper safety precautions to prevent accidents and injuries. Here are some safety guidelines to consider:

- Training and Familiarization: Ensure that workers are properly trained in handling industrial chains, including understanding the risks involved and knowing how to operate, maintain, and inspect them correctly.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as safety glasses, gloves, and steel-toed shoes, to protect against potential hazards, including flying debris, pinch points, and sharp edges.

- Equipment Inspection: Regularly inspect the industrial chain, sprockets, and other related equipment for any signs of damage, wear, or misalignment. If any issues are found, repair or replace the components before using the chain.

- Proper Installation: Follow the manufacturer’s instructions and guidelines for proper installation of the industrial chain, including correct tensioning, alignment, and lubrication. Ensure that the chain is securely attached and that all connections and fasteners are properly tightened.

- Safe Operating Procedures: Adhere to safe operating procedures when using machinery or equipment with industrial chains. Avoid operating the machinery at excessive speeds or overloading the chain beyond its recommended capacity.

- Lockout/Tagout: When performing maintenance or repairs on machinery with industrial chains, follow lockout/tagout procedures to ensure the equipment is de-energized and cannot be accidentally started.

- Avoid Loose Clothing and Jewelry: Do not wear loose clothing, jewelry, or any other items that can get caught in the chain or machinery, posing a risk of entanglement.

- Emergency Stop Devices: Ensure that emergency stop devices are easily accessible and functional to quickly halt the machinery in case of an emergency or entanglement.

- Regular Maintenance: Implement a regular maintenance program to inspect and maintain industrial chains, including lubrication, tensioning, and replacing worn or damaged components.

It is crucial to consult and follow all relevant safety regulations and guidelines specific to your industry and location. Additionally, fostering a safety-conscious work environment, providing proper training and supervision, and promoting a culture of safety awareness among workers can contribute to the prevention of accidents and injuries when working with industrial chains.

What materials are commonly used in industrial chains?

Industrial chains are constructed using various materials to meet specific application requirements. The choice of material depends on factors such as load capacity, environmental conditions, corrosion resistance, and temperature resistance. Here are some commonly used materials in industrial chains:

- Carbon Steel: Carbon steel is widely used in industrial chains due to its strength, durability, and affordability. It offers good resistance to wear and can handle moderate loads in standard operating conditions.

- Alloy Steel: Alloy steels are alloyed with other elements to enhance their mechanical properties, such as increased strength, hardness, and wear resistance. Alloy steel chains are commonly used in heavy-duty applications where higher load capacities and greater toughness are required.

- Stainless Steel: Stainless steel chains are highly corrosion-resistant and are suitable for applications where exposure to moisture, chemicals, or high temperatures is a concern. They offer excellent durability and can withstand harsh environments, making them ideal for industries such as food processing, pharmaceuticals, and marine applications.

- Plastic: Plastic chains, typically made from engineering-grade polymers such as acetal or nylon, are lightweight, corrosion-resistant, and offer low friction. They are often used in applications where reduced noise, lubrication-free operation, and resistance to chemicals or moisture are desired.

- Specialty Alloys: In specific industries or applications with extreme conditions, specialty alloys such as stainless steel alloys, nickel alloys, or heat-resistant alloys may be used to provide exceptional strength, corrosion resistance, or temperature resistance.

It’s important to consider the material compatibility with the environment, load requirements, and other factors when selecting an industrial chain for a particular application. Consulting with manufacturers or industry experts can help determine the most suitable material for specific industrial chain needs.

editor by CX 2023-11-17

China Best Sales Industrial Cheap X348 X458 X678 Chip Wood Slat Conveyor Chain Trolley Overhead Conveyor Drive Chain for Sale

Product Description

Detailed Photos

Product Description

| MODEL | UH-5075-S | UH-5075-HH | UH-5075-HV | UH-5075-HA |

| ITEM | Standard chain | Heavy-duty chain | Heavy-duty chain | Heavy-duty chain |

| Suspension Spacing | 150+(150× N) | 150+(150× N) | 150+(150 × N) | 150+(150 × N) |

| (mm) | ||||

| Chain’s Weight | 4.2 | 4.58 | 4.83 | 5.3 |

| (kg/m) | ||||

| Single-span Weight | 35 | 40 | 45 | 50 |

| (≤kg) | ||||

| Chain’s Allowed | 3000 | 3000 | 3000 | 3000 |

| Pull Force (≤kgf) | ||||

| Chain’s Catastrophic | 5500 | 5500 | 5500 | 5500 |

| Pull Force (≥kgf) | ||||

| Working temperature | 300 | 300 | 400 | |

| (≤°C) | 250 | |||

| Applicable Equipment | General conditions | Large bending; | High temperature; | High temperature; |

