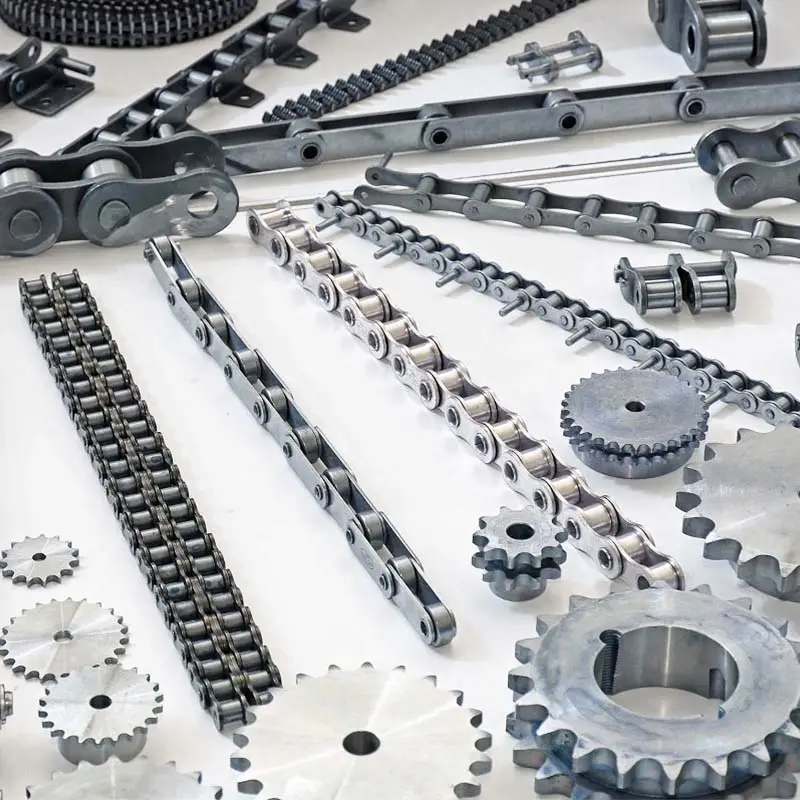

Product Description

China Factory Industrial Machine CHINAMFG Lifting Load Hoist Chain

Specifications

| Calibrated Hoist Chain(GRADE 80) standard EN818-7 | ||||||

| Zize dxp (mm) | Width | Approx weight (kg/m) | Working LoadLimit(t) | Test Load(kN) | BreakingLoad min.KN | |

| Inside min.w1 | Inside max.w3 | |||||

| 3*9 | 3.8 | 10.7 | 0.21 | 0.28 | 7.1 | 11.3 |

| 4*12 | 5 | 14.3 | 0.35 | 0.5 | 12.6 | 20.1 |

| 5*15 | 6.3 | 17.9 | 0.54 | 0.8 | 19.6 | 31.4 |

| 6*18 | 7.5 | 21 | 0.79 | 1.1 | 27 | 45.2 |

| 6.3*19 | 7.9 | 22.6 | 0.86 | 1.25 | 31.2 | 49.9 |

| 7*21 | 9 | 24.5 | 1.07 | 1.5 | 37 | 61.6 |

| 8*24 | 10 | 28 | 1.38 | 2 | 48 | 80.4 |

| 9*27 | 11.3 | 32.2 | 1.76 | 2.5 | 63.6 | 12 |

| 10*30 | 12.5 | 35 | 2.2 | 3.2 | 76 | 125 |

| 11.2*33.6 | 14 | 40.1 | 2.71 | 4 | 98.5 | 158 |

| 11*43 | 12.6 | 36.5 | 2.33 | 3.8 | 92 | 154 |

| 12*36 | 15 | 42 | 3.1 | 4.6 | 109 | 181 |

| 12.5*38 | 15.5 | 42.2 | 3.3 | 4.9 | 117 | 196 |

| 13*39 | 16.3 | 46 | 3.8 | 5 | 128 | 214 |

| 14*42 | 18 | 49 | 4.13 | 6.3 | 150 | 250 |

| 14*50 | 17 | 48 | 4 | 6.3 | 150 | 250 |

| 15*46 | 20 | 52 | 5.17 | 7 | 168 | 280 |

| 16*48 | 20 | 56 | 5.63 | 8 | 192 | 320 |

| 16*49 | 24.5 | 59.5 | 5.71 | 8 | 192 | 320 |

| 16*64 | 23.9 | 58.9 | 5.11 | 8 | 192 | 320 |

| 18*54 | 23 | 63 | 6.85 | 10 | 246 | 410 |

| 18*54 | 21 | 60 | 6.6 | 10 | 246 | 410 |

| 19*57 | 23.7 | 63.2 | 7.7 | 11.3 | 270 | 450 |

| 20*60 | 25 | 70 | 8.6 | 12.5 | 300 | 500 |

| 22*65 | 28 | 74.2 | 10.7 | 15.3 | 366 | 610 |

| 22*66 | 28 | 77 | 10.2 | 15.3 | 366 | 610 |

| 22*86 | 26 | 74 | 9.5 | 15.3 | 366 | 610 |

| 24*72 | 32 | 82 | 12.78 | 18 | 432 | 720 |

| 24*86 | 28 | 79 | 11.6 | 18 | 432 | 720 |

| 26*78 | 35 | 91 | 14.87 | 21.3 | 510 | 720 |

| 26*92 | 30 | 86 | 13.7 | 21.3 | 510 | 850 |

Payment

| Payment term | L/C | l/c amount above 40.000 usd,we can accept L/C at sight | |

| T/T |

EXW | 30% T/T in advance,paid the balance before shipment |

|

| FOB | |||

| CIF | 30% T/T in advance,paid the balance against copy of B/L |

||

| cfr(c&f) | |||

| paypal | amount lower than 4000usd |

||

| west | |||

| Delivery time | 15~35days after receiving payment for 1 container |

| We welcome use trade assurance,you`ll enjoy: 100% product quality protection 100% on-time shipment protection 100% payment protection for your covered amount |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain, Drag Chain, Conveyor Chain, Dedicated Special Chain |

|---|---|

| Material: | 20mn2 |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant |

| Chain Size: | Standard |

| Structure: | Combined Chain |

| Samples: |

US$ 5/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the factors to consider when selecting the pitch of an industrial chain?

The pitch of an industrial chain refers to the distance between adjacent pins or rollers on the chain. When selecting the pitch of an industrial chain, several factors should be considered:

- Load requirements: The pitch of the chain should be selected based on the expected load that the chain will need to carry. Higher loads typically require larger pitch sizes to ensure sufficient strength and durability.

- Speed of operation: The chain’s pitch should be chosen based on the speed at which the chain will be operating. Higher speeds may require smaller pitch sizes to maintain smooth and efficient operation.

- Space limitations: The available space for the chain system should be considered when selecting the pitch. Smaller pitch sizes can accommodate tighter spaces, while larger pitch sizes may be suitable for applications with more ample space.

- Application requirements: The specific requirements of the application should be taken into account. Factors such as the type of load being transported, the operating environment (temperature, moisture, etc.), and any special considerations (e.g., noise reduction, corrosion resistance) can influence the pitch selection.

- Chain compatibility: It is essential to ensure that the selected chain pitch is compatible with the sprockets or gears used in the system. The chain and sprocket/gear pitch should match to ensure proper engagement and efficient power transmission.

- Service life expectations: Consideration should be given to the desired service life of the chain. In applications with high-cycle operations or demanding conditions, selecting a chain with a smaller pitch size or a specialized design may be necessary to enhance longevity.

By carefully considering the load requirements, speed of operation, space limitations, application requirements, chain compatibility, and service life expectations, one can select the appropriate pitch size for an industrial chain that ensures optimal performance and reliability.

What is the load capacity of an industrial chain?

An industrial chain’s load capacity refers to the maximum amount of weight or force it can safely withstand without experiencing failure or damage. The load capacity of an industrial chain depends on several factors, including its design, construction, material, and size.

Industrial chains are engineered and manufactured to handle a wide range of load capacities, from light-duty applications to heavy-duty industrial operations. The load capacity of a specific industrial chain is typically provided by the manufacturer and can be found in product specifications or technical documentation.

The load capacity of an industrial chain is influenced by various factors, such as:

- Chain Type and Size: Different chain types, such as roller chains, silent chains, or engineering steel chains, have varying load capacities. Additionally, the size or pitch of the chain also affects its load capacity, with larger chains generally having higher load capacities.

- Chain Material and Construction: The material used to construct the chain, such as stainless steel, carbon steel, or alloy steel, affects its strength and load-bearing capacity. The chain’s construction, including the number and arrangement of links, also plays a role in determining its load capacity.

- Operating Conditions: The environment in which the industrial chain operates, such as temperature, humidity, and exposure to chemicals or corrosive substances, can impact its load capacity. Extreme conditions may require special chains with higher load ratings.

- Application Requirements: The specific application and the forces involved, such as tension, shock loads, or dynamic forces, need to be considered when determining the appropriate load capacity of an industrial chain.

To ensure the safe and efficient operation of an industrial chain, it is crucial to select a chain with an appropriate load capacity for the intended application. Exceeding the recommended load capacity can lead to premature wear, chain failure, or safety hazards. Consulting the manufacturer’s specifications and guidelines, as well as engineering calculations, can help determine the suitable load capacity for a given industrial chain.

What lubrication is recommended for industrial chains?

Choosing the right lubrication for industrial chains is essential to ensure their smooth operation and longevity. Here are some commonly recommended lubricants for industrial chains:

- Chain Oil: Chain oils are specifically formulated for industrial chain applications. They have excellent penetration and adhesion properties, providing lubrication to the chain’s internal components. Chain oils often have anti-wear and anti-corrosion additives to protect against friction and moisture.

- Grease: Greases designed for industrial chain lubrication offer good adhesion and cling properties. They provide a protective film that stays in place even under high loads and temperatures. Greases can provide long-lasting lubrication and are suitable for applications where oil may not be suitable or accessible.

- Dry Film Lubricants: Dry film lubricants, such as PTFE (polytetrafluoroethylene) or molybdenum disulfide-based coatings, are applied as a thin film to the chain. They create a low-friction barrier between the chain components, reducing wear and enhancing performance. Dry film lubricants are particularly useful in applications where oil or grease may attract dirt, dust, or contaminants.

When selecting a lubricant for industrial chains, consider factors such as operating conditions, temperature, load, speed, and environmental conditions. It’s important to consult the chain manufacturer’s recommendations and follow their guidelines for lubrication intervals and application methods. Regular lubrication and maintenance will help reduce friction, wear, and the risk of chain failures in industrial applications.

editor by CX 2024-04-26