| High temperature; | Heavy work piece; | Heavy work piece; | ||

| Frequently lifted; | Complicated route; | |||

| Material | 16# Medium-carbon steel, Steel A3 | |||

| Remark: The above technical data is for our usual hanging type conveyors: UH-5S, UH-5HH, VH-5HA type. We can customize design and manufacture the products based customers particular requirements. | ||||

The overhead conveyor components including drop forged rivetless chain, drop forged overhead trolley, drive chain, trolley attachment, side link pusher dog, rollers turn roller, enclosed track chain, free carrier trolley and so on.

We can also supply other conveyor and transmission parts to fit our customer’s specific needs, including conveyor chain, stainless steel chain, cast chain, drop forged scraper chain, forged loop chain, bi-planar conveyor chain, sprockets, bearings, forged gear, special shaft, outboard roller assembly, conveyor roller, special brass parts and so on.

Main sizes are P101.6 Chain, P101.6H Chain, P142 chain, P142H Chain, P200 chain, P260 Chain and so on.

Our drop forged rivetless chain are most competitive and are of high quality. There are many items available. Please feel free to contact us.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 30 workdays.

2.Production Lead-times: 60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We’ll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we’ll check

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Chain Size: | 1/2"*3/32" |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Product Name: | Overhead Conveyor Chains |

| Customization: |

Available

| Customized Request |

|---|

Can an industrial chain be used for heavy-duty applications?

Yes, an industrial chain is commonly used in heavy-duty applications due to its ability to handle high loads and provide reliable power transmission. Here are some detailed reasons why industrial chains are suitable for heavy-duty applications:

- High Load Capacity: Industrial chains are designed to withstand heavy loads and transmit power efficiently. They are constructed with robust materials and components to ensure they can handle the demanding conditions of heavy-duty applications.

- Strength and Durability: Industrial chains are manufactured from high-strength materials such as alloy steel, which provides exceptional tensile strength and resistance to wear and fatigue. This allows them to withstand the stresses and strains associated with heavy loads and continuous operation.

- Reliable Power Transmission: Industrial chains offer a reliable and efficient means of transmitting power in heavy-duty applications. They provide a positive engagement between the sprockets, ensuring smooth and consistent power transfer even under high loads.

- Versatility: Industrial chains can be designed and configured to meet the specific requirements of different heavy-duty applications. They are available in various sizes, designs, and types, allowing for customization and adaptation to specific load conditions and operating environments.

- Proven Track Record: Industrial chains have been widely used in heavy-duty applications across industries such as construction, mining, agriculture, and material handling. Their reliability and performance in demanding conditions have been well-documented, making them a trusted choice for heavy-duty applications.

Overall, the robust construction, high load capacity, strength, durability, and proven performance make industrial chains a suitable choice for heavy-duty applications where reliable power transmission and handling of high loads are essential.

How do you select the appropriate lubricant for an industrial chain?

Selecting the right lubricant for an industrial chain is crucial to ensure its smooth operation, reduce wear, and extend its lifespan. Here are the key factors to consider when choosing the appropriate lubricant:

1. Chain type: Different types of industrial chains may have specific lubrication requirements. Refer to the manufacturer’s recommendations or technical specifications to determine the compatible lubricant.

2. Operating conditions: Consider the operating environment, such as temperature, humidity, and exposure to contaminants like dust or chemicals. Choose a lubricant that can withstand the specific conditions and provide adequate protection.

3. Load and speed: Evaluate the load capacity and speed of the chain system. High loads or high speeds may require lubricants with enhanced film strength and viscosity to prevent metal-to-metal contact.

4. Lubricant properties: Look for lubricants with properties such as high viscosity index, good thermal stability, anti-wear additives, corrosion resistance, and water resistance. These properties contribute to better lubrication and protection.

5. Lubrication method: Consider the lubrication method available for the chain system, such as manual lubrication, automatic lubrication systems, or oil bath lubrication. Ensure the selected lubricant is compatible with the chosen lubrication method.

6. Maintenance schedule: Assess the maintenance intervals and frequency of lubrication. Some lubricants offer longer-lasting performance, reducing the frequency of relubrication and maintenance requirements.

7. Environmental impact: Take into account any environmental regulations or considerations when selecting a lubricant. Choose environmentally friendly options, such as biodegradable or low-toxicity lubricants, if required.

Consult with lubricant suppliers or industry experts for specific recommendations based on your application and chain system requirements. They can provide valuable insights and help you select the most suitable lubricant to optimize the performance and longevity of your industrial chain.

What are the advantages of using an industrial chain in industrial settings?

An industrial chain offers several advantages that make it a popular choice in industrial settings. Here are some key benefits:

- High load capacity: Industrial chains are designed to handle heavy loads and provide reliable power transmission, making them suitable for applications that require robust and durable components.

- Wide range of applications: Industrial chains find application in various industries, including manufacturing, automotive, mining, construction, agriculture, and more. They can be used for conveying, lifting, driving, and transferring power in different types of machinery and equipment.

- Efficient power transmission: Industrial chains have high efficiency in transferring power from one component to another, minimizing energy loss and maximizing the overall performance of the machinery.

- Flexible design: Industrial chains come in different sizes, configurations, and materials, allowing for flexibility in design and accommodating various application requirements. They can be customized to fit specific needs, offering versatility in industrial settings.

- Durable and long-lasting: Industrial chains are built to withstand heavy-duty operations and harsh environments. They are constructed using high-quality materials and undergo heat treatment or surface hardening processes to enhance their strength, durability, and resistance to wear and fatigue.

- Reliable and low-maintenance: Industrial chains are designed for continuous operation with minimal maintenance. Proper lubrication and periodic inspection are typically sufficient to ensure their reliable performance and extend their service life.

- Cost-effective: Industrial chains provide a cost-effective solution for power transmission compared to other alternatives. They have a relatively low initial cost, require less maintenance, and have a long lifespan, resulting in reduced downtime and overall operational costs.

- Easy installation and replacement: Industrial chains are designed for ease of installation and replacement. With standardized dimensions and readily available components, they can be quickly installed or replaced, minimizing downtime and maximizing productivity.

Overall, industrial chains offer durability, versatility, and efficiency, making them a preferred choice in industrial settings where reliable power transmission and heavy-load handling are required.

editor by CX 2023-11-10

China factory 10A-K1 Attachment Conveyor Chain for Industrial Automation Production

Product Description

| 1)Type | conveyor chain |

| 2)Materials | Carbon steel |

| 3)Chain No. | 10A-K1 |

| 4)Application | Industrial machinery |

| 5)Process | High speed impact, heat treatment, Pre-stretching and running Four sides riveting, Lubricate with Grease |

| 6)MOQ | 1000Pcs |

| 7)Supply Ability | 100000Meters per year |

| 8)Tensile Strength/Hardness | standard or above |

| 9)Delivery Time | within 30 days after receiving your 30% deposits |

| 10)Payment Terms | L/C,T/T |

| 11)Packing | chains packing in standard export carton, also can packing as your requirement |

Our Services

Pre-sales:

1. OEM &ODM service

2. Any of your kind inquiry would be replied within 24 hours.

3. Complete product information will be offered

4. Free sample will be sent if you need .

5. Any other reasonable requirements as per requested

During production ,we provide:

1. Schedule of production

2. Mass production picture will offered

3. Any other reasonable requirements as per requested

Finish production:

1. Courier tracking number

2. Documents you need

3. Protection of your sales area, ideas of design and all your private information.

FAQ:

Q1: Do you inspect the finished products?

A: Yes, each step of production and finished products will be carried out inspection by QC departing before shipping.

Q2: What’s the warranty of your products?

A: Usually we guarantee one year after delivery date, but depending on the specified product.

Q3: Are you manufacturer or Trade Company?

A: Both we are. We have been in motorcycle parts for nearly 20 years.

Q4: How to visit factory?

A: Leave us a message, and we will pick you up by car for free.

Q5: Can you do custom logo on the chain?

A: Yes,we can do custom logos by molding. Need your Authorization Letter

| Material: | Grade a Steel |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Electroplating |

| Transport Package: | Polybag + Color Box + Carton |

| Trademark: | customizable trademark |

| Origin: | China |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you troubleshoot chain skipping or slipping issues in an industrial chain?

Chain skipping or slipping issues in an industrial chain can lead to decreased efficiency and potential equipment damage. Here are some steps to troubleshoot and address these issues: